Characterization of Surface Orientation of a Molded Polymer by FTIR-ATR

Thermotropic liquid crystal polymers (TLCP) are injection molded and undergo spontaneous ordering while flowing through the mold. The degree of orientation depends on the distance from the injection point, the depth into the material, and other factors. Since the orientation changes the physical properties of the product, it is important to control the degree of anisotropy. This application note demonstrates using ATR to examine the changes in surface orientation as a function of the distance from the injection point or gate.

Experimental

Samples of the TLCP were cut down the centerline of the mold, 15 mm apart, and cleaned using Alconox™ in an ultrasonic bath to remove surface contaminants.

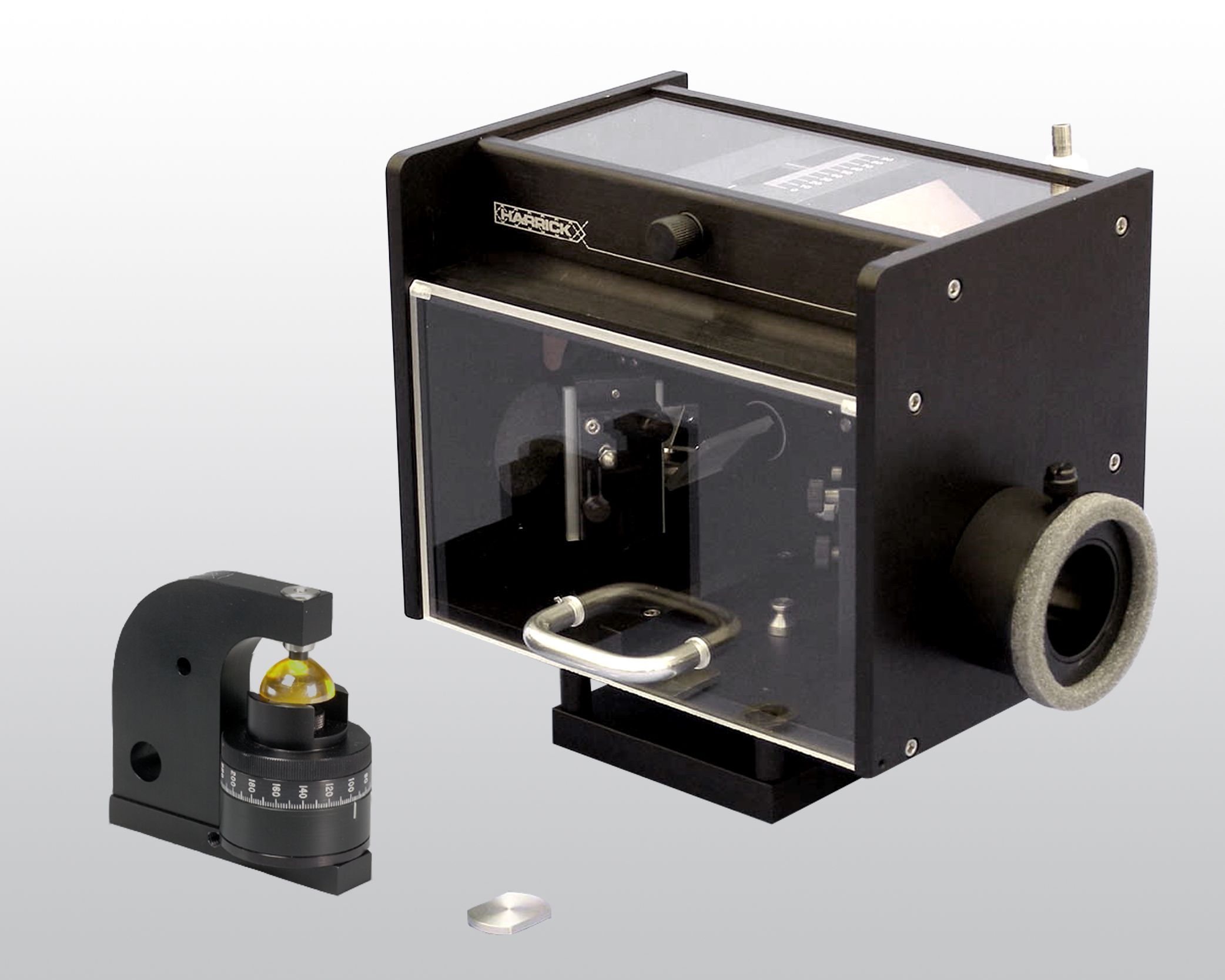

Infrared spectra were collected on an FT-IR spectrometer equipped with the Seagull variable angle reflection accessory with its ATR rotator (Figure 1), ZnSe ATR crystal, and KRS-5 wire grid polarizer set to s-polarization. The Seagull was used at a 55° incident angle. The spectrometer collected data at 4 cm-1 resolution, signal averaged over 32 scans.

Figure 1: The Seagull with its ATR rotator.

A background was collected from the clean ATR crystal. Each sample was oriented on the ATR rotator so its cut edges corresponded to the 0° and 90° setting. Sample spectra were collected at 0°, 45°, and 90°.

Results and Discussion

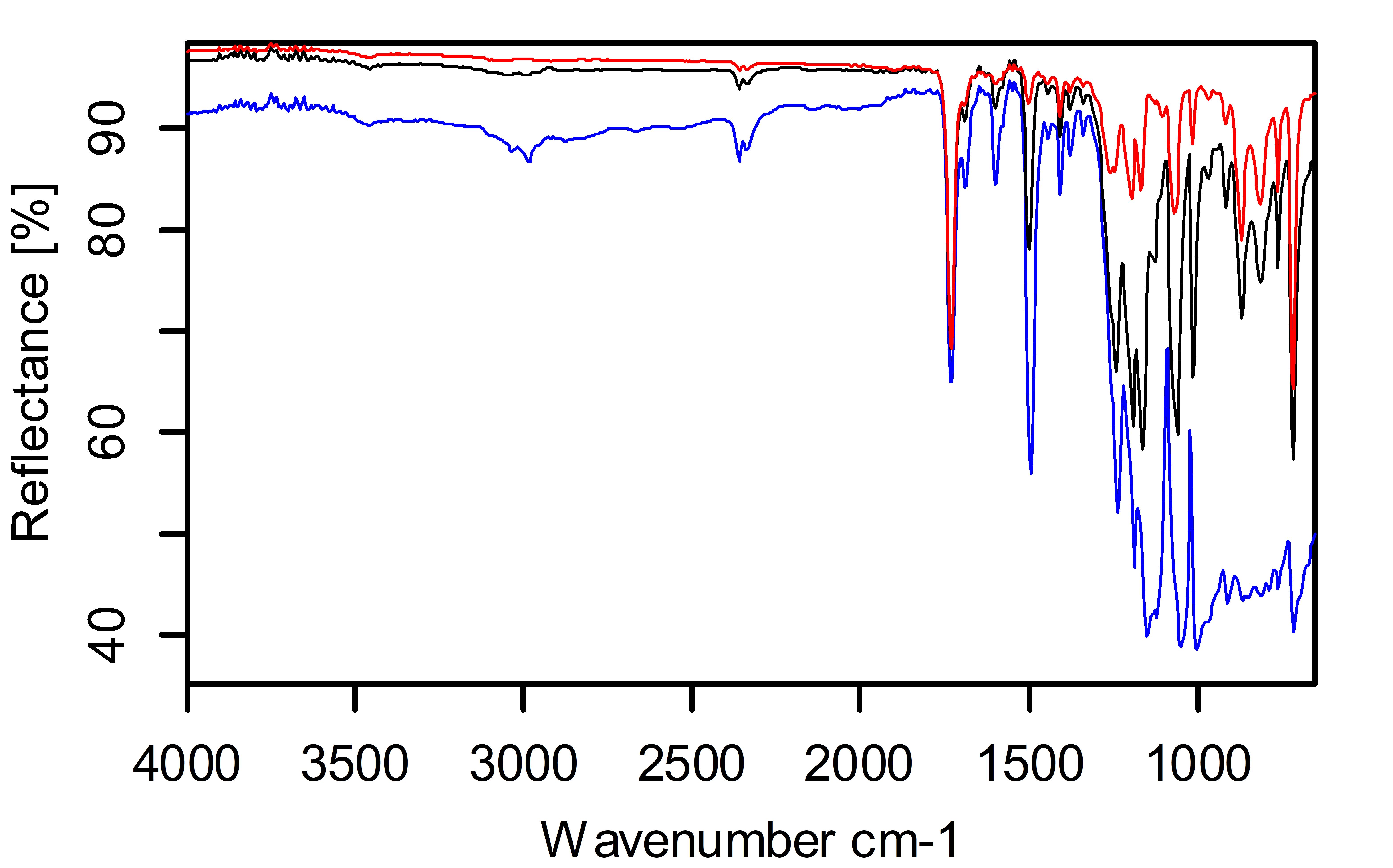

Figure 2 shows the data collected from the sample farthest (60 mm) from the gate. The band at 1500 cm-1 shows the most striking change. It is much weaker at the 0° position than at the 90° position. This band is due to the skeletal vibration of the benzene and naphthalene rings in the TLCP, which are oriented relative to the polymer chain axes. The band at 1730 cm-1, on the other hand, shows very little change.

Figure 2: ATR spectra of the polymer, 60 mm away from the gate at 0° (red), 45° (black), and 90° (blue).

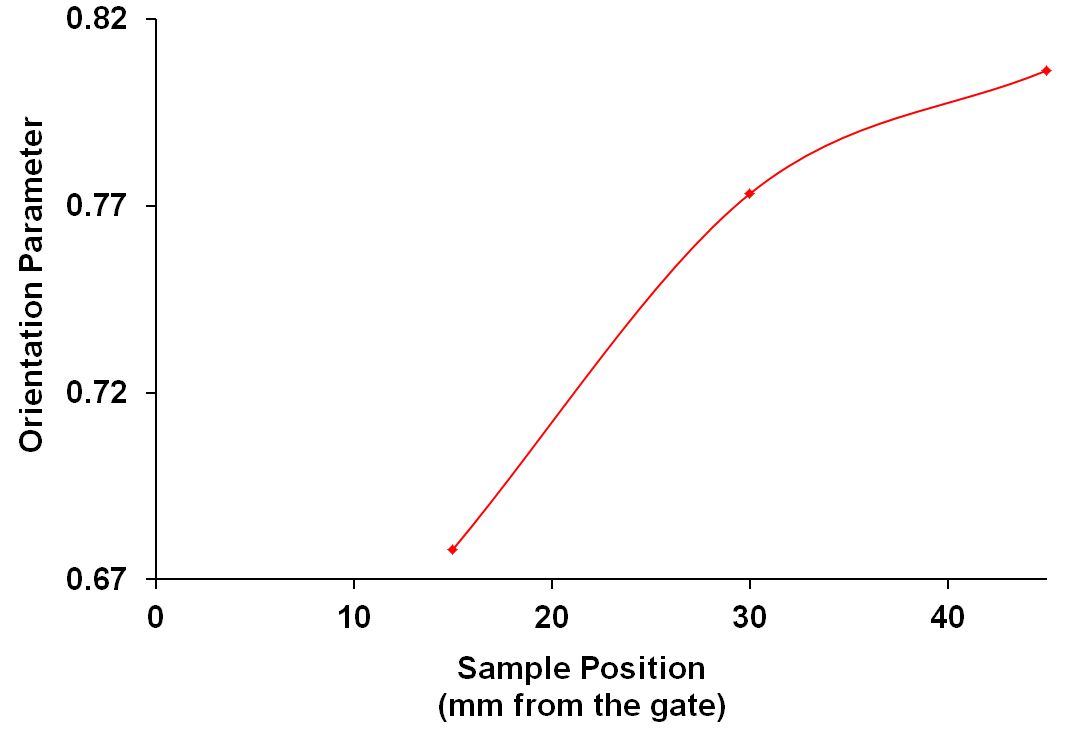

Pirnia and Sung (1) developed a methodology using the dichroic ratios to calculate the orientation function for polymers and determined that the orientation was the highest on the surface, well beyond the gate. The spectra measured here were processed using the methods developed by Pirnia et al. The orientation function (Figure 3) shows the surfaces of the samples become more oriented further from the gate, comparable to the 0.77–0.88 reported.

Figure 3: The orientation function at 1500 cm-1 as a function of distance from the gate.

Conclusion

The orientation of injection-molded polymers can be analyzed by ATR dichromism. Using a variable angle ATR accessory like the Seagull and its ATR rotator, the incident angle can be optimized for a given sample and the orientation axis can be determined.

Reference

1.) A. Pirnia and C.S.P. Sung, Macromol. 21(9), 2699–2706 (1988).

Harrick Scientific Products, Inc.

141 Tompkins Ave., 2nd Floor, Pleasantville, NY 10570

Tel. (800) 248-3847, fax (914) 747-7209

www.harricksci.com

Single Reaction Chamber Microwave Digestion Revolutionizes Elemental Analysis

February 14th 2024The advantages of single reaction chamber (SRC) microwave digestion are presented and exemplified by its application to sample preparation for food, advanced materials, mining and geochemistry, and consumer goods analyses.