- Special Issues-06-01-2009

- Volume 0

- Issue 0

Combining Raman Spectroscopy and Differential Scanning Calorimetry

Raman spectroscopy and differential scanning calorimetry (DSC) are powerful techniques in their own right. Combining the two techniques allows one to combine the chemical and structural information of Raman with the temperature and energetic information of DSC. This allows us to develop a greater understanding of the material. Applications from polymeric and pharmaceuticals are discussed as examples of how this can help the analyst.

Raman spectroscopy and differential scanning calorimetry (DSC) are powerful techniques in their own right. Combining the two techniques allows one to combine the chemical and structural information of Raman with the temperature and energetic information of DSC. This allows us to develop a greater understanding of the material. Applications from polymeric and pharmaceuticals are discussed as examples of how this can help the analyst.

Raman spectroscopy is a powerful technique for materials characterization in its own right, having found applications in such diverse areas as polymorph identification in pharmaceuticals, crystallinity studies in polymers, and reaction monitoring. Recently, the use of Raman spectroscopy with a hot stage has become common and the applications of the technique keep expanding.

Why combine Raman spectroscopy with differential scanning calorimetry (DSC) then? DSC adds several capabilities to a combined instrument. DSC is a commonly used technique in many of the same industries as Raman spectroscopy. DSC requires extremely good temperature control and exceeds the control found on hot stages. Temperatures are extremely stable and, in double-furnace designs, isothermal performance is excellent. Because variation of a few degrees can change the form of many materials, this control and precision is important.

DSC offers other advantages as well. The primary use of DSC is to determine the precise temperature of a transition and the energy of that transition. Transition temperatures are used as indicators of changes in physicochemical properties of most polymeric and pharmaceutical materials (1). Measuring subtle shifts in these temperatures is important in tracking these properties. More importantly, the energy of these transitions is very important in understanding material properties. For example, in a polymeric material, the energy of the melting peak gives you the enthalpy of melting, which is a function of the crystallinity of the material. In pharmaceuticals, the enthalpy tells you about the type of polymorphic rearrangement you have and can be useful in determining pseudo-polymorphism.

Combining the two techniques allows one to strengthen the interpretation of the data over each technique alone. For example, Raman spectroscopy will see the conversion of one polymorphic form to another, while DSC determines the energy needed for that transition and the precise temperature at which it occurs. In addition, as double-furnace DSC controls temperature directly, it will prevent the Raman laser from causing bulk heating in the sample. As we will see, this is a significant concern.

Considerations in Making DSC–Raman Spectroscopy Work

Unfortunately, getting good data from both a Raman spectrometer and a DSC system in a combined system is not as simple as it might first appear. There are a series of trade-offs that must be made in both instrument design and data quality in any simultaneous system. So the fact that there are several significant issues in measuring Raman spectroscopy and DSC data simultaneously is not unexpected. While coupling DSC with a spectroscopic technique would allow one to gain both qualitative and quantitative information at the same time (2), there are serious problems with applying spectroscopic techniques to a sample in a DSC system. Of the possible spectroscopic techniques, one of the most promising for this application is Raman spectroscopy, as it requires neither the use of reflective techniques nor alteration of the DSC instrument to obtain a transmission spectrum (3). While DSC–Raman systems have been developed before (4–6), they had limitations due to either the use of single-furnace, heat flux DSC systems (6) where the laser pulse generates significant temperature increases or to the introduction of the Raman probe into the DSC system, damaging the thermal integrity of the DSC system. Most work was not done in a truly simultaneous system, where both the Raman and the DSC scan as a function of time. Several issues needed to be addressed to make this possible.

First, the ideal sample geometries are quite different, which leads to several problems. The DSC sample is placed in a metal pan that is several millimeters in diameter and is best presented as a thin layer on the base of the pan for optimum heat transfer, which results in weak Raman intensities when short collection times are necessary. Additionally, the quartz windows used to contain the sample will reduce the signal. Finally, the small area (typically 100 μm) from which the Raman signal is collected raises the question of whether the measurement is representative. DSC sample pans are often sealed both to maintain a good sample environment and to protect the instrument from off gassing; to obtain Raman spectra, however, the pan must be open or covered by a quartz window. Both of these choices can adversely affect the DSC performance.

A second issue is that the energy from the laser must be dissipated. This will also affect the heat flow as well as causing localized heating that may distort the DSC data. In extreme cases the laser heating may induce transitions before they occur in the rest of the sample. These problems are much worse in single–furnace, heat flux DSC than in double–furnace, power-controlled DSC. Figure 1 shows the effects of the laser-induced heat gain in the bulk sample. Use of a double-furnace DSC system greatly decreases these effects. The presence of spikes in the heat flow data caused by the laser still must be dealt with by a software method, but this is relatively easy.

Figure 1: A comparison of the induced heating in the bulk sample in double- and single-furnace DSC by the Raman laser.

Finally, the introduction of the probe into the DSC environment creates a path for heat loss from the specimen, and in the case of subambient operation, a path for moisture to get in and cause frosting. These can be addressed by proper design of the coupling system and proper choice of the purge gases used. In many cases, where subambient application is not needed, no problem is found. Heat loss at high operating temperatures is not really an issue as the black-body radiation swamps the Raman spectra at temperatures higher than 350–400 °C.

Applications of DSC–Raman Spectroscopy

Combining the two techniques allows one to apply the precise temperature control of DSC with the ability of Raman to detect the different polymorphic structures, allowing precise characterization of the material. As an example, consider the common painkiller acetaminophen. Raman spectroscopy has identified the three solid-state forms of this material found under these experimental conditions. (There is a fourth form not seen here.) Combining this technique with DSC allows precise measurement of the temperatures at which they occur. Figure 2 shows the DSC run on a sample of acetaminophen. The thermogram shows two exothermic events believed to correspond to polymorphic changes in the material as well as the endothermic melt. When DSC–Raman is done, the Raman spectra shows first the conversion to a different polymorph associated with a large exothermic event below 100 °C and then another conversion to a third polymorphic form with a smaller exothermic event as seen in Figure 2. This greatly simplifies the understanding of the thermal behavior of the material and is much more conclusive than attempting to draw this information out of either conventional or modulated temperature DSC or Raman spectroscopy alone.

Figure 2: Raman spectra from DSC run of acetaminophen showing overlays of Raman spectra from 1700 to 1100 cmâ1 on the thermogram from 25 °C to 200 °C.

While the transitions here are exothermic, other polymorphic materials show changes caused by the loss of water or some other solvate from the molecule that appear as endothermic transitions. While Raman spectroscopy with a hot stage might determine the changes in the material accurately, without the understanding of the thermal data and the energy of transition, it is possible for a water loss to be seen as a polymorphic rearrangement. In DSC, we could detect that this is an endothermic event and thus is suspect. Other DSC methods can then be used to clarify the issue.

Figure 3: A thermogram of PET with overlays of PCA of Raman data shows two principal components with different profiles.

In applying DSC–Raman spectroscopy to polymers, the ability to understand crystallinity is an obvious area. Semicrystalline and crystalline polymers are of great economic importance and understanding their behavior is of great concern. For example, polyethylene terephthalate (PET) that has been rapidly cooled from the melt has a considerable amorphous content, which makes it clear. On heating it undergoes a glass transition and crystallization. This example was cooled in the DSC system at 200 °C/min. The glass transition is clearly visible in the heat flow curve but is not seen in the Raman data (Figure 3). The spectral changes are relatively small, consisting of band broadening and small band shifts. The curve derived from PCA does show the crystallization and melting events, but is very noisy. The major change associated with these is broadening of the 1726 cm–1 C=O band. There are also band shifts that vary almost linearly with temperature (Figure 4). The DSC data clarify the situation by clearly showing the strong endothermic peak that corresponds to crystal formation on heating. Here we see that the reason the material is so much more crystalline before the melt than at the start of the run is the large amount of it that crystallizes during the run.

Figure 4: Band shifts in the Raman spectra of PET at selected temperatures in the DSC run.

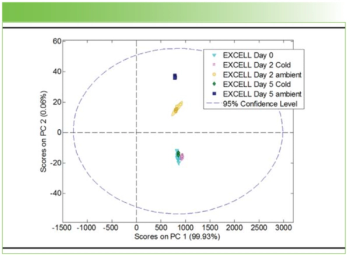

DSC–Raman can also be performed using both controlled cooling and isothermal recrystallization experiments. These approaches as well as fast-scan DSC and modulated-temperature DSC allow users to change the way the sample is heated and cooled to manipulate its properties and to trap or exclude certain transitions. In the case study described in reference 7, two PE samples, a good and a bad, were first fast heated to above their melting temperature and then cooled slowly to room temperature. All the data from each of the runs of the two samples were put into PCA models. The data were normalized to allow for differences between the samples. There is a single important PC that shows narrow bands from the crystalline phase and broad bands from the amorphous (Figure 5). The scores for the two samples show crystallization for both samples. For the controlled cooling, the scores plots for heating and cooling of the two samples are very similar. The top two pictures are taken directly from the PCA program. The noise levels in the plots are too high for any major differences to be seen, but the general shape of the curves suggests that the bad material is faster at crystallizing (Figure 6). The associated DSC runs show that the material gives a distinct crystallization peak on cooling and small differences are noted here that were not as apparent in the Raman spectra. These are very small, however, and a more aggressive type of cooling was then used to enhance these differences.

Figure 5: The PCA analysis and the bands associated with crystalline and amorphous structure in polyethylene.

For the isothermal studies, the samples were heated to above the melt as before, but then were cooled at 200 °C/min to a temperature at which polyethylene was known to recrystallize. The Raman spectrometer can collect data during the rapid heating of the material to the melt — although the fast heating will limit the number of spectra collected — and then on both the cooling and isothermal hold stages.

Figure 6: PCA scores for good and bad material.

After this experiment, the data are more conclusive in the Raman system as well as in the DSC system. The scores for the two samples show crystallization for both samples. For the starting materials and the high temperature form, the scores are similar for both samples (Figure 7). After the recrystallization, it appears that the degree of crystallization is greater for the "bad" sample than for the "good." The final spectra clearly show that the bad sample ends up more crystalline. The sharp bands are stronger relative to the broad bands from the amorphous material. Taking the melt as a starting point, we obtain a value of about 50% more amorphous in the good, confirmed by subtraction of the melt spectrum from the final spectra of each. There is an isolated band from crystalline material at 1125 cm–1 that can be used to normalize between the two samples. The normalization limits quantitative interpretation, but on a relative scale it appears that the final crystalline content of the good material is approximately 30% lower than the bad. In addition, the material recrystallizes faster, as seen in Figure 7.

Figure 7: Thermograms for the isothermal recrystallization of good (red) and bad (blue) PE samples. The double peak at the beginning is the transient associated with the instrument reaching isothermal status.

Looking at the enthalpy of crystallization, we find that the bad material has a higher value of –71.00 mJ/g, while the good is much lower at –44.96 mJ/g. This gives us roughly a 35% difference in crystallinity between the two materials. Interestingly, neither sample comes close to the crystallinity of the material at the start. Some of this is probably due to orientation in the material, but a large part is due to higher cooling rates used in making the films that were used here. Together, the DSC and Raman data explain that the problems with the bad sample are due to the material responding differently to cooling and becoming more crystalline.

Conclusions

DSC–Raman spectroscopy is a powerful tool for gaining greater understanding of material behavior, whether it is a polymer or pharmaceutical. Combining Raman spectroscopy's ability to elucidate chemical and structural information with DSC's precise measurement of temperatures and the energy of events allows us to gain a fuller picture of how a material behaves.

Kevin P. Menard is with PerkinElmer, Inc., Shelton, Connecticut. Richard Spragg is with PerkinElmer, Inc., Chalfont Road, Seer Green, Bucks, UK.

References

(1) K. Menard, "Temperature Transitions in Polymers," in W. Brostow, Ed., Performance of Plastics (HanserGardner, Cincinnati, Ohio, 2000).

(2) R. Alexander, A. Dennis, and R. Spragg, Proceeding of FACCS, September 214 (2008).

(3) R. Alexander, K. Menard, R. Spragg, and P. Ye, Proceedings of the NATAS Conference 27, 131 (2008).

(4) J. Sprunt and U. Jayasooriya, Appl. Spectrosc. 51, 1410–1414 (1997).

(5) M. Harju, J. Valkenon, and U. Jaysooriya, Spectrochim. Acta, Part A 47A, 1395–1399 (1997).

(6) J. Kauffman, L. Batykefer, D. Tuschel, and A. Bangalore, J. Pharm. Biomed. Anal., in press.

(7) K. Menard et al, Proceeding of the Polyolefin RETEC, 17, 86 (2009).

Articles in this issue

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.