- Special Issues-06-01-2009

- Volume 0

- Issue 0

Analysis of Multicomponent Polymer Blends with Confocal Raman Imaging and Atomic Force Microscopy

Polymer blends are designed to address the needs of different industries, and in many cases the relationship between structure, morphology, and material properties is indispensable for optimization of material design.

The morphology and phase separation process within thin films of polymer blends has been studied with confocal Raman atomic force microscopy (AFM). Confocal Raman microscopy, which provides information about the chemical distribution of the blend components, combined with a powerful software package, showed that polystyrene and ethyl-hexyl-acrylate form well-separated domains. Both polymers form an interface with the glass substrate during the de-wetting process. Styrene-butadiene-rubber is formed on top of the acrylate phase. The fine structure of each blend component was studied with AFM.

Polymer blends are designed to address the needs of different industries, and in many cases the relationship between structure, morphology, and material properties is indispensable for optimization of material design. Since the beginning of the plastics industry, it has been recognized that blending yields materials with property profiles superior to the features of the individual components. A polymer blend is a macroscopically homogeneous mixture of two or more different species of polymer that combines the useful properties of all the constituents. New polymer blends are constantly being developed and characterized. The main parameters that influence the properties of a blend are the interface and the morphology. The morphology of a polymer blend indicates the size, shape, and spatial distribution of the component phases with respect to each other. The properties such as mechanical, optical, rheological, dielectrical, and barrier properties of polymer blends are strongly influenced by the type and fineness of the phase structure. A large variety of analytical methods are used to characterize the morphology of polymer blends. Raman spectroscopy is one of the standard characterization techniques used to determine the chemical composition of a polymer (1–3).

Raman imaging contributes to the analysis of multicomponent polymer systems by visualizing the distribution of individual components based on the unique Raman spectra for different polymeric materials. Domains of different components in polymer blends are formed during phase separation and are typically a few hundred nanometers in size. These domains can be visualized with a confocal Raman microscope with a resolution down to 200 nm (4–6). In the past few years, new instrument developments have allowed the recording of a complete Raman spectrum in less than one millisecond from a very small sample volume; thus the acquisition time for two-dimensional (2D) arrays of tens of thousands of Raman spectra was reduced to a few minutes (7–9). Powerful software packages, which allow a fast evaluation of such 2D spectral arrays, make Raman imaging indispensable for the morphological characterization of polymer blends.

By integrating an atomic force microscope with the confocal Raman microscope, microphase separation patterns with spherical, cylindrical, lamellar, or micellar morphology with structure sizes in the nanometer regime can be analyzed (10,11).

In the following discussion, different thin films of polymer blends composed of immiscible polymers are investigated using a combined confocal Raman atomic force microscope.

Experimental

Three different thin films of polymer blends with a thickness of less than 100 nm were prepared by spin coating (2000 rpm) of solutions containing the polymers on a clean glass cover slide:

- polystyrene (PS)–ethyl-hexyl-acrylate (EHA), which at room temperature consists of the glassy PS and the rubbery EHA;

- ethyl-hexyl-acrylate (EHA)–styrene-butadiene-rubber (SBR), which is in the rubbery state at room temperature;

- polystyrene (PS)–ethyl-hexyl-acrylate (EHA)–styrene-butadiene-rubber (SBR).

The alpha300 RA microscope (WITec GmbH, Ulm, Germany), which combines confocal Raman microscopy with atomic force microscopy (AFM), was used to perform the experiments (12). For confocal Raman measurements, the alpha300 RA was equipped with a frequency doubled NdYAG laser (λ = 532 nm) and a 100× (NA = 0.9) air objective.

All AFM measurements were performed in AC mode using ArrowFM cantilever (NanoWorld AG, Neuchâtel,, Switzerland).

Results and Discussion

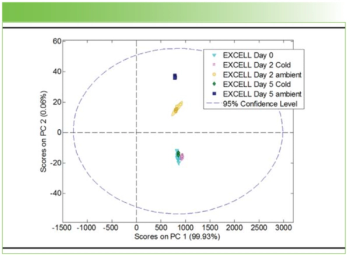

The thin films were first imaged in Raman spectral imaging mode. In this mode, a complete Raman spectrum is recorded at every image pixel, leading to a 2D array of Raman spectra. These were analyzed using the advanced data analysis features of the WITec Project Plus software. The first function applied was cluster analysis. During this procedure the software automatically identifies similar spectra and classifies them into a user-defined number of clusters. Each cluster is represented by an average spectrum and a map that shows the spatial distribution of these similar spectra. This technique is very powerful for determining the number of components in a certain image. It does not require any a priori knowledge about the sample; the user only has to guess the number of components he expects in the sample.

Figure 1: WITec Project Cluster Analysis software showing (a) the cluster tree and (b) the resulting spectra from the analysis of a 2D spectral array recorded from the polymer blend PS-EHA.

For the sample consisting of PS and EHA one would expect only two components, but to demonstrate the effect, three clusters are chosen. Figure 1 shows the result of such a cluster analysis performed on a Raman spectral image data set acquired on the polymer blend PS-EHA. An area of 20 μm ×20 μm was scanned and 200 × 200 complete Raman spectra were acquired with an integration time of 0.03 s/spectrum. Figure 1a shows the color-coded spatial distributions of the three identified clusters (species). Blue denotes the area in which PS is present and green shows the areas allocated to EHA. The third cluster, shown in gray, corresponds to the border between PS and EHA, because all spectra at these borders show the same amount of PS and EHA and are therefore also similar. This indicates that only these two materials are present in the sample and a higher number of clusters is not required. The average spectra for each cluster are shown in Figure 1b. All spectra show a background at wavenumbers below 1500 cm–1, indicating that the spectra from the cluster analysis are not the pure spectra of PS and EHA, but a mixture of substrate and polymer. Therefore, the confocal Raman microscope was focused into the bulk of the glass substrate and a pure Raman spectrum of glass was acquired (Figure 2). To obtain the pure spectra of PS and EHA from this data set, the graph demixer function of the software was used to subtract a weighted glass spectrum from the average spectra. Figure 2 shows the Raman spectra of PS and EHA before (dashed line) and after (solid line) weighted subtraction of the glass spectrum from the spectra calculated in the cluster analysis (compare also with Figure 1b) (2).

Figure 2: Unique Raman spectra of analyzed polymers (full line) and Raman spectra evaluated with the cluster analysis software from 2D spectral arrays recorded from thin films of polymer blends.

The other two polymer blends studied also showed mixed spectra of polymer and glass, indicating that the film thickness of all analyzed blends was well below the z-resolution of the confocal microscope (which was about 1 μm for the NA = 0.9 objective used).

The result of the cluster analysis from the polymer blend EHA-SBR also revealed the presence of two well-defined domains on the sample, one corresponding to the EHA phase and the other to a polymer with the spectrum presented dashed orange in Figure 2. This spectrum, however, also contains all spectral features of EHA and therefore is not a pure SBR phase. After correcting for the glass background by a weighted subtraction of the glass spectrum, a pure EHA spectrum was obtained and was used to obtain a pure SBR spectrum by a subsequent weighted subtraction (red spectrum in Figure 2) (2,10).

The cluster analysis and graph demixer function in these samples were used successfully to determine the pure Raman spectra of the components in the polymer blends. On the other hand, the cluster analysis does not give information about the amount of the different components in a mixture. For this, a basis analysis was performed, with the pure spectra as a basis. In the basis analysis software procedure, each measured spectrum of the 2-D spectral array is fitted by a linear combination of basis spectra Sk using the least squares method (10). The resulting weight factor is proportional to the quantity of the material and is displayed as intensity in the corresponding Raman image.

Figure 3a shows the color-coded Raman image of the polymer blend PS-EHA. This image was obtained after overlaying the resulting images of PS and EHA from the basis analysis and assigning each polymer its color from the corresponding spectrum (Figure 2). The two polymer phases PS and EHA do not show any overlap in the Raman image (Figure 3a), proving that, within the resolution limit of the confocal Raman microscope, the two phases are well separated and form an interface with each other and the glass substrate. The thickness of this polymer film is only 70 nm, but enough to study the phase separation process using Raman imaging within such small sample volumes (11). High-resolution AFM AC mode images were recorded from the same sample on a smaller scan area of 5 μm × 5 μm. The topography image, shown in Figure 3b, reveals elevated circular islands with diameters in the range from 50 nm to 2 μm, which can be associated to the PS islands found in the Raman image (Figure 3a). The simultaneously recorded phase image (shown in Figure 3c) reveals the presence of a fine structure within the EHA phase, which cannot be resolved with confocal microscopy.

Figure 3: Confocal Raman AFM images of the polymer blend PS-EHA: (a) color-coded Raman image, (b) high-resolution AFM topography image, and (c) simultaneously recorded AFM phase image.

The phase separation within the polymer blend of EHA-SBR is shown in Figure 4a. For this image a sample area of 15 μm × 15 μm was scanned and 150 × 150 Raman spectra were recorded with an integration time of 0.1 s/spectrum. The Raman spectra as obtained from the cluster analysis correspond to the dashed green and dashed orange spectra in Figure 2. Basis analysis of the pure components and overlaying the two images reveals that there is no pure SBR in this blend anymore; the orange area is a mixture of EHA and SBR (Figure 4a). To obtain a more detailed insight into the phase separation process in this blend, high-resolution AFM imaging was employed. Figure 4b shows the topography and Figure 4c the simultaneously recorded phase image of this blend. The topography reveals an elevated netlike structure. These elevated structures correspond to the mixed phase recorded in the Raman images (Figure 4a). The phase image reveals that the background structure corresponds to the fine structure of EHA when wetting the glass substrate (Figure 3c). Figure 4d is a close-up of the phase image of Figure 4b and reveals the fine structure of SBR (10), indicating that in this blend EHA is wetting the glass substrate and SBR is formed on top of the EHA layer.

Figure 4: Confocal Raman AFM images of the polymer blend EHA-SBR: (a) color-coded Raman image, (b) high-resolution AFM topography image, (c) simultaneously recorded AFM phase image, and (d) high-resolution phase image of the gray insert.

The Raman image of the three-component thin film PS-EHA-SBR is shown in Figure 5a. An area of 20 μm × 20 μm was scanned in Raman spectral imaging by acquiring 128 × 128 Raman spectra with an integration time of 0.1 s/spectrum. In this image, the blue color shows the distribution of PS while the green areas consist of pure EHA. Yellow denotes a mixed phase of EHA and SBR, while the red areas are pure SBR. This image confirms the previously observed phase separation process: PS, the polymer in the glassy state at room temperature, and EHA are wetting the glass substrate, whereas the SBR is formed on top of the EHA phase. High-resolution AFM images recorded on this blend show that PS is forming a topographically elevated ropelike structure (Figure 5b), surrounded by SBR and EHA. The simultaneously recorded phase image (Figure 5c) reveals the fine structures of EHA and SBR.

Figure 5: Confocal Raman AFM images of the polymer blend PS-EHA-SBR: (a) color-coded Raman image, (b) high-resolution AFM topography image, and (c) simultaneously recorded AFM phase image.

Conclusions

The combination of a confocal Raman microscope with AFM was used for the characterization of polymer blends. Raman spectroscopy allows the identification of chemically different materials. In combination with a confocal microscope, the distribution of various polymer phases within the films can be determined. Although the analyzed films have been very thin (< 100 nm), the sensitivity of the confocal Raman microscope was still high enough to identify the chemical composition of the films with short integration times of 30–100 ms/spectrum.

The analysis of the Raman spectral images obtained from the blended films shows that there is a clear phase separation of PS and EHA, indicating that these two polymers do not mix and have formed an interface with the glass substrate while de-wetting. In the polymer blends consisting of EHA and SBR, an overlap of the two spectra was observed, indicating that these two phases are formed on top of each other.

AFM images reveal the topographic structure of polymer films with a resolution down to a few nanometers. The high-resolution AFM phase images allow the identification of the chain microstructure of EHA and SBR, leading to a complete description of the phase separation process of the polymer blend EHA-SBR.

The combination of AFM and confocal Raman microscopy in a single instrument allows the nondestructive characterization of heterogeneous materials. In combination with powerful software, chemical identification of sample volumes of only 0.02 μm3 becomes available at very short integration times per spectrum.

U. Schmidt, W. Ibach, H. Fischer, and O. Hollricher are with WITec GmbH, Ulm, Germany (

References

(1) H.W. Siesler and K. Holland-Moritz, Infrared and Raman Spectroscopy of Polymers (Marcel Dekker, New York, 1990).

(2) H. Kupsov and G. N. Zhizhin, Handbook of Fourier Transform Raman and Infrared Spectra of Polymers (Elsevier, Amsterdam, 1998).

(3) G. Socrates, Infrared and Raman Characteristic Group Frequencies (Wiley, Chichester, UK, 2001).

(4) T. Wilson, Confocal Microscopy (Academic Press, London, 1990).

(5) U. Schmidt, A. Jauss, W. Ibach, and O. Hollricher, Microscopy Today, 13, 30, (2005).

(6) O. Hollricher, W. Ibach, A. Jauss, and U. Schmidt, FutureFab Intl, 21 (2006).

(7) O. Hollricher, OE Magazine, Nov. (2003).

(8) T. Dieing and O. Hollricher, Vib. Spectrosc. 48, 22 (2008).

(9) Ultra-fast Confocal Raman Imaging, Application Note,

(10) U. Schmidt, S. Hild, and O. Hollricher, Macromol. Symp. 230, 133 (2005).

(11) U. Schmidt, W. Ibach, J. Mueller, and O. Hollricher, SPIEProc. 6616 Pt. 1, 66160E-1, 2007.

(12) Control and data evaluation software for confocal Raman and scanning probe microscopy,

Articles in this issue

over 16 years ago

Combining Raman Spectroscopy and Differential Scanning CalorimetryNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.