- Spectroscopy-04-01-2015

- Volume 30

- Issue 4

Differentiation of Inks Used for Seals by Confocal Raman Microscopy and Fourier Transform Infrared Microscopy

The analysis of seals, mostly via the ink types, can provide evidence to authenticate the related documents and can play a key role in legal cases. In the present study, a method to discriminate red seal inks using Raman microscopy and Fourier transform infrared (FT-IR) spectroscopy was developed.

Volume 30 Number 4 Pages 36-43

The analysis of seals, mostly via the ink types, can provide evidence to authenticate the related documents and can play a key role in legal cases. In the present study, a method to discriminate red seal inks using Raman microscopy and Fourier transform infrared (FT-IR) spectroscopy was developed. The results showed that the developed Raman method was powerful, sensitive, and rapid, and can be used to directly differentiate the red inks with paper substrates; thus, this method would be helpful for ink analysis in the forensic, drawing, and cultural heritage fields.

Hand signatures are popularly used to prove identity in the west and seals are used in the east, especially in eastern Asia, such as China, Japan, and Korea. The seal is a cultural heritage in Asian counties that has represented identity and credentials since a long time ago. The first record of a seal in China can be traced to 554 B.C. (1). Almost all of the official documents, formal commercial contracts, and other items requiring acknowledgement or authority must be certificated by seals in China and many other Asian countries. Seals symbolize statutory powers of the governments, organizations, enterprises, and institutes. Nowadays, seals are still widely applied to various aspects of social life, such as contracts, checks, wills, and artworks. Forgery of seals will be punished by imprisonment for several years in China, but there are still numerous cases relating to the forgery of seals every year. Therefore, it is necessary to identify genuine and fake seals and seal ink analysis can play a role therein. There are three significant problems in seal ink analysis: the characterization and differentiation of inks, the sequencing of intersecting lines (2,3), and dating of inks in documents (4). Among these three problems, the most basic problem is the first one. Solving this problem can provide important information to confirm the authenticity of documents and archaeological artworks.

Many techniques including thin-layer chromatography (TLC) (5), gas chromatography (GC), liquid chromatography (LC), and mass spectrometry (MS) (6–10) have been used to classify the samples. These methods proved to be accurate and effective. However, most of these commonly used methods are time-consuming and destructive to samples. In addition, the seal ink contains binders, fillings, and pigments; the binders are polymers and the fillings and some pigments are inorganic compounds, which are difficult to analyze using the chromatographic methods. Wang and colleagues (11) developed a nondestructive laser desorption ionization mass spectrometry method that successfully classified 38 red ink entries into seven groups. The method can effectively identify the pigments used in the inks, but it cannot analyze the polymers, additives, and inorganic pigments. Because of the limitation in sample quantity in their study, the distribution of different types was not discussed further.

Spectral methods, especially infrared (IR) and Raman spectroscopy, can cover the shortages of the chromatographic and MS methods. They are fast, accurate, nondestructive, and suitable for both organic and inorganic substance analysis. The binders, fillings, and pigments can be easily analyzed using IR spectroscopy. There have been many studies on seal inks using IR methods (12–16), and the results showed that IR can be a valuable nondestructive tool. The biggest drawback of Fourier transform infrared (FT-IR) spectroscopy in ink sample analysis is the interference from paper. Most FT-IR studies have focused on pure inks on slides, which are not available in real cases.

Raman spectroscopy can supply extra molecule vibration information. It has been successfully used in pigment analysis (17–19) and can effectively avoid the paper interference (20), which makes it more applicable than FT-IR in real cases. Thus, in this study Raman microscopy was tentatively used to examine the ink samples. The indicative peaks were specifically assigned, classified, and summarized to discriminate them. FT-IR on-slide analysis was also used to verify the Raman results.

Materials and Methods

A total of 110 red seal ink samples from 37 brands were randomly collected from 10 Chinese provinces. Sample information is listed in Table I. Reagents and standards were analytical grade. A Renishaw inVia confocal Raman microscope system containing a charge-coupled device (CCD) detector was used to collect Raman spectra with the laser emitting at 785 nm. The laser wavelength was chosen for emission at 1–100% power, depending on the proper energy to get signals strong enough and protect the samples from burning. Crystal silicon with a fixed peak position at 520 cm-1 was used to calibrate the Raman shifts before sample analysis. The spectra were collected in WIRE3 workstation software (Renishaw) in extensive mode ranging from 100 cm-1 to 2000 cm-1. Every spectrum was obtained by three accumulations to enhance the signal-to-noise ratio. Multiple measurements (n ≥ 3) were conducted in different regions of the same sample to assess the variation.

A Spectrum Nicolet iN10 system from Thermo Fisher Scientific with a diamond anvil cell and an MCT detector was used for IR observation. Spectra 5.01 workstation software from PerkinElmer was used for data processing. Ink samples were placed in the diamond anvil cells, pressed into thin film, and subjected to IR analysis. The background was subtracted for every measurement. Spectra were collected in high resolution in transmission mode (scan times 22 s, resolution 4 cm-1/s, and number of scans 64). Triplicate tests were performed at different sites for every sample.

Results and Discussion

Raman Analysis

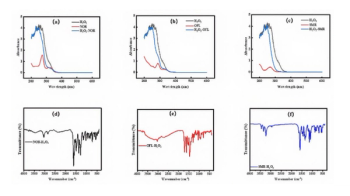

All samples were analyzed with Raman microscopy and their spectra were compared to obtain the differences therein. The 110 samples were thus classified into 18 groups. The typical spectrum of each group is illustrated in Figure 1. Each spectrum was characteristic of the peak positions and intensities, which can be used to discriminate one group from the others. The identified components and the detected rates of the 18 groups as well as the samples included are listed in Table I. Scarlet powder and bronze red C were the pigments most frequently detected in the seal inks. The former was detected in groups 3, 4, 15, and 17 with the total detected rate of 36.4% in 110 samples and the latter was detected in groups 2 and 12 with the rate of 31.8%. PbCrO4 existed in groups 15, 17, and 18 (10.0%); here, the PbCrO4 that we identified could possibly be PbMoO4 since these two substances have similar peak positions and they were not further discriminated in the present study. HgS was detected in groups 15 and 18 (8.2%), Fe2O3 was detected in groups 12 and 16 (5.5%), rhodamine B was detected in group 13 (2.7%), and fast red was detected in group 10 (3.6%). There were still some groups with no typical components identified (groups 1, 5, 6, 7, 8, 9, 11, and 14). The Raman analysis results of bronze red C, scarlet powder, and the fast red coincided well with the recently published studies (11). PbCrO4, HgS, and rhodamine B in ink samples were identified using the Raman method for the first time, to our best knowledge.

Figure 1: Comparison of Raman spectra in different groups: (a) 1–6, (b) 7–12, (c) 13–18.

The most frequently detected pigments in the present study, bronze red C and pigment scarlet powder, are widely used in daily life. Bronze red C is a kind of light-resistant, heat-resistant, and colorfast golden powder. It is insoluble in water, alcohol, or paraffin, and is used in printing inks, stationeries, and coloring PVC or rubber products. Pigment scarlet powder (P.R.21) is a red azo pigment, which is usually used in paints, inks, leather, plastic, rubber, latex products, building materials, stationeries, and cosmetics. The chemical structures and the standard Raman spectra of the two compounds are shown in Figure 2.

Figure 2: Two pigments detected with the highest frequency: (a) Bronze red C, (b) scarlet powder.

The main peaks of the Raman spectrum of the seal ink containing bronze red C were observed at 1599 cm-1 (m), 1553 cm-1 (s), 1482 cm-1 (s), 1451 cm-1 (m), 1401 cm-1 (vs), 1334 cm-1 (m), 1260 cm-1 (w), 1236 cm-1 (s), 1198 cm-1 (m), 1095 cm-1 (m), 986 cm-1 (m), 717 cm-1 (m), 629 cm-1 (m), 610 cm-1 (m), 434 cm-1 (m), 337 cm-1 (m), and 308 cm-1 (m) (Figure 2). The peak at 1599 cm-1 represented the benzene stretching; 1482 cm-1 represented the CCH bending in the benzene ring and C=O stretching; 1401 cm-1 represented the stretching of the naphthalene ring; 1334 cm-1 represented the C-C stretching, N-N, or C-N stretching; and 624 cm-1 represented the C-Cl stretching. The absorption at 986 cm-1 was from the symmetric stretching of SO42-; 629 cm-1 and 610 cm-1 from SO42- out-plane bending; and 434 cm-1 and 420 cm-1 from SO42- in-plane bending. The peak of the symmetric stretching of SO42-in many sulfates appeared at about 990 cm-1, for example, Na2SO4, 994 cm-1. Absorption at 986 cm-1 was indicative of BaSO4 and can be used to identify the pigments containing BaSO4. In summary, the peaks near 1550 cm-1, 1095 cm-1 (m), 629 cm-1 (m), and 610 cm-1 (m) were characteristic and can be used in the identification of bronze red C.

Pigment scarlet powder main peaks appeared at 1595 cm-1 (s), 1547 cm-1 (m), 1493 cm-1 (s), 1360 cm-1 (vs), 1281 cm-1 (w), 1235 cm-1 (w), 1160 cm-1 (s), 998 cm-1 (m), 959 cm-1 (m), 775 cm-1 (m), 732 cm-1 (w), 519 cm-1 (s), and 485 cm-1 (s) (Figure 2). The peaks at 1595 cm-1 and 1493 cm-1 should be assigned to benzene ring vibration; 1546 cm-1, 1360 cm-1, 1283 cm-1, and 1234 cm-1 should be assigned to the frequency of N-H bending and C-N stretching; 1160 cm-1 should be assigned to C-C stretching; 998 cm-1 should be assigned to benzene skeleton stretching; 958 cm-1 should be assigned to the C-C=O stretching; 519 cm-1 and 485 cm-1 should be assigned to C-C=O bending and N-C=O bending. Overall, the indicative peaks at 1595 cm-1 (s), 1547 cm-1 (m), and 1493 cm-1 (s) can be used to discriminate pigment scarlet powder from other the pigments.

PbCrO4, Fe2O3, and HgS were detected in some ink samples. The peaks at 824–838 cm-1 (m-w), 338 cm-1 (w), and 130 cm-1 (w) indicated the existence of PbCrO4; the peak at 838 cm-1 came from the Cr-O stretching vibration; the peak at 338 cm-1 came from the O-Cr-O bending; and the peak at 130 cm-1 came from the ion transition in the crystal. There were six indicative peaks in the Raman spectrum of Fe2O3, which were observed at 224 cm-1, 290 cm-1, 407 cm-1, 496 cm-1, 608 cm-1, and 1310 cm-1. The intense peak at 250–260 cm-1 suggested the existence of HgS.

IR Analysis

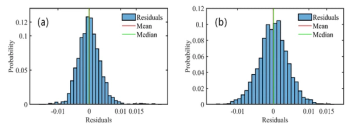

FT-IR can hardly be used to analyze the ink samples with paper substrates because of the intense absorption of cellulose in the paper, thus in the present study FT-IR was used to analyze the ink samples on slide only to verify the Raman classification results. The typical samples from each group were further analyzed with FT-IR. The results are illustrated in Figure 3 and Table III. Significant differences were observed in the IR spectra among different groups, which further supported the availability of Raman method in seal inks differentiation.

Figure 3: IR spectra of inks in different groups.

The main IR peaks of the ink sample in group 2 with bronze red C as the typical component coincided well with its Raman result and they were observed at 736 cm-1 (m), 851 cm-1 (w), 868 cm-1 (w), 1038 cm-1 (w), 1072 cm-1 (w), 1141 cm-1 (m), 1273 cm-1 (m), 1380 cm-1 (m), 1458 cm-1 (s), 1499 cm-1 (m), 1561 cm-1 (w), 1616 cm-1 (w), 1658 cm-1 (w), and 1742 cm-1 (vs). The most intense peak at 1742 cm-1 represented the stretching vibration of C=O. The intense peak at 1458 cm-1 should be assigned as the skeleton vibration of benzene ring. These two peaks and the peak at 1273 cm-1 were indicative and can be used to differentiate the group from the others.

In the spectrum of group 3 with scarlet powder as the identified component, the main IR peaks appeared at 756 cm-1 (s), 820 cm-1 (w), 878 cm-1 (w), 909 cm-1 (w), 983 cm-1 (w), 1014 cm-1 (m), 1072 cm-1 (vs), 1125 cm-1 (vs), 1188 cm-1 (vs), 1267 cm-1(m), 1333 cm-1 (w), 1361 cm-1 (w), 1381 cm-1 (m), 1446 cm-1 (vs), 1493 cm-1 (m), 1546 cm-1 (s), 1598 cm-1 (m), 1677 cm-1 (s), and 1735 cm-1 (s). The IR result was in agreement with the Raman result. The peak at 3184 cm-1 represented the absorption of OH stretching vibration; the peak at 3068 cm-1 represented the C-H in benzene ring stretching; the peak at 1677 cm-1 represented the C=O stretching; the peaks at 1594 cm-1, 1493 cm-1, and 1448 cm-1 represent the skeleton vibration of benzene ring; the peaks at 1533 cm-1 and 1332 cm-1 represent the combination of N-H bending and C-N stretching vibration; the peaks at 1014 cm-1 represent C-H in ortho-substituents of benzene in-plane bending vibration; and the peaks at 759 cm-1 and 695 cm-1 represent the out-plane bending vibration. The peaks at 1677 cm-1 and 1493 cm-1 can be easily found in the spectra of the paints containing scarlet powder with less interference in real cases.

The peak in the 850–860 cm-1 range in the FT-IR spectrum can help to identify PbCrO4; however, for Fe2O3 and HgS, IR cannot provide useful information in their identification.

Conclusions

A total of 110 seal ink samples from 37 brands collected from 10 Chinese provinces were investigated. They were successfully discriminated into 18 groups with Raman microscopy and the discrimination rate was greatly improved compared to the recent studies. No sample preparation was needed in the analysis, and high quality spectra can be obtained in only 1–2 min. Scarlet powder and bronze red C were the pigments most frequently detected in the seal inks, with detected rates of 36.4% and 31.8%, respectively; PbCrO4 (10.0%), HgS (8.2%), Fe2O3 (5.5%), rhodamine B (2.7%), and fast red (3.6%) were also detected in some samples. FT-IR on-slide analysis was used to verify the availability of the Raman method in seal inks differentiation. The indicative peak positions and intensities of all the groups in Raman and FT-IR spectra were summarized. The results showed that Raman analysis can discriminate seal inks with paper substrates as well as FT-IR on-slide analysis. The developed approach was proved to be a powerful, sensitive, and rapid method for the differentiation of ink entries of seals on documents.

References

(1) G.P. Suo, Archives, 10.3969/j.issn.1004-2733.2001.02.028 (2001) (in Chinese).

(2) X.F. Wang, J. Yu, A.L. Zhang, D.W. Zhou, and M.X. Xie, Spectrochim. Acta. A.97, 986–994 (2012.)

(3) K. Bojko, C. Roux, and B.J. Reedy, J. Forensic Sci.53, 1458–1467 (2008).

(4) Y.-T. Yao, J. Song, J. Yu, X.-F. Wang, F. Hou, A.-L. Zhang, Y. Liu, J. Han, and M.-X. Xie, J. Sep. Science, 32, 2919–2927(2009).

(5) B. Li, P. Xie, and T.C. Sun, Journal of Chinese People's Public Security University (Science and Technology). 10.3969/j.issn.1007-1784.2008.02.010 (in Chinese).

(6) M. Li, B. Jia, L. Ding, F. Hong, Y. Ouyang, R. Chen, S. Zhou, H. Chen, X. Fang, J. Mass. Spectrom. 48, 1042–1049 (2013).

(7) P. Xie, C. Feng, B. Li, and R. Bao, Journal of Chinese People's Public Security University (Science and Technology) 2,19–23 (2013).

(8) J.X. Zou, L.X. Lin, Y. Chen, G.J. Shi, and A.D. Yang, Forensic Science and Technology 1, 6–9 (2013).

(9) J. Song, Y.L. Li, L. Li, and M.X. Xie, China Modern Education Equipment10, 32–34 (2007).

(10) Q. Zhang, J.X. Zou, G.J. Shi, and L.J. Zhang, Chin. J. Chromatogr.28, 1132–1136 (2007).

(11) X.F. Wang, Y. Zhang, Y. Wu, J. Yu, and M.X. Xie, Forensic Sci Int.236, 99–108 (2014).

(12) Q. Zhang, "Water-Based Ink Blots and Stability of Principal Component Analysis," thesis of masters degree, Beijing University of Chemical Technology (2011).

(13) X.Y. Luo, F. Ye, L.M. Wu, S.W. Yuan, W.B. Zhang, and Y.P. Du, Spectrosc. Spect. Anal. 30, 2405–2408 (2010).

(14) A. Raza and B. Saha, Sci. Justice. 53, 332–338 (2013).

(15) Y.F. Wang and B. Li, Sci. Justice. 52, 112–118 (2012).

(16) W. Dirwono, J.S. Park, A. Camacho, J. Kim, H.M. Park, Y.H. Lee, and K.B. Lee, Forensic Sci. Int. 199, 6–8 (2010).

(17) L. Burgio and R. Clark, Spectrochim. Acta A.57, 1491–1521 (2001).

(18) M.R. Marcelino and V.S.F. Muralha, J. Raman Spectrosc. 43, 1281–1292 (2012).

(19) X.F. Wang, J. Yu, A.L. Zhang, Z. Zhang, and M.X. Xie, Spectrosc. Spect. Anal.28, 255–256 (2008).

(20) S. Liu, J.M. Feng, W. Zhang, and J.G. Lv, Pigm. Resin. Technol. 43, 45–51 (2014).

Jungang Lv, Shuo Liu, Yuanyuan Li Jimin Feng, Yong Liu, and Songdong Zhou are with the Procuratoral Technology and Information Research Center at the Supreme People's Procuratorate in Beijing, China. Direct correspondence to:

Articles in this issue

almost 11 years ago

How Do You Prepare Reference Standards and Solutions?almost 11 years ago

Electromagnetic Radiation, Spectral Units, and Alkanesalmost 11 years ago

LIBS Detection of Nanomaterials for Process Control and in the Workplacealmost 11 years ago

What ICP Spatial Heterogeneity Reveals About Interference in ICP-AESalmost 11 years ago

App of the Month: Shimadzu IRalmost 11 years ago

Vol 30 No 4 Spectroscopy April 2015 Regular Issue PDFNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.

![Figure 3: Plots of lg[(F0-F)/F] vs. lg[Q] of ZNF191(243-368) by DNA.](https://cdn.sanity.io/images/0vv8moc6/spectroscopy/a1aa032a5c8b165ac1a84e997ece7c4311d5322d-620x432.png?w=350&fit=crop&auto=format)