Near-Infrared Spectroscopy Enhances Sugar Cane Quality Analysis, Study Finds

A recent study demonstrates that near-infrared (NIR) spectroscopy can be used as a rapid, nondestructive method for accurately assessing sugar cane quality.

A recent collaborative study between the Audubon Sugar Institute and Louisiana State University (LSU) demonstrated the potential of near-infrared (NIR) spectroscopy to analyze the quality of sugar cane. In this study, led by Kevin McPeak of LSU, the researchers used NIR spectroscopy to test whether it can analyze sugar cane despite the presence of extraneous matter (EM) (1). The findings have significant implications for the global sugar industry, which is valued at approximately $78 billion annually (1).

The state of Louisiana is one of the largest exporters of sugar cane in the United States. Contributing approximately $2 billion to the state economy, sugar cane has been an important industry for Louisiana residents ever since Jesuit priests introduced the crop to the state back in 1751 (2). However, despite the success of the sugar cane industry in Louisiana, challenges remain. One of these challenges are diseases that can harm sugar cane crops. Some of these diseases include ratoon stunting disease (RSD) (2). Pests also can threaten sugar cane crops, requiring the use of insecticides to keep them at bay.

Currently, the industry is looking to improve and quicken the assessment of sugar cane quality. Traditional techniques used for this purpose are time-consuming and labor-intensive (1). For context, each sample can take 2–3 hours to analyze, and not every truckload of cane is tested, leading to potential discrepancies in grower payments (1). The authors of the study also acknowledge that changing climate patterns have also resulted in sugar cane being increasingly harvested with more EM, which includes soil, green and brown leaves, roots, and tops (1). This extraneous material complicates conventional analysis techniques, increasing the need for a more efficient alternative.

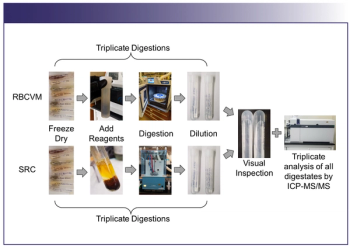

The researchers investigated whether NIR spectroscopy can accurately test sugar cane despite the presence of EM. McPeak and his team collected samples from three Louisiana sugar factories, analyzing shredded cane, pressed cane, and pressed juice. Using partial least squares regression (PLSR) models with k-fold cross-validation, the team correlated NIR spectra with reference values, identifying the most effective sample types for quality prediction (1).

The results demonstrated that pressed juice and pressed cane samples yielded the most accurate predictions of Brix (refractometric dissolved solids), pol (sucrose content by polarimetry), and moisture, outperforming shredded cane samples (1). Specifically, pressed juice had the best predictive accuracy for Brix and pol, while pressed cane offered the most reliable moisture content readings (1). These findings show the practical application of NIR spectroscopy in streamlining sugar cane quality assessments, particularly in regions experiencing increased EM because of changes in the environment.

McPeak and his team used Fourier transform–NIR (FT-NIR) spectrometers in their work, with each sample being scanned 128 times. These scans were then averaged to produce a single spectrum, with this process repeated five times per sample (1). Shredded cane and pressed cane samples were divided into five subsamples, while pressed juice samples were mixed between each scan to ensure uniformity. The spectra were then analyzed using OPUS Spectroscopy software, integrated with the Bruker FT-NIR spectrometers, to develop calibration models for Brix, pol, and moisture prediction (1).

Preprocessing techniques, such as vector normalization and first derivative methods, were used to improve predictive accuracy. The study also explored the impact of fiber size reduction, achieved by blending shredded and pressed cane samples, on model performance (1). The calibration models employed a full cross-validation approach to enhance reliability (1).

Several takeaways can be drawn from this study. The researchers show that NIR spectroscopy could offer a rapid and reliable method for assessing sugar content, moisture, and other critical parameters, NIR spectroscopy reduces reliance on labor-intensive wet chemistry techniques (1). However, the accuracy of NIR models remains dependent on the precision of primary wet chemistry methods, necessitating continued refinement of these reference standards to ensure robust calibrations (1).

Future research should focus on validating these predictive models with independent sample sets and exploring advanced nonlinear calibration techniques to further improve accuracy and robustness (1). Additionally, continued investigation into the reliability of primary wet chemistry methods will be essential in enhancing the effectiveness of NIR-based quality assessments.

References

- Ordonez, S. I.; McPeak, K. M.; Eggleston, G. Rapid Analysis of Sugarcane with High Extraneous Matter by Near-Infrared Spectroscopy. ACS Agric. Sci. Technol. 2025, ASAP. DOI:

10.1021/acsagscitech.5c00021 - Gravois, K. Louisiana’s Sugarcane Industry. LSU Agriculture Center. Available at:

https://www.lsuagcenter.com/portals/communications/publications/agmag/archive/2001/fall/louisianas-sugarcane-industry#:~:text=Sugarcane%20has%20been%20an%20integral,Louisiana%20sugar%20industry%20remain%20profitable . (accessed 2025-03-31).

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.