Miniature 60 kV, 1000 μA 12 W X-ray Source

Application Notebook

Moxtek's MAGPRO miniature X-ray source is capable of up to 60 kV 200 µA and down to 4 kV and 1000 µA, and limited to an output power of 12 watts. The 12 W source is meant for use in small bench top systems where small size is valued.

Moxtek's MAGPRO miniature X-ray source is capable of up to 60 kV 200 µA and down to 4 kV and 1000 µA, and limited to an output power of 12 watts. The 12 W source is meant for use in small bench top systems where small size is valued.

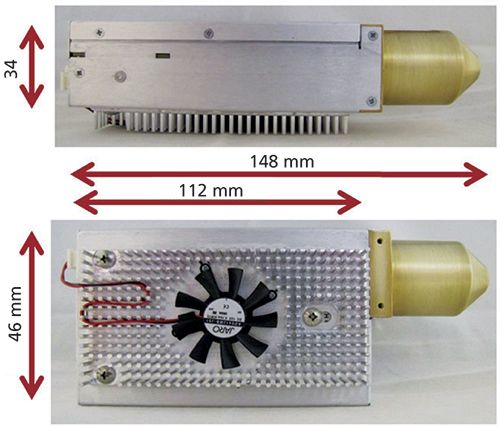

The 12 W miniature source has a higher voltage and a much higher emission current than our present miniature X-ray sources, which is an advantage for a number of applications. The initial release of the 12 W source, our MXDPP-50 electronics comes in two versions: the tungsten anode version, which can be used in either XRF or in X-ray imaging, and the Rh anode version, primarily meant for light element XRF detection (Figure 1). The entire X-ray source (tube plus high voltage power supply) weighs about 700 g (25.0 oz) and can be controlled by your choice of USB, digital, or analog control. It also has an interlock connection for X-ray safety.

Figure 1: Image of the 12 W X-ray source.

We will show the advantage of the rhodium anode source running at 4 kV 1000 µA for XRF of cement powders.

Experimental Conditions and Results for XRF Detection of Cement Powers

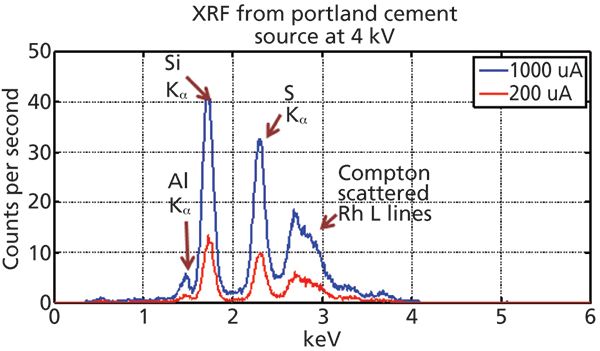

Concentrations of sulfur (sulfate), silicon (silicon dioxide), and aluminum (aluminum oxide) are important for both identifying and controlling different blends of cement powder. XRF can be used to measure cement powder elemental concentrations. XRF for the desired "light" elements, with emission lines under about 4 keV is challenging because the characteristic X-rays are absorbed by air, thereby attenuating the signal from the sample. For this experiment, we used a typical XRF setup where the sample is placed at 45° to the tube, and 135° to the detector, and no filters on the 12 W X-ray source. For light element XRF, a rhodium anode is often used because it has L emission lines between 2.7 and 3.0 keV, which are used to excite elements with emission lines below 2.5 keV. For this test the 12 W X-ray source was set to the minimum of 4 kV, which is helpful in eliminating the calcium XRF signal from the cement. The calcium signal is unwanted in this application because it will overwhelm the detection of the other elements of interest. A high emission current X-ray source, such as 1000 µA from the 12 W source, is very helpful in increasing the signal.

Figure 2 shows an XRF spectrum from a Portland cement sample with the 12 W source running at 1000 µA and 200 µA on a rhodium anode tube. The signal level is increased by a bit over fivefold for these light elements, which can be a huge advantage in any application which detection of light elements is needed.

Figure 2: Running at 1000 µA, the 12 W source produces much more signal from the desired elements in the cement powder than running at 200 µA.

Conclusions

The new 12 W source is meant for use in small benchtop systems where small size is valued. It has as increased range up to 60 kV at high voltage and increased current to 1000 µA at low voltages; both of which are an advantage in XRF and imaging applications.

Moxtek

452 West 1260 North, Orem, UT 84057

tel. (800) 758-3110, email: info@moxtek.com

Website: www.moxtek.com

The 2024 Emerging Leader in Atomic Spectroscopy Award

January 1st 2024This year’s Emerging Leader in Atomic Spectroscopy Award recipient is Eduardo Bolea-Fernández. For the past decade, Bolea-Fernández’s research has focused on the development of a newly introduced technique, termed tandem ICP-mass spectrometry (ICP-MS/MS), for ultra-trace elemental and isotopic analysis. Senior technical editor Jerome Workman discusses Bolea-Fernández’s work here.

Advancements in Non-Invasive Analysis of Historical Metal Artifacts

December 19th 2023Studying historical ancient artifacts requires the use of a nondestructive technique to analyze the metal surfaces of these objects. This study presents two approaches that improves on existing methods when conducting alloy analysis.