Improving Drug Formulation Studies by Lowering the Detection Limits of Powder XRD

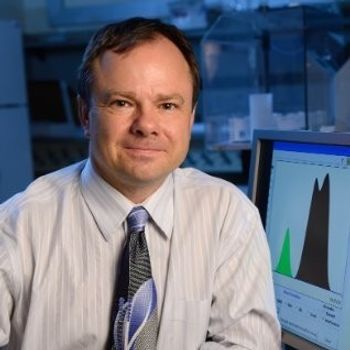

Roughly half of all promising new drug candidates are abandoned because of poor aqueous solubility. As a result, many pharmaceutical researchers are pursuing amorphous formulations, which can show improved solubility. Those researchers need powerful analytical tools to study the trace crystalline structures in those drugs, however. To address this problem, Garth Simpson of Purdue University has developed a powder X-ray diffraction (XRD) method with 100 ppm detection limits. He recently spoke to us about this work, for which he won the 2014 FACSS Innovation Award.

Roughly half of all promising new drug candidates are abandoned because of poor aqueous solubility. As a result, many pharmaceutical researchers are pursuing amorphous formulations, which can show improved solubility. Those researchers need powerful analytical tools to study the trace crystalline structures in those drugs, however. To address this problem, Garth Simpson of Purdue University has developed a powder X-ray diffraction (XRD) method with 100 ppm detection limits. He recently spoke to us about this work, for which he won the 2014 FACSS Innovation Award.

Your winning FACSS presentation was on reducing the detection limits of powder XRD of amorphous pharmaceutical formations. First, why was this an important goal?

Among the numerous requirements for formulating safe and effective pharmaceuticals, the aqueous solubility of the active pharmaceutical ingredient (API) is among the most important. Unfortunately, many promising new potential drug candidates are abandoned as therapeutics due to insufficient aqueous solubility. Amorphous formulations have emerged as a potential solution to this problem: For many APIs exhibiting poor aqueous solubility in the crystalline phase, the amorphous phase may provide a large enough increase in the aqueous solubility such that a bioavailable formulation could be produced. Underpinning such formulation efforts is the need for the detection, quantification, and characterization of trace crystallinity within the solid state. Current powder XRD instrumentation suffers from relatively high limits of detection. This is problematic, as fully crystalline and fully amorphous states of a low-dose formulation could be nearly indistinguishable by conventional powder XRD. Lowering the limits of detection of powder XRD could alleviate this problem.

You mentioned that second-harmonic generation (SHG) microscopy provides excellent detection limits for this purpose. So why don’t we just use that technique?

Both quantitative and qualitative analyses provide a more complete description. Although SHG microscopy is excellent at quantitation, the SHG intensity alone provides little meaningful information for characterizing unknown samples. In contrast, XRD provides rich structural information related both to composition and crystal form. Pairing the two, we gain the advantages of both trace analysis and structural identification.

What were the challenges involved in implementing SHG-guided powder XRD, and how did you overcome those challenges?

The largest hurdle was designing an instrument that could quickly and easily identify a region of interest by SHG, then perform the targeted diffraction in precisely that location with ~1 mm absolute accuracy. It ultimately required integrating an SHG microscope into the existing X-ray instrumentation at the synchrotron facility at Argonne National Laboratory. Because of the space constraints of the existing instrumentation, we were allotted a 1 ft x 1 ft platform to house all of the optics required for the microscope. To give you a sense for the magnitude of this endeavor, the instruments in our lab typically occupy the entirety of a 4 ft x 8 ft laser table. A lot of work went into condensing the number of optics and the spacing between optics to meet the space constraints, integrating our software into the control software for the beamline, and the numerous safety requirements for locating a class IV laser in the experimental hutch. We were truly fortunate to work with some outstanding scientists at the beamline willing to collaborate with us to make this happen.

What results have you been able to achieve with your approach?

By the very nature of the recognition of this work through the Innovation Award, we are still necessarily at an early stage and just scratching the surface. Perhaps the most exciting of our results to date is the collection and successful indexing of diffraction data at a 100 ppm crystal loading, which represents about a 10,000-fold improvement over that of a conventional benchtop instrument.

One of the exciting things about new measurement capabilities is that it can be hard to predict the interesting nuggets you may stumble across. In fundamental studies of cryogenically cooled glasses, we found that SHG can directly image the electric fields generated upon localized X-ray exposure (1). Furthermore, these fields turn out to be quite large, and may even play a significant role in the loss in resolution observed during macromolecular crystallography data collection. This result would not have been obvious to us without the ability to integrate the SHG microscopy directly with synchrotron XRD.

What are your next steps in this work?

Raise the main, and point the bow toward uncharted waters. Goals currently on our immediate horizon include pushing the detection limits further down into the low parts-per-million regime, mapping the spatial distributions of crystal forms within complex, multi-component powders, structural analysis of trace contaminants and rare species, and fundamental studies relating the polarization-dependence of SHG to crystal orientation. We’ll also be focusing on ways to integrate microfocus X-ray sources for similar analyses using benchtop instrumentation. Beyond that, it is dangerous to speculate on the adventures and challenges awaiting us.

References

(1) C.M. Dettmar, J.A. Newman, S.J. Toth, M. Becker, R.F. Fischetti, and G.J. Simpson, PNAS 112(3), 696–701 (2015).

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.