- Special Issues-06-01-2009

- Volume 0

- Issue 0

Low-Resolution Raman Spectroscopy, the Photonic Engine Behind Materials Identification's Promising Future

Miniature spectrometers revolutionized the spectroscopy market more than 15 years ago and became a key factor in the creation and steady growth of the photonics field. Today these spectrometers are becoming an important part of the new market of field-deployable analytical instruments used for materials identification based on Raman spectroscopy. Just as before, these spectrometric photonic engines are key factors on reducing the cost and improving the flexibility of applications of a traditionally expensive and rigid vibrational spectroscopy method. Raman spectroscopy is becoming an affordable tool used for applications ranging from homeland security to green energy research and development, either at a laboratory, a crime scene, or a biodiesel manufacturing facility.

Miniature spectrometers revolutionized the spectroscopy market more than 15 years ago and became a key factor in the creation and steady growth of the photonics field. Today these spectrometers are becoming an important part of the new market of field-deployable analytical instruments used for materials identification based on Raman spectroscopy. Just as before, these spectrometric photonic engines are key factors on reducing the cost and improving the flexibility of applications of a traditionally expensive and rigid vibrational spectroscopy method. Raman spectroscopy is becoming an affordable tool used for applications ranging from homeland security to green energy research and development, either at a laboratory, a crime scene, or a biodiesel manufacturing facility.

The current market for analytical instruments is considered a mature market except for some important incremental innovations made to commonly used techniques and applications. In the last 15 years the high expense of trained personnel and the cost of equipment and consumables have forced the analytical instrumentation market to migrate from the laboratory testing and control traditional arrangement out to the manufacturing plant's floor with on-line analysis for process control. Fourier-transform infrared (FT-IR) and near-IR (NIR) on-line instruments are common in industry for on-line applications. To fulfill the process control requirements, these techniques developed from high-cost, complicated laboratory instruments to low-cost, easy-to-install apparatuses. This situation created a niche market highly exploited by the advent of miniature optical fiber-based spectroscopy. Important companies emerged by applying this technology to other spectroscopic techniques such as the UV–vis and fluorescence spectroscopy that are now used for all kinds of on-line analysis for chemical and other manufacturing processes. The miniature spectrometer manufacturers serve a broad range of customers for a number of optical sensing applications. These spectrometers have been used in space, water, and research laboratories, for medical analysis, atop forest canopies, and alongside active volcanoes, among many other applications. Included in these different applications, the fiber optic–based spectrometers original equipment manufacturers (OEM) markets include important sectors such as R&D, education, consumer electronics, process control, environmental monitoring, life sciences, and medical diagnostics.

Figure 1: Miniature fiber optics spectroscopy can be used to detect biological threats in crops and food supply.

Today's enterprises operate in a complex, dynamic, and global world, exposed to influences beyond their control as recently shown by the global financial crisis. This macro environment of social, economic, political, and technological forces constrains all industries and dictates the direction of its growth.

The miniature spectroscopy fiber-optics main markets include the photonics and chemical analysis fields of visible and vibrational spectroscopy. The groundbreaking invention of miniature fiber-optic spectrometers started a seemingly endless field of cost-effective R&D and educational applications. More important, it created a new market for low-cost modular spectrometers that has allowed for the sale of more than 150,000 systems in less than 20 years. The relentless growth rate of this novel industry created a business culture highly focused on certain market niches generating high profit margins and quickly generating aggressive competition.

The innovative energy of this new market has taken this technology into numerous undertakings over the past several years, becoming the industry optical engine of novel analytical techniques such as fiber optics–based oxygen sensors and laser-induced breakdown spectroscopy and now is starting to propel the low-resolution Raman spectroscopy (LRRS) applications markets. This highly accelerated market growth created a competitive advantage in the eyes of an important analytical instruments manufacturers segment eager for low-cost instrumentation, applications flexibility, and high technical support requirements. These advantages rapidly generated a secondary market for OEM applications that today encompass at least 25% of the overall miniature spectroscopy market.

Figure 2: Portable materials identification systems are currently used to analyze powder or liquid powders for forensic, homeland security, and food tampering applications such as the latest one of milk tampering with melamine.

In 2010, the U.S. spectroscopy market is expected to be $5.2 billion, increasing at an average annual growth rate of 8%, with the fastest growing sectors being mass spectrometry. Molecular spectroscopy, which encompasses the aforementioned miniature spectroscopy sector, and that which consists of infrared, ultraviolet, visible, Raman, nuclear, and electron spin resonance spectroscopy, will reach $1.7 billion at an average growth rate of 7%. The Raman spectroscopy growth rate is expected to be close to 10%.

The emergence of global terrorism has created concerns for the entire world, as well as for the United States Department of Homeland Security. Spectrometers have been used to detect terrorist threats from airports to seaports and in field applications. Increased security concerns create more opportunities for the optical instruments industry and will most certainly accelerate the growth of the miniature spectroscopy field, directly and by the creation of new OEM opportunities thanks to the flexibility and portability of these instruments.

Miniature spectrometers provide important information in fields that can go from emission spectroscopy, to find poisonous lead in toys, to fluorescence spectroscopy used to determine the presence of insecticides or unwanted chemicals on crops to determine optimal harvest time. These "photonic engines" are the foundation of handheld spectrometers, process control systems or stand-alone units for materials analysis, chemicals identification, optical sensors, and other innovative devices. The fiber optic–based spectrometers are capable of detecting spectral information ranging from 150 to 2500 nm or more by properly designing the optical bench and selecting the best available detectors. Latest designs can provide the users with resolutions as good as 0.02 nm.

Figure 3: A handheld chemical identification system is used for the detection of illegal drugs in alcoholic beverages.

The main challenge for the use of LRRS comes from its fast growth pace since all the Raman spectroscopy done in the past required costly equipment and experienced spectroscopists. Raman spectroscopy as an analytical technique cannot be deployed in field applications if the user requires extensive training or college degrees since the cost advantage of the small instruments will be lost by the manpower cost and overhead required for such deployment.

The new generation of LRRS is being exploited by large OEMs that include leaders in the health and safety industry and that include well-known names such as GE and Smiths.

These applications utilize Raman spectroscopy as the "optical engine" in what they call materials analyzers or chemical detectors. These analyzers or detectors provide rapid, non-invasive, nondestructive chemical analysis of aqueous solutions, powders, tablets, gels, and surfaces. These compact, portable instruments can detect and identify chemicals, explosives, and their components through glass and plastic containers, making them ideal for law enforcement screening and forensic applications.

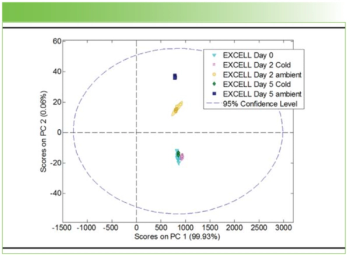

A good example of the use of Raman as a bioterrorism prevention tool includes its use in the development of instruments and methods that can not only identify dangerous spores and bacteria but also identify and differentiate less dangerous but very similar microorganisms or materials in order to eliminate unnecessary alarms and evacuations (1). These applications surged from the need for new methods to allow a fast and reagent-less differentiation of such microorganisms.

Another interesting application of LRRS includes its use in the development of instruments used in the medical field, with applications ranging from cancer detection to urea monitoring in dialysis machines (2). In the forensic field the applications and use for LRRS can go from the identification of inks and paints used in document counterfeiting to the detection of illegal drugs dissolved in liquids such as alcoholic beverages to smuggle the drugs across borders or to "spike" beverages to commit a crime by drugging victims (3).

These simple-to-use systems are actually complicated instruments designed by Raman spectroscopy experts that provide a value-added solution that includes complete understanding of the advantages and challenges that the technique presents for the specific application. These engineers and scientists must use proper analytical method development techniques to generate an application that is accurate, repeatable, and dependable. Depending on the final application, the system must fulfill all kinds of requirements that are not only scientific but legal and operational as well. If the Raman spectrometer will be used to analyze raw materials or differentiate polymorphs in the pharmaceutical industry, the method development should comply with official guideines and regulation dictated by government agencies such as the FDA. When using these instruments in forensic applications related to the identification of illegal drugs, special permits and protocols are required to obtain samples in order to generate libraries and chemometric methods of analysis of the pure illegal compounds and their possible combinations with household chemicals used to dilute the power and increase the value of the drugs in the street. In the same fashion, homeland security applications require not only the same kinds of permits to obtain explosive materials or their precursors, but also need special laboratories and installations to obtain the required spectra under safety regulations. As with any other analytical method development, the design of the required libraries and algorithms required for a successful application includes adevelopment plan, an application background, samples, testing, writing standard operating procedure, validation of the procedure, calibration requirements, chemometric modeling, peak searching protocol software, and definition of the application's analytical capabilities and implementation.

One of the challenges faced by the OEMs utilizing this technology arises from the unique spectrometer response function. Commercially available libraries are instrument specific and their use by different suppliers is highly limited and inaccurate. In order to solve this problem, the NIST started a valuable program to develop reference materials that can be used to correct the differences that arise from instrument to instrument response function (4).

Secondary markets will also take advantage of this new chemical identification with OEMs already working on instruments that will utilize surface-enhanced Raman spectroscopy (SERS). SERS counteracts one of Raman spectroscopy's weak points by utilizing colloidal-size particles in suspension or placed on solid substrates, greatly enhancing the signal near the surface of the small particles. This significant enhancement of the Raman effect allows small sample volumes to be analyzed with excellent sensitivity. A similar technique, tip-enhanced Raman spectroscopy (TERS) uses a fine metal tip to mimic the enhancements seen in SERS. Further developments of SERS and TERS will focus on Raman-active marker compounds used to enhance the signal of a particular chemical species, pathogen, or contaminant. These novel techniques are confined to research laboratories at this time but have a considerable drive to spin-offs for fast commercialization.

Conclusion

The synergetic combination of fiber-optic probes, low-cost miniature spectrometers, small and cost-effective diode lasers, chemometric software packages, and spectral libraries of thousands of compounds of interest is revolutionizing the market for Raman spectroscopy by providing the grounds for easy-to-use and highly flexible portable materials identification systems. This is a new market with the same growth potential that the optical engines that it utilizes had 15 years ago. It will generate thousands of new applications in all kinds of markets and it is already working its way to Mars.

Jorge Macho is with Ocean Optics, Inc., Dunedin, Florida.

References

(1) C. Mello, et al., J. Braz. Chem. Soc. 19(1), 29–34 (2008).

(2) S.K. Teh, W. Zheng, K.Y. Ho, M. Teh, K.G. Yeoh, and Z. Huang, Br. J. Cancer 98, 457–465 (2008).

(3) V.L. Brewster, H.G.M. Edwards, M.D. Hargreaves, and T. Munshi, Drug Testing and Analysis 1(1), 25–31 (2009).

Articles in this issue

over 16 years ago

Combining Raman Spectroscopy and Differential Scanning CalorimetryNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.