- Special Issues-10-01-2006

- Volume 0

- Issue 0

Elemental Analysis of Edible Oils and Fats by ICP-OES

The analysis of edible oils and fats by inductively coupled plasma–optical emission spectroscopy (ICP-OES) utilizing direct injection after dilution with kerosene is described. Sample preparation was performed according to EN ISO 661 (1) and ISO 10540-3 (2). The accuracy was investigated using the AOCS reference sample, "Trace Metals in Soybean Oil" (3) and by spike recovery measurements using commercial sunflower oil. The analysis requirements for sensitivity, precision, and accuracy were met. This article includes line selection, detection limits, and accuracy studies.

Oils and fats, particularly vegetable oils, are essential for a healthy diet because they provide the body with nutrients and are low in cholesterol, rich in unsaturated fatty acids, aid in the absorption of vitamins, and act as a carrier of flavors. Oils and fats are produced from oilseeds as well as from animal sources. In 3500 B.C., the fruit of the olive tree was used to produce oil in Crete. Today, over 100 million tons of oils and fats are produced each year. While the great majority is for human consumption, there is a growing percentage produced for industrial applications like the production of detergents, cosmetics, and coatings. The use of oils as biofuels is also a growing sector.

There are a variety of techniques for extracting the oil from the raw material, including distillation, expression, and solvent extraction. To remove undesirable substances from the crude fats and oils that influence flavor, color, and quality, several purification stages might be required. These include degumming, refining, bleaching, deodorization, fractionation, hydrogenation, and interesterification.

Vegetable oils naturally contain high amounts of P (phospholipids), Ca, and Mg as well as trace levels of Fe and Cu. Higher concentrations of these elements affect the quality of the product because they influence flavor, color, and the shelf life of the oil. The same applies to Ni, which is used as a catalyst during the production process and needs to be removed in order to avoid oxidation of the product. Contamination levels of Pb and As need to be controlled in the final product.

Table I: Codex Standards for several types of oils and fats

The Codex Alimentarius Commission was created in 1963 by the FAO and WHO to protect the health of consumers and the quality of the product and to enable fair trade practices in the food trade. It has developed several codex standards for oils and fats (see Table I). The following apply:

- Edible fats and oils — CODEX STAN 19-1981 (4)

- Named vegetable oils — CODEX STAN 210 (5)

- Named animal fats — CODEX STAN 211-199 (6)

- Olive oils and olive pomace oils — CODEX STAN 33-198 (7).

Due to its multi-element determination capability, high dynamic linear range, and sensitivity, inductively coupled plasma–optical emission spectroscopy (ICP-OES) is used widely for the analysis of oil and fats. The application is described in standard procedures such as ISO 10540-3 (2) and AOCS Ca 17-01 (8).

Experimental

Instrumentation

All measurements were performed with the SPECTRO GENESIS ICP optical emission spectrometer (SPECTRO Analytical Instruments, Kleve, Germany) with radial plasma observation. The instrument includes a Paschen–Runge mount spectrometer that consists of two hollow section cast shells, designed for direct thermal stabilization and small volume. A fast, simultaneous spectrum capture of the 175–777 nm wavelength range is performed by 15 prealigned linear CCD detectors, installed externally from the optics body.

For UV access (<200 nm), the optical system can be purged with argon (optionally, nitrogen can be used). The purge rate during normal operation is 0.5 L/min.

To enable method transfer between individual instruments, ICAL (intelligent calibration logic) was used to normalize the wavelength and the intensity scale of the optical system to a reference optic ("optic master").

Exceptional stability of the forward power in the case of rapidly changing sample loads is achieved by using an air-cooled ICP generator, based upon a free-running 27.12-MHz system. All ICP operating parameters were software controlled.

A Burgener T2002 nebulizer (Burgener Research Inc., Mississauga, Ontario, Canada) and a Tracey cyclonic spray chamber (Glass Expansion, Melbourne, Australia) were used for sample introduction. The operating conditions are given in Table II.

Table II: Operating conditions - direct aspiration after dilution, radial plasma observation

Sample Preparation

Sample preparation was performed according to EN ISO 661 (1) and ISO 10540-3 (2). The norms include the following procedure:

Liquid Samples

Clear samples without sediment: To guarantee sample homogeneity, the samples must be well mixed before dilution.

Turbid samples, or samples with sediment: Turbid samples or samples with sediment are placed in a drying oven, which is controlled at 50 °C. The samples are left in the oven until they have reached the set temperature, are well mixed to ensure homogeneity, and are diluted as described in the following sections. If, after heating and mixing, the samples are not completely clear, the described method cannot be applied. In such a case, good recoveries can be achieved only if the samples are digested before the analyses when using ICP-OES as the analytical technique.

Solid Samples

The samples are melted in a drying oven, which is controlled at a temperature of at least 10 °C above the melting temperature of the particular fat or oil. If, after heating, the sample is perfectly clear, the samples are well mixed to ensure homogeneity and are diluted as described as follows.

In the case of turbidity or if the samples contain sediment, the described method cannot be applied.

Again, good recoveries can be achieved only if the samples are digested before the analyses when using ICP-OES.

Sample Preparation

A 2.5-g (±0.02 g) amount of sample was weighed into an autosampler tube and diluted with 2.5 g kerosene. (Note: 1-Butanol or xylene also can be used as the dilution solvent. 1-Butanol is more suitable as a solvent if the samples contain higher levels of moisture.) A 1-mg/kg concentration of Sc was added as an internal standard to all solutions. The sample tubes were closed and mixed 40–50 times.

Calibration Standards

Refined, bleached soybean oil was used as a blank. The oil was diluted 1:1 using kerosene. As a reference base, oil 20 (Conostan, Conoco Phillips Company, Ponca City, Oklahoma) was used to determine that the blank oil was free from trace element contamination.

Table III: Calibration standards

The standards were prepared using commercially available Conostan (S21-100) standard solution and Conostan single-element standard solutions for As. To adjust the required concentrations given in Table III, the standards were first diluted with base oil 20 and then further diluted 1:1 using kerosene as a solvent. A 1-mg/kg concentration of Sc was added as an internal standard to all solutions.

The QC of the method was performed using the AOCS reference material "Trace Metals in Soybean Oil" (3) and by spike recovery measurements using commercial sunflower oil.

Table IV: Limits of detection (LOD) for the selected elements and lines

Results and Discussion

Table IV shows the selected wavelengths and the limits of detection (LOD). The LODs were calculated according to the following equation (9):

LOD = 3 RSDbc/SBR

where RSDb is the relative standard deviation of 10 replicate measurements of the blank sample, c is the concentration of the standard, and SBR is the signal-to-background ratio.

The LODs were calculated referring to the original sample (2.5 g sample diluted with 2.5 g kerosene).

Table V: Spike recovery analysis using commercial sunflower oil. Comparison of the given with the measured concentrations.

Accuracy

The accuracy of the calibration curve was confirmed using commercial sunflower oil, spiked with 1 mg/kg of the relevant elements using Conostan (S21-100) and Conostan single-element solutions and the AOCS reference material "Trace Metals in Soybean Oil." Comparison of the results with the reference values (Tables V and VI) shows good agreement. A precision between 0.2% and 1.1% RSD was found for 10 replicate measurements.

Conclusion

ICP-OES offers a simple, fast, accurate, and precise method for the simultaneous determination of trace elements in edible oils and fats.

For clear oil samples, the direct aspiration technique after dilution with kerosene gives good sensitivities, is easy to apply, is fast, and thus offers higher sample throughput. Difficulties arise when the samples contain higher levels of sediments.

Table VI: Comparison of the reference values with the measured concentrations for the AOCS reference material "Trace Metals in Soybean Oil"

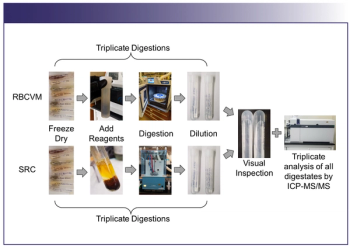

In these cases, continuous agitation of the sample is needed to determine the total amount of impurities. Still, because particle transport, vaporization, and excitation are limited to a size of less than 10 µm, larger particles are not considered for the analysis. Complete mineralization of the sample is the preferred preparation technique to enable accurate analyses in such cases. Also, for fat samples with low solvent solubility, automated high-pressure, closed-vessel microwave digestion is an efficient sample preparation technique. Disadvantages as a result of the higher dilution can be moderated by the use of additional sample introduction techniques, such as pneumatic nebulization with solvent removal (10).

D. Ardelt, P. Ivanov, and O. Schulz are with SPECTRO Analytical Instruments, Kleve, Germany

References

(1) ISO 661, Third Edition 2003/15/05, Animal and vegetable fats and oils — preparation of test sample.

(2) ISO 10540-3, First Edition 2002/12/1, Animal and vegetable fats and oils — determination of phosphorus content; Part 3: Method using ICP-OES.

(3) American Oil Chemist Society, Reference sample: "Trace Metals in Soybean Oil."

(4) FAO/WHO Codex Alimentarius Commission, CODEX STANDARD FOR EDIBLE FATS AND OILS NOT COVERED BY INDIVIDUAL STANDARDS, CODEX STAN 19-1981 (Rev. 2-1999).

(5) FAO/WHO Codex Alimentarius Commission, CODEX STANDARD FOR NAMED VEGETABLE OILS, CODEX-STAN 210 (Amended 2003, 2005).

(6) FAO/WHO Codex Alimentarius Commission, CODEX STANDARD FOR NAMED ANIMAL FATS, CODEX-STAN 211-1999.

(7) FAO/WHO Codex Alimentarius Commission, CODEX STANDARD FOR OLIVE OILS AND OLIVE POMACE OILS, CODEX STAN 33-1981 (Rev. 2-2003).

(8) American Oil Chemist Society, AOCS Recommended Practice Ca 17-01, approved 2001.

(9) P.W.J.M. Boumans, Spectrochim. Acta 46B, 431 (1991).

(10) Elemental Scientific, Inc., Omaha, Nebraska.

Articles in this issue

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.