- January 2022

- Volume 37

- Issue 1

Key Steps to Create a Sample Preparation Strategy for Inductively Coupled Plasma (ICP) or ICP–Mass Spectrometry (ICP-MS) Analysis

How to create trouble-free sample preparation workflow for elemental analysis.

Inductively coupled plasma (ICP) is a well-known source for atomic spectroscopy, either using optical emission spectroscopy (OES) or mass spectrometry (MS) as a detection technique. The high energy and temperatures in an ICP (typically between 6,000 to 8,000 °C) lead to an efficient and complete decomposition of the sample as well as the vaporization, excitation, and possibly ionization of atoms in their gas phase. The high temperature of the plasma makes this source inherently robust and tolerant to a wide variety of sample types (such as solutions containing an elevated percentage of dissolved solids, different acids, and organic solvents). However, inadequate sample preparation, or inappropriate configuration of the sample introduction system, can have negative consequences such as drift of the analytical signal, increased backgrounds, inadequate detection limits, or unexpected interferences. This tutorial highlights the most important steps necessary for creating a trouble-free sample preparation workflow for elemental analysis.

Inductively coupled plasma–optical emission spectroscopy (ICP-OES) and ICP-mass spectrometry (MS) are designed primarily to analyze samples in liquid form. In most cases, a sample must be dissolved (if possible) in a suitable diluent. Whereas aqueous diluents, like ultrapure water or dilute acids, are generally easier to handle, organic solvents are commonly applied, for example, to determine elemental impurities in certain active pharmaceutical ingredients. In the event a sample is not immediately soluble, a digestion method using a hot block, fusions (for example, lithium metaborate), or a microwave-assisted digestion are often the only routes to analysis. However, all the aforementioned approaches have common drawbacks, such as the time required for the digestion, the cost of reagents, and the requirement to invest in digestion hardware. In addition, contamination could become a problem from the reagents used for digestion, or the insufficient cleaning of crucibles or digestion vessels between samples.

Irrespective of the digestion method used, a clear and particle-free solution is the ideal outcome of the digestion process. However, before introducing this solution to the analytical instrument of choice, it is important to consider a few parameters. The amount of total dissolved solids (TDS) is calculated by dividing the amount of sample used for digestion by the final volume of the solution after digestion. The maximum working range for TDS is different between ICP-OES and ICP-MS and is highlighted later in this tutorial. The remaining acid concentration and the acid mixture can have an influence on not only the performance of the instrument, but also the configuration of the sample introduction system. If hydrofluoric acid (HF) is used, it is important to exchange all components made from quartz for their inert replacements. Ideally, the remaining acid concentration in a digested sample should be below 5% (v/v).

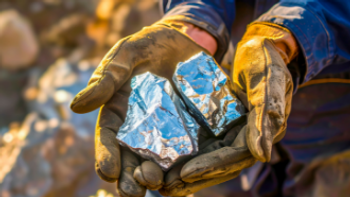

The direct analysis of solid samples can be an alternative in some cases, such as conducting samples (metals and semiconductors), nonconducting samples (mineral grains, paper, and plastics), and biological materials (tissue sections). Using a laser system focused directly on the surface of the sample, short pulses of high-intensity light can convert a solid sample directly into an aerosol, which is transported to the ICP ion source for analysis. Laser ablation (LA) enables direct sampling of a range of solid materials without the need for hazardous chemicals and minimizes the potential for contamination by sample handling. Because of the typical small spot size of approximately 200 μm, laser ablation is considered quasi nondestructive and can therefore be an alternative approach for analyzing valuable samples.

However, sample homogeneity can be an issue when LA-ICP-MS is employed for concentration determinations in a bulk material, so careful selection of the sampled area is required. On the other hand, LA-ICP-MS also allows information to be obtained on the lateral distribution of an analyte across a sample, which is beneficial for characterizing geological or biological samples.

Consider Acid and Vial Purity!

ICP-OES and ICP-MS are technologies for analyzing elemental impurities at trace and even ultratrace levels. As a result, backgrounds for the analytes of interest must be as low as possible. Otherwise, false positive results and poor detection limits may cause significant follow-on work in a routine operating laboratory. For many elements, such as the rare earth elements, natural abundance in the environment is low and so there is likely no background contamination found in the water and acids or the vials used during sample preparation. For other elements, especially alkali, alkaline earth, and transition metals, such as sodium, potassium, iron, copper, or zinc, there may be significant amounts leaching out from plasticware such as vials and vial caps. When changing from batch to batch or between different brands, a preliminary leach test for purity of vials is highly recommended.

Lower purity acids may also add to the backgrounds observed in an analysis. Acids and other reagents typically used in elemental analysis, such as nitric and hydrochloric acid or hydrogen peroxide, are available in different purities, but especially for ultratrace analysis using ICP-MS, only the highest purity should be used.

As an alternative, lower-purity acids can be purified using sub-boiling distillation, which is a cost-effective way to increase the purity of a less expensive acid. Another potential contribution to contamination can be the water used for the preparation of diluent solutions. A regular check for trace elements is highly recommended, as well as regular maintenance of the water purification system (as per the manufacturer recommendations). For trace element analysis, it is recommended to use water with a resistivity of 18.2 MΩ cm wherever possible.

Choose Your Acids Wisely!

Many sample types only dissolve well using microwave-assisted digestion, which aids the decomposition of difficult matrix materials by enabling digestions to be run at higher temperatures and pressures. However, despite the conditions, the selection of the right acid is still crucial, and in many cases, an effective digestion will often require a combination of different acids or oxidationents. The use of an acid mixture also allows for immediate stabilization of some elements in solution. Whereas nitric acid (HNO3) is often used as a diluent for elemental analysis, it is mostly ineffective for sample digestion alone. In combination with hydrogen peroxide (H2O2), effective decomposition of mostly organic matrices (such as food and feed), can be achieved. As an alternative, perchloric acid can be used to increase the oxidation potential of the mixture, but extreme care is recommended as perchloric acid can react strongly and rapidly with organic matrices. The addition of a suitable amount of hydrochloric acid (HCl) is beneficial to unlock and stabilize certain inorganic materials. In many cases, aqua regia (a combination of hydrochloric acid with nitric acid in a 3:1 mixture) is effective for dissolving metallic materials. Hydrochloric acid can also help stabilize critical contaminants, such as mercury and platinum group metals, in the digested sample. For this purpose, it is important to ensure the concentration of HCl is high enough (2% or even higher), so that initially formed precipitations (HgCl or HgCl2) are converted into soluble chloro complexes ([(HgCl4)]2-). All acids typically added in digestion methods are summarized in Figure 1. Sulfuric acid can be beneficial for digesting some sample types on a hotplate and in some types of high pressure digestion systems, but this acid should never be used with Teflon vessels in a microwave because Teflon melts at a temperature lower than the boiling point of sulfuric acid at atmospheric pressure. In addition, sulfuric acid generates several additional sulfur-based interferences in ICP-MS, so it should only be used when there is no alternative.

For any of the above, it is of utmost importance that appropriate personal protective equipment is always worn when handling acids and other hazardous chemicals. Detailed guidance on the right acid or acid mixture, sample and acid amount as well as temperature program can be obtained from the manufacturer of the microwave digestion system available in the laboratory.

Dilute Your Sample Smartly!

Samples with an elevated content of dissolved solids can cause signal suppression and drift with ICP-MS. The typical upper limit for the TDS content in ICP-MS is between 0.2 and 0.5% (m/v). This means that many samples, which can be run without any prior dilution on an ICP-OES, need to be diluted first for ICP-MS analysis. Special sampling accessories on the front end of the ICP-MS, such as dilution with argon gas, can enable the direct aspiration of solutions containing TDS well beyond 3 to 4%, but dilution is also taking place here, ultimately reducing the detection sensitivity of the system. The biggest advantage of such accessories is that a manual dilution step in the sample preparation can be omitted, which liberates operator time, reduces cost and waste created by diluent solutions, prevents contamination, and avoids human error. However, as the dilution gas affects the plasma conditions, the resulting dilution factor needs to be fixed across all standards and samples in a batch. Because of the changing plasma conditions during the measurement, long stabilization times are required after a change in the plasma conditions to avoid instrumental drift. For analyses containing different sample types, this limited flexibility becomes a drawback because with the dilution factor set to enable the measurement of higher matrix samples, lower matrix samples will be diluted more than is necessary, leading to poorer method detection limits (MDLs) and degraded accuracy for those samples.

Flexible dilution for every sample in a batch is possible using automated and intelligent liquid dilution. Automated liquid dilution is possible in conjunction with valve systems, which are available as an extension to the standard configuration of the autosampler. Using integrated control in the ICP-MS software, either a fixed liquid dilution factor for all samples or different factors (up to several hundred) for each sample can be predefined before starting the analysis. In addition, the system can also be set up to intelligently dilute further and automatically re-analyze samples that exhibit internal standard suppression higher than the acceptable limits or have concentrations outside of the calibrated range on their initial measurement. The repeat analysis data are accurately documented in the software together with the new dilution factor, so that no issues with regulatory compliance occur during data acquisition. Intelligent autodilution can also help to free up operator time by eliminating the need to prepare individual standard solutions for calibrating the system. With online autodilution, a typical calibration curve (consisting of 3 to 5 points and covering three orders of magnitude) can be created from a single, higher concentration stock solution.

Manage Your Backgrounds!

As mentioned previously, it is important to be conscious of potential backgrounds derived from laboratory equipment and chemicals (contamination) or other samples (carry-over or cross contamination). Whereas the former can only be identified by rigorously testing all equipment and different batches of the chemicals involved, the latter requires an effective cleaning strategy in between runs to be put in place. For samples that need to be digested before analysis, a blank digestion should be performed with every batch of samples, including all steps and reagents used in the process, but no sample. This way, any potential contamination from the digestion step can be identified, traced back to its origin and rectified as far as possible, before potentially biased results need to be troubleshooted or are even reported. Table I gives an overview of common reasons why an analysis may be biased through contamination or carry-over cross-contamination.

Dilute and Shoot!

Oftentimes, a challenge is not immediately recognized upfront as only limited information is available on the sample. Sometimes, the presence of other elements not subject to quantitation can cause a range of difficulties, which are only recognized upon analyzing the sample. In such cases, the analysis often delivers confusing results for the sample itself, but also the subsequent samples may suffer from the effects of residual contamination. To identify such potential challenges caused by previously unknown samples before they cause a disruption, it is recommended to follow a few simple steps. To discover unexpected elements or challenging interferents, running a full mass scan can provide a good overview about highly concentrated matrix elements or indicate the presence of unexpected interferences. A slightly higher dilution than usual safeguards the instrument from persistent contamination. Typical interferences causing puzzling results could be of different nature to those that are normally encountered. For example, doubly charged ions can be formed if an element has a second ionization potential lower than the ionization potential of argon. In this case, ions with two positive charges are formed, which appear at half mass in the spectrum (as all mass spectrometers detect ions based on their mass to charge ratio rather than their mass). The presence of rare earth elements, predominantly neodymium (Nd), samarium (Sm), or gadolinium (Gd), create false positive results on key contaminants such as arsenic (150Nd++ and 150Sm++) and selenium (156,160Gd++ on 78,80Se+). The impact of doubly charged interferences can, in some cases, be reduced by mathematical corrections (usually within a narrow concentration range), but only triple quadrupole ICP-MS systems are capable of reliably eliminating these interferences. Several doubly charged interferences may also fall on common internal standards. For example, in presence of higher amounts of lead in the sample, 206Pb++ may influence the response of 103Rh+, a common internal standard. In this case, the interference would not create a bias on the sample itself, but instead lead to potential failure of the internal standard response, or at least an incorrect estimation of the concentration of all analytes that use 103Rh for internal standardization. Although kinetic energy discrimination (KED) is considered an effective tool for suppressing polyatomic interferences in the low and middle mass range of an ICP-MS, it becomes gradually less effective in the higher mass range because the relative size difference between an analyte and the polyatomic interference decreases. This means that low concentrations of an interfering element can create an unexpected bias. An example is the analysis of mercury, which can be interfered by tungsten through the formation of tungsten oxide, even at single digit μg/L concentrations.

Summary

It is worthwhile to take a critical look at all steps in the sample preparation protocol to assure successful, accurate, and reliable determination of elements (trace and major). Through evaluating all consumables and reagents, as well as preparing appropriate blanks and quality control (QC) checks, help to identify and troubleshoot potentially biased results.

Daniel Kutscher, Jianfeng Cui, and Cristian Cojocariu are with Thermo Fisher Scientific in Bremen, Germany. Direct correspondence to:

Articles in this issue

about 4 years ago

Catching Covid: Rapid Spectroscopic Methods Show Promiseabout 4 years ago

The Infrared Spectra of Polymers IV: Rubbersabout 4 years ago

The 2022 Emerging Leader in Atomic Spectroscopy AwardNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.