Using LIBS to Track Uranium Materials

Laser induced breakdown spectroscopy (LIBS) has been applied as quantitative and qualitative analytical method for a variety of matrices. A paper published in the journal Applied Spectroscopy in 2018 (1) was chosen by from the North American Society for LIBS (NASLIBS) and the Society for Applied Spectroscopy (SAS) as the best paper on the topic of LIBS. In this paper, a molten salt aerosol–laser-induced breakdown spectroscopy (LIBS) instrument was used to measure the uranium (U) content in a ternary UCl3–LiCl–KCl salt matrix to investigate the development of a near real-time analytical method. We spoke with Ammon Williams, the primary author of this paper, who is currently with the Idaho National Laboratory (INL), about this work.

Laser induced breakdown spectroscopy (LIBS) has been applied as quantitative and qualitative analytical method for a variety of matrices. A paper published in the journal Applied Spectroscopy in 2018 (1) was chosen by from the North American Society for LIBS (NASLIBS) and the Society for Applied Spectroscopy (SAS) as the best paper on the topic of LIBS. In this paper, a molten salt aerosol–laser-induced breakdown spectroscopy (LIBS) instrument was used to measure the uranium (U) content in a ternary UCl3–LiCl–KCl salt matrix to investigate the development of a near real-time analytical method. This method development was intended to be applied for uranium material safeguards and accountability. Five different uranium concentrations were used to determine the analytical figures of merit. In the analytical development work, three uranium emission lines were used to develop univariate calibration curves; these included 367.01 nm, 385.96 nm, and 387.10 nm lines. Both univariate and multivariate calibration approaches were tested for uranium content, with a multivariate partial least squares (PLS) model achieving the optimum analytical results, with a root mean squared standard error of cross validation (RMSECV) of 0.085 weight percent. The award-winning paper concluded that the aerosol-LIBS system was capable of monitoring the uranium concentration for the normal operational uranium levels of pyroprocessing molten salts. We spoke with Ammon Williams, the primary author of this paper, who is currently with the Idaho National Laboratory (INL), about this work.

Your paper examines measuring the accumulation of special nuclear materials in molten salt during the processing of spent nuclear fuel. Why is this a concern? Why is LIBS a useful technique for this purpose?

The main concern is material accountancy of the actinides, specifically uranium and plutonium in the molten salt throughout the different processes. This, of course, is a legal requirement from the International Atomic Energy Agency (IAEA), and is good practice to ensure nuclear materials are used for peaceful purposes. The reason that this research is so important is that there are limited near-real time and in situ analytical approaches to measure actinide concentrations in the difficult hot cell environment required for electrochemical processing of spent nuclear fuel. LIBS is an attractive analytical approach for material tracking, as it can be performed remotely, quickly, and under harsh conditions. In addition, it is essentially a non-destructive technique, and, more importantly, it does not require that a physical sample be removed from the processing environment or mass balance area.

Would you explain the differences between standard LIBS sampling techniques and the molten salt aerosol–LIBS instrument that you have developed?

The LIBS aspects of both techniques are the same in that a laser pulse generates a plasma in which characteristic light is collected to generate a spectrum. The distinguishing feature is the novel approach utilized to prepare the liquid sample for LIBS analysis. In the electrorefining process being monitored, the molten salt is in a liquid form, which is difficult to sample via LIBS, due to splashing, surface perturbations, and surface layers. In the aerosol approach, the liquid salt is drawn and aerosolized prior to LIBS sampling, which reduces many of these challenges.

What are the main advantages you discovered by using a multivariate approach, rather than a univariate one? What led you to select partial least squares (PLS) over other multivariate calibration approaches?

The key advantage I found with using a multivariate approach is that it allows for more complex sample matrices. In most of the laboratory work I have done, I know what is in the sample, and can identify spectral lines that have low interferences. However, in the actual electrochemical process, the salt will contain large amounts of actinides, rare earth chlorides, and other elements that are notorious for having complex and busy spectra. In that sample matrix, it would be significantly more difficult to perform a univariate calibration than it would be to perform a multivariate calibration approach. We selected the PLS multivariate method, as it is a standard approach, and one in which we felt was suitable for our application.

Tell us a little bit about the LIBS technique you utilized to perform this task, and why you believe that was a good analytical method choice for this analysis. What particular factors did you consider in your selection of this analytical technique?

In this research, we used optical windows and mirrors to deliver the laser pulse into our glovebox (argon gas environment), and then used fiber optic feed throughs to transport the LIBS signal to an echelle spectrometer outside the glovebox. With this approach, only light was passing through the containment system. In my application, a suitable analytical technique needed to be adaptable to in situ implementation, provide timely elemental information, and require minimal sample preparation and handling. The LIBS analytical technique was highly suited for these constraints, as it can provide in situ and timely analytical information about the sample with minimal sample preparation in harsh nuclear applications (for example, high temperature, radiation, corrosive).

Is there anything that you’ve done in your study that is different from what other researchers have done as they examined the same problem?

Other research in this area focused on applying LIBS to either solid salt or the liquid surface of the salt. Both approaches have strengths and weaknesses. In this research, we approached the problem differently by applying the LIBS analysis to a molten salt aerosol.

What were the most serious challenges that you encountered while developing this approach? How did you overcome them?

The first challenging aspect was developing a method to generate molten salt aerosol droplets at extremely high temperatures and in a highly corrosive environment. This was overcome by modifying a collison-type nebulizer with appropriate materials, seals, and heating. Another serious challenge encountered was developing a sampling chamber that allowed for light into and out of the sampling stream, while preventing particle buildup on the optics. Both of those challenges, and many others, were overcome with persistence, brainstorming, and many design iterations.

Are you pleased with the results you have you achieved so far? What are your next steps in this work?

I am pleased; it was extremely challenging to develop this system, and achieving a successful result was very satisfying. Going forward, we would like to optimize the aerosol system configuration to reduce optical degradation and increase stability. In addition, we want to test the system in more complex salt matrices, including additional uranium samples with multiple rare earth elements.

What are some major gaps in knowledge in the use of LIBS that you would like to see more research and development time devoted to?

With the traditional LIBS approach, it is difficult to determine isotopic information of materials without expensive high resolution spectrometers. For nuclear material accountancy purposes, having the ability to determine the actinide isotopic information in our samples is an important goal. An emerging technique called laser ablation molecular isotope spectroscopy (LAMIS) is similar to LIBS, but gates the detector significantly later to allow for molecular recombination. In this process, isotopic shifts become greater, and the spectrometer resolution requirements can be more relaxed. I am interested in seeing more research in this area, specifically with regards to complex, mixed actinide samples, like we expect to see in nuclear safeguards applications.

What is your general approach to problem solving in your scientific work?

My research motto is: think, apply, learn, and refine.

What does receiving the NASLIBS/SAS Best Paper Award personally mean to you?

I am deeply honored to receive this award, and I appreciate the recognition for my work.

Reference

- A Williams and S. Phongikaroon, Laser-Induced Breakdown Spectroscopy (LIBS) Measurement of Uranium in Molten Salt. Appl. Spectrosc., 72(7), 1029–1039 (2018).

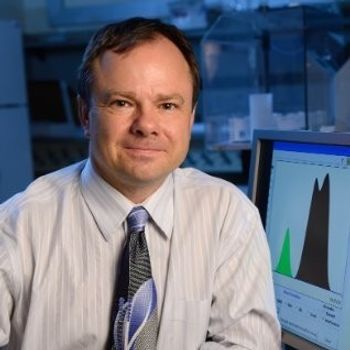

Ammon Williams received a BS degree in Mechanical Engineering in 2009 from Brigham Young University–Idaho. He then studied Chemical Engineering, and earned a MS degree in 2012 from the University of Idaho. Finally, Williams received his PhD in Mechanical and Nuclear Engineering from the Virginia Commonwealth University in 2016 for his dissertation titled, “Measurement of Rare Earth and Uranium Elements using Laser-Induced Breakdown Spectroscopy (LIBS) in an Aerosol System for Nuclear Safeguards Applications.” Since graduation, he has worked as a research scientist at the Idaho National Laboratory. Dr. Williams’s current research interest are nuclear safeguards and nonproliferation, and, more specifically, analytical techniques and approaches to monitor special nuclear materials (uranium and plutonium) in harsh and remote environments. Williams has made significant contributions in the area of molten salt LIBS, as well as other measurement approaches, such as electroanalytical and bubble level measurement techniques.

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.