Article

Application Notebook

Application Notebook

Modeling and Monitoring of Time-Dependent Processes with Spectroscopic Techniques

Author(s):

Spectroscopic techniques have a long history as quantitative methods for on-line and at-line use in a wide range of industries, where, in many cases, they are more accurate than the reference methods. These processes are typically continuous, but time-depending processes such as batch processes are widely used in many industries.

Spectroscopic techniques have a long history as quantitative methods for on-line and at-line use in a wide range of industries, where, in many cases, they are more accurate than the reference methods. These processes are typically continuous, but time-depending processes such as batch processes are widely used in many industries. Typically, raw materials are combined in a suitable batch vessel before chemical, physical, or biological transformation takes place, resulting in the end product or a desired state of the process.

In many cases the control of the batch process is recipe driven and the operations are not adjusted to accommodate raw material variation and changes in uncontrollable factors. The best possible end product quality is achieved by adapting batch operations according to any detectable changes during processing. Optimal run settings and the ability to control them within a design space leads to reduced rework and rejects, and improved end product quality.

One of the unit operations in pharmaceutical industry is drying of granulate in tablet manufacturing. The main challenge is to decide when the optimal moisture content has been reached, for which in-line spectroscopy is an ideal technique. In this specific application NIR spectra were collected during fluid bed drying of a granular intermediate. The spectra consisted of a total of 1093 wavelengths in the range 9090–4484 cm-1 (1100–2230 nm) at 4 cm-1 resolution. Due to the noisy nature of Fourier transform (FT) NIR (particularly at such high resolution) the spectra were smoothed with an 11-point moving average before applying a standard normal variate (SNV) to reduce the systematic baseline effects in the spectra.

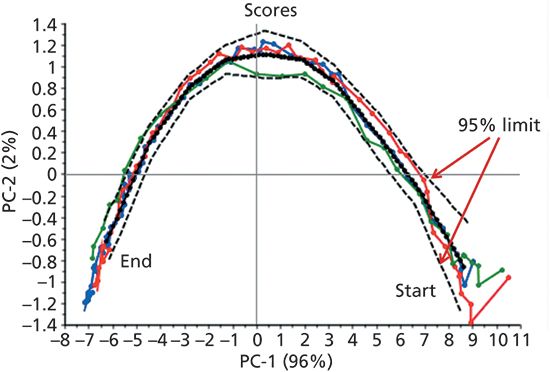

Multivariate methods are normally applied to the spectral data as they capture the information in terms of underlying variation which often has a direct chemical or biological interpretation. CAMO Software has developed a new methodology for where the batch processes are modeled in relative time, thus handling different sampling rates and non-linear progression of the batches directly. One visualization from this model is a plot of the batch trajectory with confidence intervals. Figure 1 shows how the batches change over time, ending up with the dry product.

Figure 1: Batch trajectory with confidence intervals.

The same principle can be applied for other common industrial processes; for example, Raman spectroscopy has a huge potential as an in-line technique for bioprocesses like fermentation. Another possible use is in medical diagnostics where this new approach is suited for following patients over time and monitor the effects of treatment.

CAMO Software

One Woodbridge Ctr., Suite 319, Woodbridge, NJ 07095

tel. (732) 726-9200

Website: www.camo.com

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.