SRC Microwave Digestion

Application Notebook

Single reaction chamber (SRC) microwave digestion offers multiple benefits over traditional dry ashing for the sample preparation of heavy crude oils for trace metals analysis. These include increased sample throughput, reduced risk of contamination, more complete digestion and retention of volatile analytes.

The digestion of heavy crude oil samples prior to trace metal analysis by ICP-OES has traditionally been performed by dry ashing in a muffle furnace. The oil is burned off over a burner prior to ashing in a muffle furnace. This process takes several hours and requires continual operator attention. Loss of sample and cross contamination can occur due to foaming and splashing. Additionally, volatile analytes are lost and cannot be measured. While closed vessel microwave digestion offers several advantages over dry ashing, the max sample weight of ~0.2 g is considered too small for resentative analysis. Single reaction chamber (SRC) microwave digestion, however, can digest higher sample weights, enabling microwave digestion to be applied to the sample preparation of heavy oils.

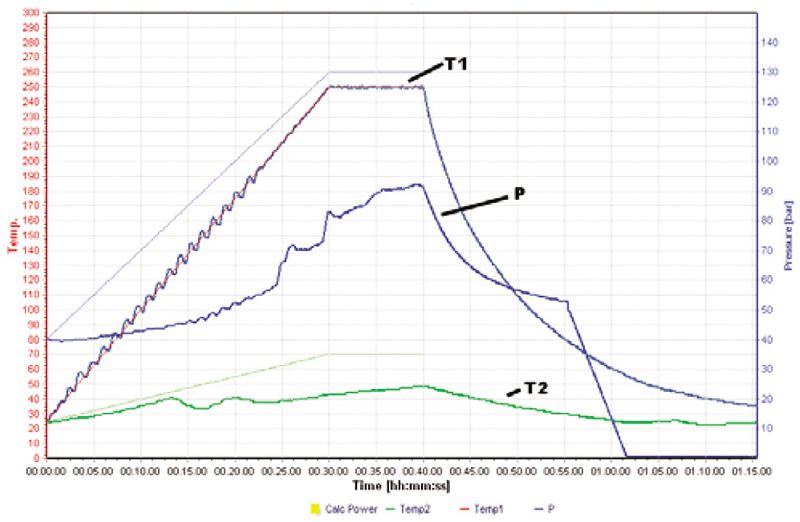

Figure 1: UltraWAVE digestion program with 5 × 0.75 g heavy oil: ramp to 250 °C over 30 min and hold for 10 min. The line T1 shows the actual digestion temperature achieved. The applied microwave power is automatically controlled by the system so the actual digestion temperature precisely follows the programmed temperature profile. The outer temperature of the reaction chamber is also monitored (T2). Note that pressure (P) reached almost 100 bar during the run. This is due to the high weight and high organic content of the samples, which generates NOx and CO2. Pressure was released automatically at 55 min.

Instrumentation

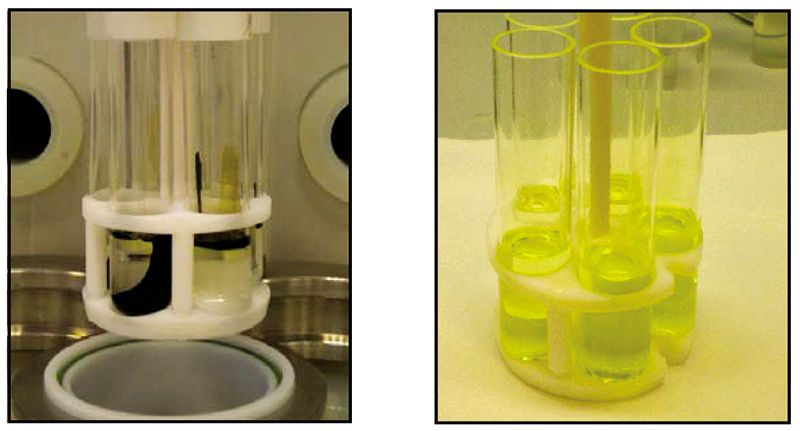

Milestone's new UltraWAVE SRC benchtop digestion system can digest up to five heavy oil samples at a time, max 300 °C and 199 bar pressure. Its high temperature and pressure capability enables the complete digestion of heavy oils, which makes sample introduction to the ICP-OES easier and more routine. The Ultra-WAVE can digest 0.75 g of heavy oil (up to five samples simultaneously)-more than 3x higher sample weight than closed vessel digestion. Samples are simply digested in disposable glass vials: unlike dry ashing, there are no crucibles to clean. The system is fully automated: the sample is weighed into a vial, 10 mL HNO3 added and loaded into the UltraWAVE. Its walk away operation means labor costs are significantly reduced over dry ashing. The reaction chamber is pre-pressurized with N2, which eliminates cross contamination of loss of volatiles.

Figure 2: Sample rack being loaded and samples after digestion.

Conclusion

Sample digestion requires about one hour, including cool down time with the Milestone UltraWAVE. The digestion of heavy oils in the amounts described were sufficient for the application with increased sample throughput and reduced labor costs compared to dry ashing. Risk of contamination and loss of volatile elements is eliminated and the superior digestion quality allows for easier analysis by ICP-OES.

Milestone, Inc.

25 Controls Drive, Shelton, CT 06484

tel. (866) 995-5100, fax (203) 925-4241

Website: www.milestonesci.com