- Spectroscopy-03-01-2019

- Volume 34

- Issue 3

The LIBS Advantage in Mining and Energy Applications

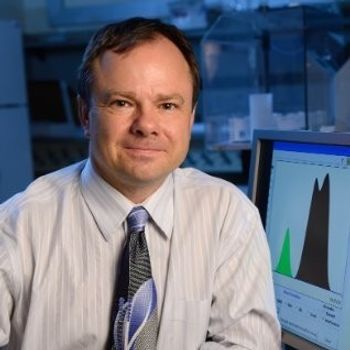

Laser-induced breakdown spectroscopy (LIBS) has seen significant expanded adoption in recent years, particularly in industrial applications where it can provide important advantages over other techniques. Mohamad Sabsabi, of the National Research Council of Canada, has been leading programs to research and implement the use of LIBS in mining and energy applications.

Laser-induced breakdown spectroscopy (LIBS) has seen significant advances and expanded adoption in recent years. In particular, LIBS is being implemented in industrial applications, where it can provide important advantages over other techniques. Mohamad Sabsabi, of the National Research Council (NRC) of Canada, has been leading programs to research and implement the use of LIBS in mining and energy applications. He recently spoke to us about this work.

You recently used LIBS to analyze gold in rock samples (1). How did this project come about?

Exploration of precious metals is very challenging, because the cutoff grade continues to decrease as the value of metals increases. The gold mining industry is looking for technologies that allow fast, in situ analysis to allow them to make decisions in the field, such as adjusting sampling plans, testing hypotheses based on ongoing results, and making fast decisions on exploration work, especially drilling and sampling. This is particularly important for remote locations, where the logistics of getting samples to a laboratory may be slow and demanding.

(Tom Fullum/Getty Images)

So, the mining industry is on the lookout for new technologies that meet their cost reduction needs. One of these innovative technologies, the development of which would be a major breakthrough, is the measurement of precious metal concentrations in ore, in real time and on site, during various stages of exploration and mining. In the case of gold, this technology needs to be able to measure an average concentration down to ~1 ppm, because gold is still worth extracting at such a low concentration. Existing technology for the direct analysis of gold in solid samples, such as infrared (IR) spectroscopy, allows determination of the mineralogy of the rock samples (which often include quartz, pyrite, chalcopyrite, sphalerite, and arsenopyrite), but the elemental composition is out of reach of this technique. XRF has been used successfully for determining the concentration of some basic metals, such as copper, zinc, and nickel, but it is inadequate for quantifying gold concentration, because of its low sensitivity and poor limit of detection (LOD). In addition, portable X-ray fluorescence (XRF) systems are not sensitive enough for gold detection in the ppm range required by the industry, and XRF suffers from interference with zinc and iron, which give false values for gold and compromises its determination.

LIBS appears to be a good candidate for gold detection. The idea of using LIBS for gold is not new. In our laboratory, we pioneered the work 24 years ago, in collaboration with the Centre de Recherches Minerales (CRM), now called COREM, in Quebec. We showed the proof of concept of feasibility in the laboratory in terms of sensitivity and quantification on synthetic samples. However, the LIBS components at that time were not adequate for on site applications in terms of robustness, portability, and performance. At the time, for the detection system we were using an intensified photodiode array (IPDA)-which is now outdated and has been replaced by an intensified charge coupled device (ICCD)-that was bulky and needed a chiller for cooling the photodiode array, a delay generator, and a high voltage source for the intensifier. In the last six years, the advent of new enabling components has encouraged the NRC LIBS team to renew its interest and reconsider the project within the newly initiated NRC High Efficiency Mining program and in collaboration with major Canadian gold mining companies, the Université Laval, in Quebec City, and the Institut National de Recherche Scientifique (INRS).

What were the main obstacles you had to overcome?

Analyzing a mineral ore sample is not an easy task for the analytical chemist. There are very few works in the literature devoted to LIBS analysis of gold in ore samples. There are many challenges related to such an investigation, including 1) the heterogeneity of the gold distribution and the lack of natural gold ore reference samples, 2) variation in the mineralogical matrix in ore samples, 3) the fact that gold is embedded in several matrices-silica, quartz-chlorite, and pyrite, with the particle size varying from sub µm up to few tens of µm, 4) the complexity of their natural mixing matrices for analytical purposes, 5) the complexity of characterization of the laser induced plasmas, and 6) sensitivity to the sub-ppm level of gold concentration, which requires optimized components and conditions for gold detection.

In terms of a functional LIBS-based device, these challenges translate into: 1) adequately sampling the surface of the mineral to accurately evaluate the gold concentration, 2) resolving the matrix effects that result in variations of the spectroscopic signal of gold with the compositions of the ore, 3) finding ways to prepare synthetic samples to match natural rock samples for quantitative analysis, 4) reconciling bulk analysis by conventional techniques based on wet chemistry with the surface analysis given by LIBS, 5) developing strategic sampling plans to ensure representative sampling to build confidence in the analysis, 6) having appropriate depth of field to avoid problems with surface roughness, and 7) resolving the water effect.

What were your main findings?

We have used LIBS for evaluating the concentration of gold in mineral samples of practical interest, namely fine and granular powders, and drill cores. The calibration curve was established using 44 synthetic samples made of compressed powders of different compositions containing a quasi-uniform distribution of gold. The samples represent the types of ore we find in the Canadian Shield. We found that the calibration curve for the Au I 267.59 nm line splits into two branches: one for Si-rich samples (5% iron), and one for Fe-rich samples (15% iron), with limits of detection of 0.8 ppm and 1.5 ppm, respectively, thus nearly meeting the needs of the mining industry in term of the detection limit for the determination of gold concentration (~1 ppm). We showed that normalizing the gold line intensity with respect to the integrated spectrum intensity or with respect to the spectral background (plasma continuum emission) close to the gold line improves the regression fit of the calibration curves, as compared to not normalizing. The use of one branch or the other of the calibration curve can be determined from the continuum generated by iron in the samples. In practical cases, because the gold is particulate in the ore, the LOD for gold in rock samples can be even lower in inhomogenous samples. When LIBS is compared to fire assaying or atomic absorption (AA) for the analysis of homogenous samples, there is a good agreement between the results obtained by the two techniques for the same sample. However, on core samples or bulky rocks, the discrepancies are more related to the inhomogeneity of the samples, rather than disagreement between the two techniques. This has been verified by conventional techniques on the two halves of the same core being analyzed by the same technique. Our work constitutes a first step toward determining gold concentration in practical mineral samples using LIBS. It shows that LIBS can detect gold in the ppm range and provides a proof of concept for quantitative analysis of gold ore samples in reference materials, whether synthetic or powdered samples.

What are the next steps in this work?

As pointed out above, several questions remain to be addressed. Some of the main questions are the following: 1) Can the calibration curve established from compressed powders be used for solid samples such as granular powder or rocks? 2) Does the cutting process of drill cores or rocks affect the gold concentration at the surface of the sample? 3) How can we automatically identify the gold concentration independently of the matrix? 4) How can we scan the rock samples in an optimal way, so as to minimize the effects of heterogeneity of the gold concentration with a minimal number of laser shots? 5) How does the water content or dust on the surface affect the analysis? 6) How does the water content affect the analysis for the chips sample? 7) What is the best sampling pattern to minimize the number of shots without compromising the reproducibility of the measurement and still ensure representative sampling? 8) Is there a way to address the issue of standards for calibration in particular for higher concentrations (100 ppm and above)? All these questions are currently under investigation.

You have also used LIBS for the rapid determination of bitumen content in Athabasca oil sands (2). Can you tell us about that work?

The Athabasca oil sands in Canada are considered to be the largest oil sand reserves in the world. Oil sands are heterogeneous mixtures composed of about 4-18% of bitumen, about 65-80% of mineral solids, and about 2-15% of water. Oil produced from oil sands by open pit mining methods involves the basic steps of mining the oil sands, bitumen recovery by flotation, upgrading for synthetic oil, and finally refining. Prior to the recovery of bitumen by flotation, it is important to characterize the oil sands feedstock ore content to optimize the process, and make a decision from the perspectives of the environment and economic value.

These measurements can be done in the laboratory, or on a conveyor to monitor the feedstock. However, current methods for assessing oil sands content are time consuming and labor intensive, as well as difficult to control, because of the complexity and heterogeneity of the samples that contain different particle sizes and several minerals. The industry standard for determining bitumen, water, and solids contents of oil sands ore samples is the Dean-Stark extraction method. Extraction of bitumen from the solids takes several hours to complete. Once the three components have been separated, the clean and dry minerals can be identified and quantified by a variety of techniques, including elemental analysis by inductively coupled plasma optical emission spectrometry (ICP-OES), and mineralogy by X-ray diffraction (XRD). Given the difficulties mentioned above, the oil sand industry needs a breakthrough technology able to determine the bitumen content quickly and without sample preparation, either in the laboratory or online. LIBS appears to be a potential candidate technique to meet that need. We investigated the potential of LIBS for this application.

What were your main findings?

We investigated the application of LIBS to Athabasca oil sands samples to find a correlation between LIBS spectra and bitumen content. In particular, we focused on evaluating the potential of LIBS to meet the requirements of the oil sands industry in terms of analytical performance for the determination of the bitumen content without sample preparation. The analysis of bitumen ore samples is very challenging because of the heterogeneous nature of the mixture of bitumen, water, and mineral content. A qualitative study was done first, and then a multivariate quantitative method was performed to assess the feasibility of determining bitumen by LIBS. The results show a good correlation between LIBS spectra and bitumen content, and a prediction averaged absolute error <1%. Our results showed that the combination of LIBS and chemometrics proved to be a novel rapid quantitative method for assessing bitumen in oil sands without sample preparation and with only a few calibration samples. The method represents a real alternative to methods traditionally used in the oil sands industry. Moreover, given that the LIBS fingerprint is information-rich, this method could also provide additional information about elemental solid composition, and, therefore, some key elements related to either clays or quartz signature evaluation. So several potential applications can be targeted for rapidly assessing oil sands on a conveyor to evaluate the feedstock grade, or ore grades, either in the laboratory, at-line, or online.

Do you plan to develop this work further?

Future work includes XRF and XRD analyses to validate the feasibility of the LIBS technique for minerals and clays estimation. More samples with wide mineralogical types and bitumen composition will be studied to investigate various sampling strategies, and to improve the precision and the accuracy of bitumen prediction.

Are you planning to develop LIBS for any other areas of research?

In our laboratory, we will continue working on improving the analytical performance of LIBS to be implemented as a technology for problems in society, with a focus on natural resources. We will keep taking into account the discovery of new enabling tools and components and the increase in hyphenated systems that will enable more sophisticated analysis and thereby, boost market growth.

References

(1) K. Rifai, M. Laflamme, M. Constantin, F. Vidal, M. Sabsabi, A. Blouin, P. Bouchard, K. Fytas, M. Castello, and B.N. Kamwa, Spectrochim. Acta, Part B 134, 33–41 (2017).

(2) A. Harhira, J. El Haddad, A. Blouin, and M. Sabsabi, Energy Fuels32, 3189-3193 (2018).

Mohamad Sabsabi is a principal research officer in the Energy, Mining, and Environmental Research Center at the National Research Council (NRC) of Canada. He received his Ph.D. in physics from the Université de Paris (France) in 1988. After conducting postdoctoral research on thermal plasmas at the Université de Sherbrooke, in Quebec, Canada, he joined the NRC in 1992 where he initiated activities in laser plasma spectroscopy and built a team among the most active in this field. Sabsabi and his team have succeeded in pioneering and implementing laser-induced breakdown spectroscopy (LIBS) technology for many applications. In particular, the LIBS method developed by the NRC LIBS team has been implemented in the five continents for the analysis of molten materials because there is no alternative conventional method. He initiated and led, for four years, the NRC High Efficiency Mining (HEM) program that aims to bring improvements throughout the mining value chain by developing advanced sensors, process technologies, and advanced materials. From Sabsabi's inventions, there have been two spin-off companies and six technology transfers in applications of LIBS in the mining, agricultural, metallurgical, pharmaceutical, and manufacturing industries. He holds 18 patents and has more than 500 publications (papers and conference presentations) covering fundamental aspects and industrial applications of laser-induced plasmas.

Mohamad Sabsabi

Articles in this issue

almost 7 years ago

Vol 34 No 3 Spectroscopy March 2019 Regular Issue PDFalmost 7 years ago

Raman Spectroscopy and Polymorphismalmost 7 years ago

Organic Nitrogen Compounds II: Primary Aminesalmost 7 years ago

2019 Salary Survey: Some Unusual Trendsalmost 7 years ago

Trends in Spectroscopy: A Snapshot of Notable Advances and ApplicationsNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.