- Spectroscopy-03-01-2015

- Volume 30

- Issue 3

Determining Elemental Impurities in Pharmaceutical Materials: How to Choose the Right Technique

This installment evaluates the application requirements for the determination of 15 elemental impurities in pharmaceutical materials as described in the new United States Pharmacopeia (USP) Chapters and and offers suggestions about which atomic spectroscopic technique might be the most suitable to use.

This installment evaluates the application requirements for the determination of 15 elemental impurities in pharmaceutical materials as described in the new United States Pharmacopeia (USP) Chapters <232> and <233> and offers suggestions about which atomic spectroscopic technique might be the most suitable to use.

Since the introduction of the first commercially available atomic absorption (AA) spectrophotometer in the early 1960s, there has been an increasing demand for better, faster, easier-to-use, and more flexible trace-element instrumentation. A conservative estimate shows that in 2015, the market for atomic spectroscopy instruments will be close to $1 billion in annual revenue - and that doesn't include aftermarket sales and service costs, which could increase this number by an additional $400–500 million. As a result of this growth, we have seen a rapid emergence of more-sophisticated equipment and easier-to-use software. Moreover, with an increase in the number of manufacturers of atomic spectroscopy instrumentation and its sampling accessories, together with the availability of newer techniques like microwave-induced plasma optical emission spectroscopy (MIP-OES) and laser-induced breakdown spectroscopy (LIBS), the choice of which technique to use is often unclear. It also becomes even more complicated when budgetary restrictions allow only one analytical technique to be purchased to solve a particular application problem.

To select the best technique for a particular analytical problem, it is important to understand exactly what the problem is and how it is going to be solved. For example, if the requirement is to monitor copper at percentage levels in a copper plating bath and it is only going to be done once per shift, flame atomic absorption would adequately fill this role. Alternatively, when selecting an instrument to determine 15 elemental impurities in pharmaceutical products according to United States Pharmacopeia (USP) Chapters <232> and <233>, this application is probably better suited for a multielement technique such as inductively coupled plasma–optical emission spectrometry (ICP-OES) or perhaps inductively coupled plasma–mass spectrometry (ICP-MS), depending on the materials being analyzed.

So, when choosing a technique it is important to understand not only the application problem, but also the strengths and weaknesses of the technology being applied to solve the problem. However, there are many overlapping areas between the major atomic spectroscopy techniques, so it is highly likely that for some applications, more than one technique would be suitable. For that reason, it is important to go through a carefully thought out evaluation process when selecting a piece of equipment.

The main intent of this installment is to look at the application requirements for the determination of 15 elemental impurities in pharmaceutical materials as described in the new USP Chapters <232> and <233> (1,2). The goal is to offer some insight as to which might be the most suitable atomic spectroscopic approach, particularly for new users who do not have a strong background or training in the real-world application of these techniques. We will not discuss either the MIP-OES or LIBS techniques in this evaluation. They are both very useful techniques for many sample types and have been described at length in the open literature (3). However, for the purpose of space and clarity, we will be focusing on the four most commonly used atomic spectroscopy techniques: flame atomic absorption (FAA), electrothermal atomization (ETA), ICP-OES, and ICP-MS.

To set the stage, let's first take a brief look at their fundamental principles. Simplified schematics of each of these techniques are shown in Figure 1.

Figure 1: Simplified schematic of AA, ICP-OES, and ICP-MS.

Flame Atomic Absorption

This is predominantly a single-element technique for the analysis of liquid samples that uses a flame to generate ground-state atoms. The sample is aspirated into the flame via a nebulizer and a spray chamber. The ground-state atoms of the sample absorb light of a particular wavelength, either from an element-specific, hollow cathode lamp or a continuum source lamp. The amount of light absorbed is measured by a monochromator (optical system) and detected by a photomultiplier tube or solid-state detector, which converts the photons into an electrical signal. As in all atomic spectroscopy techniques, this signal is used to determine the concentration of that element in the sample, by comparing it to calibration or reference standards.

FAA typically uses a liquid sample flow of about 2–5 mL/min and is capable of handling in excess of 10% total dissolved solids, although for optimum performance it is best to keep the solids down below 2%. For the majority of elements, its detection capability is 1–100 ppb with an analytical range up to 10–1000 ppm, depending on the absorption wavelength used. However, it is not really suitable for the determination of the halogens, nonmetals like carbon, sulfur, and phosphorus, and has very poor detection limits for the refractory, rare earth, and transuranic elements. Sample throughput for 15 elements per sample is typically 10 samples per hour.

Electrothermal Atomization

This is also mainly a single-element technique, although multielement instrumentation is now available. It works on the same principle as FAA, except that the flame is replaced by a small heated tungsten filament or graphite tube. The other major difference is that in ETA, a very small sample (typically, 50 μL) is injected onto the filament or into the tube, and not aspirated via a nebulizer and a spray chamber. Because the ground-state atoms are concentrated in a smaller area, more absorption takes place. The result is that ETA offers detection capability at the 0.01–1 ppb level, with an analytical range up to 10–100 ppb.

The elemental coverage limitations of the technique are similar to the FAA technique. However, because a heated graphite tube is used for atomization in most commercial instruments, it cannot determine the refractory, rare earth, and transuranic elements because they tend to form stable carbides that cannot be readily atomized. One of the added benefits is that ETA can also analyze slurries and some solids because no nebulization process is involved in introducing the sample. This technique is not ideally suited for multielement analysis because it takes 3–4 min to determine one element per sample. As a result, sample throughput for 15 elements is in the order of one sample per hour.

Hydride Generation AA

Hydride generation (HG) is a very useful analytical technique to determine the hydride forming metals, such as As, Bi, Sb, Se, and Te, usually by AA (although detection by either ICP-OES or ICP-MS can also be used). In this technique, the analytes in the sample matrix are first reacted with a very strong reducing agent, such as sodium borohydride, to release their volatile hydrides, which are then swept into a heated quartz tube for atomization. The tube is heated either by a flame or a small oven that creates the ground state atoms of the element of interest and then measures by atomic absorption. When used with ICP-OES or ICP-MS, the volatile hydrides are passed directly in the plasma for excitation or ionization.

By choosing the optimum chemistry, mercury can also be reduced in solution in this way to generate elemental mercury. This is known as the cold vapor (CV) technique. HGAA and CVAA can improve the detection for these elements compared to FAA by up to three orders of magnitude, achieving detection capability of 0.005–0.1 ppb with an analytical range up to 5–100 ppb, depending on the element of interest. It should also be pointed out that dedicated mercury analyzers (some using gold amalgamation techniques), coupled with atomic absorption or atomic fluorescence are capable of better detection limits. Because of the on-line chemistry involved, these techniques are very time-consuming and are normally used in conjunction with FAA, so they will most likely impact the overall sample throughput.

Radial ICP-OES

Radially viewed ICP-OES is a multielement technique that uses a traditional radial (side-view) inductively coupled plasma to excite ground-state atoms to the point where they emit wavelength-specific photons of light that are characteristic of a particular element. The number of photons produced at an element-specific wavelength is measured by high resolution optics and a photon-sensitive device such as a photomultiplier tube or a solid state detector. This emission signal is directly related to the concentration of that element in the sample. The analytical temperature of an ICP is about 6000–7000 K, compared to that of a flame or a graphite furnace, which is typically 2500–3500 K.

For the majority of elements, a radial ICP instrument can achieve detection capability of 0.1–100 ppb with an analytical range up to 10–1000 ppm, depending on the emission wavelength used. The technique can determine a similar number of elements as FAA can, but has the advantage of offering the capability of nonmetals like sulfur and phosphorus, together much better performance for the refractory, rare earth, and transuranic elements. The sample requirement for ICP-OES is approximately 1 mL/min, although lower flow nebulizers are available. Instruments are capable of aspirating samples containing up to 10% total dissolved solids; for optimum performance, the level is usually kept below 2%. ICP-OES is a rapid multielement technique, so sample throughput for 15 elements per sample is in the order of 20 samples an hour.

Axial ICP-OES

The principle of axial ICP-OES is exactly the same as that of radial ICP-OES, except that in axial ICP-OES, the plasma is viewed horizontally (end-on). The benefit is that more photons are seen by the detector, and for this reason detection limits can be as much as an order of magnitude lower, depending on the design of the instrument. The disadvantage is that the working range is also reduced by an order of magnitude. As a result, for the majority of elements, an axial ICP instrument can achieve detection capability of 0.01–10 ppb with an analytical range up to 1–100 ppm, depending on the emission wavelength used. The other disadvantage of viewing axially is that more severe matrix suppression is observed, which means that the total dissolved solids content of the sample needs to be kept much lower. Sample flow requirements are the same as for radial ICP-OES.

Most commercial ICP-OES instruments have both radial and axial capability built in. However, because of the different hardware configurations available, some instruments work by carrying out the analysis either using the radial or the axial view (sequentially). Others can use both the radial and axial view at exactly the same time (simultaneously), which for some applications may be advantageous. Strategic use of both radial and axial view, together with the optimum wavelength selection, can extend the analytical range by 2–3 orders of magnitude. Sample throughput is approximately 20 samples per hour, the same as that of radial ICP-OES.

ICP-MS

The fundamental difference between ICP-OES and ICP-MS is that in ICP-MS, the plasma is not used to generate photons, but to generate positively charged ions. The ions produced are transported and separated by their atomic mass-to-charge ratio using a mass-filtering device such as a quadrupole or a magnetic sector. The generation of such large numbers of positively charged ions allows ICP-MS to achieve detection limits approximately three orders of magnitude lower than ICP-OES, even for the refractory, rare earth, and transuranic elements. As a result, for the majority of elements, an ICP-MS instrument can achieve detection capability of 0.0001–1 ppb with an analytical range up to 0.1–100 ppm, using pulse counting measurement, but can be extended even further up to 100–100,000 ppm by using analog counting techniques. However, it should be emphasized that if such large analyte concentrations are being measured, expectations should be realistic about also carrying out ultratrace determinations of the same element in the same sample run.

The sample requirement for ICP-MS is approximately 1 mL/min, although lower flow nebulizers are available. ICP-MS systems are capable of aspirating samples containing up to 5% total dissolved solids for short periods with the use of specialized sampling accessories. However, because the sample is being aspirated into the mass spectrometer, for optimum performance, matrix components should ideally be kept below 0.2%. This is particularly relevant for laboratories that experience a high sample workload. Sample throughput will be approximately 20 samples per hour for the determination of 15 elements in a sample

.

Comparison Highlights

There is no question that the multielement techniques like ICP-OES and ICP-MS are better suited for the determination of the 15 elements defined in USP Chapters <232>, especially in laboratories that are expected to be carrying out the analysis in a high-throughput, routine environment. If the best detection limits are required, ICP-MS offers the best choice, followed by graphite furnace AA (ETA). Axial ICP-OES offers very good detection limits for most elements, but generally not as good as ETA. Radial ICP-OES and FAA show approximately the same detection limits performance, except for the refractory, rare earth, and the transuranic elements, for which performance is much better with ICP-OES. For mercury and those elements that form volatile hydrides, such as As, Bi, Sb, Se, and Te, the cold vapor or hydride generation techniques offer exceptional detection limits. Figures 2 and 3 as well as Table I show an overview of the detection capability, working analytical range, and sample throughput of the major atomic spectroscopy approaches - three of the metrics most commonly used to select a suitable technique. This information should be considered an approximation and used only for guidance purposes.

Figure 2: Typical atomic spectroscopy detection limit ranges.

It is also worth mentioning that the detection limits of quadrupole-based ICP-MS, when used in conjunction with collision-reaction cell or multiple mass separation-selection devices, is now capable of sub-parts-per-trillion (ppt) detection limits, even for elements such as Fe, K, Ca, Se, As, Cr, Mg, V, and Mn, which traditionally suffer from plasma- and solvent-based polyatomic interference.

Figure 3: Typical atomic spectroscopy analytical working ranges.

This is not meant to be a detailed description of the fundamental principles and comparisons of each technique, but a basic understanding as to how they differ from each other. For a more detailed comparison of the strengths and weaknesses of the major atomic spectroscopy techniques, please see reference 5. Now, let's turn our attention to selecting the best technique based on the demands of the application.

Application Demands

Comparing an instrumental technique based on its performance specifications with simple standards is important, but it bears little relevance to how that instrument is going to be used in a real-world situation. For example, instrument detection limits (IDLs) are important to know, but how are they impacted by the matrix and sample preparation procedure? What are the real-world method detection limits (MDLs) and is the technique capable of quantifying the maximum concentration values expected for this analysis? Also, what kind of precision and accuracy can be expected if you're working close to the limit of quantitation (LOQ) for the overall methodology being used? Additionally, on the sample throughput side, how many samples are expected and at what frequency will they be coming into the laboratory? How much time can be spent on sample preparation and how quickly must they be analyzed? Sometimes the level of interferences from the matrix will have a major impact on the selection process or even the amount or volume of sample available for analysis.

Understanding the demands of an application is therefore of critical importance when a technique is being purchased, and particularly if there is a minimum amount of expertise or experience in house on how best to use it to solve a particular application problem. This could be the likely scenario in a pharmaceutical production laboratory that is being asked to check the elemental impurities of incoming raw materials used to manufacture a drug compound. They will now have to follow the new USP Chapters <232> and <233>, which recommends the use of a plasma-based spectroscopic technique to carry out the analysis . . . or any other atomic spectroscopy technique as long as the validation protocols are met.

The expertise of the operator should never be underestimated. If ICP-MS is being seriously considered, it generally requires an analyst with a higher skill level to develop rugged methodology free of interferences that can eventually be put in the hands of an inexperienced user to operate on a routine basis. This again is a real concern if the technique is being used by novice users who have limited expertise in running analytical instrumentation, which may be the case in the pharmaceutical industry. So, let's take a closer look at the new USP chapters to understand what atomic spectroscopy techniques might best meet the demands of this application.

New USP General Chapters on Elemental Impurities

Although the risk factors for heavy metal impurities in pharmaceutical materials have changed dramatically, standard methods for their testing and control have not changed much for more than 100 years, and as a result, most heavy metals limits had little basis in toxicology. For that reason, one of the most significant standards introduced by the USP in the past decade has been new methodology for determining elemental impurities and contaminants in drug products and dietary supplements. The new methods have been summarized in the United States Pharmacopeia 37–National Formulary 32 (USP-NF) General Chapters <232> and <233> for pharmaceutical products and Chapter <2232> for dietary supplements (4). These three methods will be replacing Chapter <231> (6), which is a 100-year old colorimetric test for heavy metals based on precipitation of the metal sulfide in a sample and comparing it to a lead standard.

These new methods have been going through a review and approval process for a number of years, but by a combination of pushback from the pharmaceutical industry and discussions with other global pharmacopeias, toxicity levels and implementation timelines have been changed a number of times. However, a recent announcement by the USP (7) has indicated that these new chapters will finally be implemented on January 1, 2018, to coincide with the full approval with the International Conference on HarmonizationQ3D Step 4 guidelines, which is expected to be December 16, 2017, for existing pharmaceutical products. (Note: the International Conference on Harmonization [ICH] of Technical Requirements for Registration of Pharmaceuticals for Human Use is an international body that brings together the regulatory authorities and pharmaceutical industry in Europe, Japan, and the United States to discuss scientific and technical aspects of drug registration) (8).

Let's take a closer look at USP Chapters <232> and <233> to get a better understanding of the analytical requirements for this application.

USP General Chapter <232>

Chapter <232> specifies limits for the amount of elemental impurities in drug products, drug substances, active ingredients, and excipients. These impurities may be present naturally, derived from the production catalysts, or introduced inadvertently through the manufacturing process, or they could be environmental contaminants in the pharmaceutical raw materials. When elemental impurities are known to have the potential to be present, compliance to the specified levels is a requirement. Additionally, because of the ubiquitous nature of arsenic, cadmium, lead, and mercury, those four elements at a very minimum must be monitored. The elemental impurity levels in the drug products, unless otherwise specified in an individual drug product monograph, must show compliance with the limits specified and must be made available to the regulatory agency upon request.

A total of 15 elemental impurities (Cd, Pb, As, Hg, In, Os, Pd, Pt, Rh, Ru, Cr, Mo, Ni, V, and Cu) are specified together with their toxicity limits, defined as maximum permitted daily exposure (PDE) levels in micrograms per day for the four major drug delivery categories. The PDE limits, which represent updated levels proposed by USP in an attempt to align itself with ICH guidelines, are shown in Table II. Note: ICH guidelines define impurity levels for an additional nine elements. Of the 15 common elements, the majority of PDE levels are similar in both USP and ICH methods, but some are slightly different, which is the basis of ongoing discussions between the two organizations. For specific details about elemental impurities and their limits, please refer to the cited ICH reference (8). It's also worth pointing out that USP and ICH are going through the alignment process, and until this is finalized, it is difficult to know what the final USP PDE limits will be. For that reason, please refer to the USP elemental impurities web pages (7) for updates.

Speciated Forms

Chapter <232> also addresses speciation, although it does not specify an analytical procedure. Each of the elemental impurities has the potential to be present in differing oxidation states or species. However, arsenic and mercury are of particular concern because of the differing toxicities of their inorganic and organic forms. The arsenic limits are based on the inorganic form, which is the most toxic. Arsenic can be measured using a total-arsenic procedure under the assumption that all arsenic contained in the material under test is in the inorganic form. When the limit is exceeded using a total-arsenic procedure, it should be demonstrated using a suitable procedure to separate the species and to ensure that the inorganic form meets the specification.

The mercury limits are based on the inorganic form because methyl mercury, the most toxic form, is rarely an issue for pharmaceuticals. Therefore, the limit was established assuming that if mercury was present in the drug compound it would exist as the most common inorganic form. However, if there is a known potential for the material to contain methyl mercury (such as drugs, supplements, or compounds derived from fish or kelp), an appropriate speciation procedure is required.

USP General Chapter <233>

Chapter <233> deals with the analytical procedure, including the sample preparation procedure, instrumental method, and validation protocols for measuring the elemental impurities using one of two plasma-based spectrochemical techniques - ICP-OES, ICP-MS, or alternatively any other trace-element technique such as FAA or graphite furnace AA, as long as it meets the data quality objectives of the method defined in the validation protocol section. In addition, before any technique is used, the overall analytical procedure must be confirmed to be appropriate for the instrument being used and the samples being analyzed by meeting the Alternative Procedure Validation protocol (9). The chapter also recommends reading USP General Chapter <730> on plasma spectrochemistry for further guidance (10).

Validation Protocol

Meeting the validation protocol is critical when selecting the best technique for this application because all aspects of the analytical procedures, including the instrumental technique and dissolution process, must be validated and shown to be acceptable, in accordance with the validation protocol described in Chapter <233>. The requirements for the validation of a procedure for elemental impurities is then determined by following a set of quality protocols, which cover a variety of performance tests, including

- Detectability

- Precision

- Specificity

- Accuracy

- Ruggedness

- Limit of quantification

- Linear range

Meeting the performance requirements defined in these tests must be demonstrated experimentally using an appropriate system suitability procedure and reference material. The suitability of the method must be determined by conducting studies with the material under test supplemented or spiked with known concentrations of each target element of interest at the appropriate acceptance limit concentration. It should also be emphasized that the materials under test must be spiked before any sample preparation steps are performed.

Suitability of the Technique

To get a better understanding of the suitability of the technique being used and whether its detection capability is appropriate for the analytical task, it's important to know the PDE limit for each target element, and in particular, what the USP calls the J-value. In Chapter <233>, the J-value is defined as the PDE concentration of the element of interest, appropriately diluted to the working range of the instrument, after completion of the sample preparation procedure to get the sample into solution.

To understand the J-value, let's use Pb as an example. The PDE limit for Pb in an oral medication defined in Chapter <232> is 5 μg/day. Based on a suggested dosage of 10 g of the drug product per day, that is equivalent to 0.5 μg/g Pb. If 2 g of sample is digested or dissolved and made up to 100 mL, that's a 50-fold dilution, which is equivalent to 10 μg/L. So the J-value for Pb in this example is equal to 10 μg/L. (Note: Further sample dilutions can be made if required, based on the technique being used.)

The method then suggests using a calibration made up of two standards: standard 1 = 2.0 J, standard 2 = 0.5 J. So for Pb, this is equivalent to 20 μg/L for standard 1 and 5 μg/L for standard 2.

The suitability of a technique is then determined by measuring the calibration drift and comparing results for standard 1 before and after the analysis of all the sample solutions under test. This calibration drift should be <20% for each target element. However, after the suitability of the technique has been determined, further validation protocols described previously must be carried out to show compliance to the regulatory agency if required.

It should also be pointed out that no specific instrumental parameters are suggested in this section, but only to perform the analysis according to the manufacturer's suggested conditions and to calculate and report results based on the original sample size. However, it does say that appropriate measures must be taken to correct for interferences, such as matrix-induced wavelength overlaps in ICP-OES and argon-based polyatomic interference with ICP-MS.

So with this information, let's take as an example the oral drug delivery method and calculate the J-values for each elemental impurity and compare them with the limits of quantitation (LOQ) for each technique to give us an assessment of their suitability. For this analytical scenario, we'll take the LOQ for the method as 10× the IDL. These LOQs were calculated by taking the average of published IDLs from three instrument vendors' application material and multiplying them by 10 to get an approximation of the LOQ. In practice, a method LOQ is typically determined by processing the matrix blank through the entire sample preparation procedure and taking 10 replicate measurements. The method LOQ, sometimes referred to as the method detection limit (MDL), is then calculated as 3× the standard deviation of these 10 measurements.

To make this comparison valid, the sample weight was adjusted for each technique, based on the detection limit and analytical working range. For AA and ICP-OES, we used a sample dilution of 2 g/100 mL, whereas for ICP-MS we used 0.2 g/100 mL. AA and ICP-OES could definitely use larger sample weights, but for high-throughput routine analysis, we are probably at the optimum dilution for ICP-MS. Tables III, IV, and V show the comparison of AA (FAA and ETA), ICP-OES, and ICP-MS, respectively. The important data to consider are in the final column, labeled "Factor Improvement," which is the J-value divided by the LOQ. Generally speaking, the higher this number, the more suitable the technique is.

Discussion

It should be emphasized again that LOQ in these examples is just a guideline as to the real-world detection capability of the technique for this method. However, it does offer a very good approximation as to whether the technique is suitable based on the factor improvement number compared to the J-values for each elemental impurity. Clearly, if this improvement number is close to or less than one, as it is with the majority of elements by FAA, the technique is just not going to be suitable, particularly for the "big four" heavy metals, which are the most critical. On the other hand, ETA would be suitable for the majority of the impurities (including the heavy metals), except for a few of the catalyst-based elements, which are not ideally suited to the technique. However, the ETA technique is very time-consuming and labor intensive, so it probably wouldn't be a practical solution in a high-throughput pharmaceutical production laboratory.

Table IV shows that axial ICP-OES offers some possibilities for monitoring oral drugs because the vast majority of the improvement factors are higher than one. These numbers could be further improved, especially for the heavy metals, by using a much higher sample weight in the sample preparation procedure without compromising the method. (Note: Because most commercial ICP-OES instrumentation offers both axial and radial capability, it was felt that the axial performance was the most appropriate for this comparison.)

However, it can be seen in Table V that ICP-MS shows significant improvement factors for all impurities, which are not offered by any other technique. Even for the four heavy metals, there appears to be ample improvement to monitor them with good accuracy and precision. The added benefit of using ICP-MS is that it would also be suitable for the other methods of pharmaceutical delivery, such as intravenous feeding, injection, or inhalation, where the PDE levels are typically an order of magnitude lower. Additionally, if arsenic or mercury levels were found to be higher than the PDE levels, it would be relatively straightforward to couple ICP-MS with high performance liquid chromatography (HPLC) to monitor the speciated forms of these elements.

Final Thoughts

There are many factors to consider when selecting a trace-element technique that is the most suited to the demands of your application. Sometimes, one technique stands out as being the clear choice, whereas other times it is not quite so obvious. And, as is true with many applications, more than one technique is often suitable. However, the current methodology described in the new USP Chapters <232>, <233>, and <2232> presents unique challenges, not only from a perspective of performance capability, but also because of the validation protocols that have to be met to show suitability of the technique for the analytical procedure being used. From a practical perspective, there is no question that to meet all of the PDE limits in all pharmaceutical delivery methods, ICP-MS is probably the most appropriate technique. However, for oral delivery medications, especially those that can be easily brought into solution with a suitable aqueous or organic solvent, axial ICP-OES could offer a less costly approach. Also, if the sample workload requirements are not so demanding, ETA could provide a solution.

It will be interesting to eventually see how USP limits and methodology will be aligned with ICH directives, but the recent announcement delaying implementation should not discourage global pharmaceutical and nutraceutical manufacturers to have the appropriate analytical capability in place as soon as possible to show compliance to regulators that their products are free from elemental impurities and contaminants. This is reinforced by the statement in the frequently asked questions that went along with the most recent USP announcement (7): "Given that General Chapters <232> and <2232> provide significant improvements over existing approaches in the control of elemental impurities, USP encourages users to implement the new methods as soon as reasonably possible." So it's clear, the USP takeaway message is that even though full implementation has been delayed to coincide with the completion of the ICHQ3D approval process, the pharmaceutical industry should continue to move forward with the adoption of the new methodology.

References

(1) General Chapter <232> "Elemental Impurities in Pharmaceutical Materials – Limits," in second supplement to USP37– NF32, 2014 (United States Pharmacopeial Convention, Rockville, Maryland).

(2) General Chapter <233> "Elemental Impurities in Pharmaceutical Materials – Procedures," in second supplement to USP37– NF32, 2014 (United States Pharmacopeial Convention, Rockville, Maryland).

(3) R.J. Thomas, Spectroscopy3(29), 42–51 (2014).

(4) General Chapter <2232> "Elemental Contamination in Dietary Supplement," in second supplement to USP37– NF32, 2014 (United States Pharmacopeial Convention, Rockville, Maryland).

(5) R.J. Thomas, How to Select an ICP-MS: Some Important Considerations, Practical Guide to ICP-MS: A Tutorial for Beginners, 3rd Edition, (CRC Press, Boca Raton, Florida, 2013) ISBN 978-1-4665-5543-3.

(6) General Chapter <231> "Heavy Metals Test" in second supplement to USP37– NF32, 2014 (United States Pharmacopeial Convention, Rockville, Maryland).

(7) United States Pharmacopeia Update Communication, January 14, 2015:

(8) International Conference on Harmonization, ICH Q3D Step 4 - Guideline for Elemental Impurities (ICH, Geneva, Switzerland, 2014).

(9) General Chapter <1225> "Validation of Compendial Procedures" in second supplement to USP37– NF32, 2014 (United States Pharmacopeial Convention, Rockville, Maryland).

(10) General Chapter <730> "Guidelines on Plasma Spectrochemistry" in second supplement to USP37– NF32, 2014 (United States Pharmacopeial Convention, Rockville, Maryland).

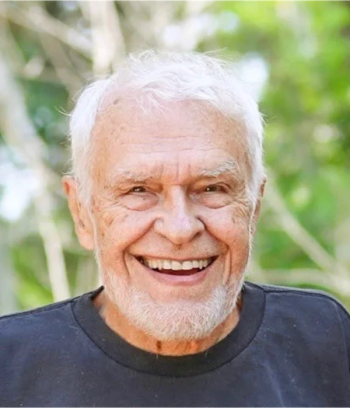

Robert Thomas has more than 40 years of experience in trace-element analysis. He is the principal of his own freelance writing and scientific consulting company, Scientific Solutions, based in Gaithersburg, Maryland.

Robert Thomas

Articles in this issue

almost 11 years ago

2015 Salary Survey: Modest Gains, but Not for Everyonealmost 11 years ago

App of the Month: 1HCSCalmost 11 years ago

Vol 30 No 3 Spectroscopy March 2015 Regular Issue PDFNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.