- Spectroscopy-02-01-2018

- Volume 33

- Issue 2

Verification of Pharmaceutical Raw Materials Using FT-NIR Spectroscopy

FT-NIR spectroscopy can be used to overcome a range of challenges in raw material identification while also meeting the stringent requirements of regulated environments.

This investigation describes how Fourier transform near-infrared (FT-NIR) spectroscopy can be deployed using a workflow approach to overcome a range of different challenges in raw material identification while also meeting the stringent requirements of regulated environments.

Modern near-infrared (NIR) spectroscopy instrumentation and its interchangeable sampling modules offer a great deal of versatility to handle the diverse range of solid, liquid, and gel-based raw materials encountered at various stages of the pharmaceutical manufacturing process. Rapid characterization of a material by its NIR spectrum can be achieved by comparison against a series of reference spectra, which allows for unambiguous identification of the raw material, and discrimination from other similar compounds.

This investigation describes how Fourier transform (FT)-NIR spectroscopy can be deployed using a workflow approach to overcome a range of different challenges in raw material identification while also meeting the stringent requirements of regulated environments. No sample preparation or dilution is required, and the measurements can be performed directly through glass vials or Petri dishes using an NIR reflectance sampling accessory.

Principles of NIR

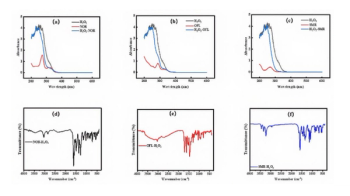

The NIR spectral bands of raw materials are caused by the combination and overtone bands derived from the fundamental vibrations in the mid-infrared (IR) region of the spectrum, and are often unique fingerprints for that material. Spectra of three typical raw materials used in the pharmaceutical industry are shown in Figure 1.

Figure 1: Typical NIR spectra of pharmaceutical raw materials: diclofenac (black), poloxamer (red), and talc (blue).

Choice of Algorithms

These spectra allow for the identification of the material by comparison against a series of reference spectra using appropriate decision-making algorithms, based on the complexity of the analysis. Many standard raw material identification methods use a simple spectral correlation algorithm, which will measure the correlation of an unknown spectrum against a series of reference spectra and report the closest material to the unknown (1). For example, a score of 1 is a perfect match, whereas a score of 0 shows no correlation between the sample and reference spectra. When analyzing materials, it is therefore important that the analysis is focusing on the spectral features of the materials. However, when using this method problems can arise calculating the similarity of spectra when encountering

- reproducibility of sampling errors (such as those associated with repacking of solid powdered sample),

- varying baselines, and

- non-uniform noise distribution.

These effects can be decreased by using a number of mathematical filters that reduce the contribution where the information tends to be unreliable. The net result of these filters is to enhance material-specific spectral features while minimizing spectral contributions related to instrument, sampling, and atmospheric conditions.

These methods allow pass–fail thresholds based on both correlation with the reference materials and discrimination from the second-best matches in the reference materials, ensuring that the correct material is identified and no false positives are obtained from other reference materials.

Another algorithm is soft independent modeling class analogies (SIMCA), which is a chemometric approach that models the variation within the collection of reference spectra for a given material as well as the difference between spectra of different materials (2). This algorithm helps overcome the issues described above. This capability allows SIMCA to be sensitive to small spectral differences produced by impurities, even in the presence of normal batch-to-batch or sampling variations. For ease of implementation, either of these algorithms is typically deployed using a workflow approach through the system software of the spectrometer.

Experimental

To show the practical implementation of these two algorithms, experiments were performed representing the typical challenges encountered in raw material identification measurements. The instrument used for this investigation was the Spectrum Two N FT-NIR spectrometer and its NIR reflectance module (PerkinElmer Inc.). The system's software was used for data modeling, troubleshooting, and method validation. The system includes workflow software for combining data collection, analysis, and reporting into simple software routines, with an enhanced security option, for assistance when working in a regulated environment.

The three experiments, which require a different algorithmic approach to the data analysis, are described below.

Experiment 1

NIR Spectra of 34 chemically different solid raw materials were measured. The raw material "library" contained a small number of active ingredients, and the remainder were excipients. Since these materials are chemically different, their NIR spectra should be sufficiently different to allow easy identification of the material using the COMPARE algorithm supplied with the spectrometer.

Experiment 2

Spectra of seven different grades of Avicel (FMC), a microcrystalline cellulose compound used as an excipient, were measured. Since all of these materials are chemically the same, but varied in physical properties, a more powerful algorithm, SIMCA, was used to discriminate the materials.

Experiment 3

Identification of an unexpected failure material. In cases where a material fails the raw material identification, further investigative analysis is required using library searching against commercial spectral libraries.

Instrumental Conditions

The operating conditions for all three experiments are shown in Table I.

Results

Experiment 1: Raw Material Identification

NIR reflectance spectra were collected for a series of 34 different powdered raw materials to be used as a reference spectra library for the raw material identification method using the COMPARE algorithm. A series of nine independent validation spectra were collected consisting of three samples of povidone from different batches, three samples of Avicel from different batches, and one sample each of calcium ascorbate, hydroxypropyl methyl cellulose (HPMC), and magnesium stearate. These validation samples were obtained from different suppliers to the original reference set. Spectra of these five very different material types are shown in Figure 2.

Figure 2: Spectra of validation materials: Avicel (black), povidone (red), calcium ascorbate (blue), HPMC (purple), and magnesium stearate (green).

The pass–fail criteria were set to a correlation value of 0.98 and a discrimination value of 0.05. All of the materials exceeded the correlation and discrimination thresholds and were therefore classed as pass materials. This is demonstrated in Table II.

Table II: Comparison of results for validation materials

Since the raw materials are chemically very different, their NIR spectra, combined with the COMPARE algorithms, were easily capable of identifying the materials.

Further method validation was performed for the Avicel using three batches of the same grade of Avicel PH103. A sample from each batch was placed in a glass vial. Each glass vial was then measured in triplicate shaking the sample in the vial and replacing it on the NIR reflectance module. These nine measurements, with statistical data analysis, are shown in Table III.

Experiment 2: Discrimination of Closely Related Materials

Avicel PH is a microcrystalline cellulose product with the PH designating that it is suitable for pharmaceutical use. It has excellent compressibility and is used for tablet compression and also for wet granulation. There are several different grades of Avicel PH that differ mainly in particle size and moisture content. Therefore, the correct choice of the right grade is essential to achieve the right compressibility required for making a tablet or low moisture content for use with moisture-sensitive active ingredients. Since the Avicel materials are all the same chemical compound, their NIR spectra are almost identical making it difficult to easily discriminate the different grades. However, NIR spectra are affected by particle size and spectral features because of moisture observed.

The NIR spectra of a series of samples with different Avicel PH grades were used to develop a SIMCA model to allow confirmation of the grade of Avicel raw materials. Three samples were taken for each of the following grades of Avicel: PH101, PH102, PH103, PH105, PH113, PH301, and PH302. For each of the three samples, triplicate measurements were made on the NIR reflectance module, representing nine spectra per grade and a total of 63 total spectra for the seven grades. The spectra of all the samples are shown in Figure 3.

Figure 3: Spectra of Avicel samples.

The COMPARE algorithm correctly identified all of the materials as Avicel. However, it was not able to discriminate between the different grades with all grades exceeding the pass–fail correlation limit. SIMCA uses a chemometric approach to spectral modeling and is capable of accounting not only for the differences between different materials, but also for the variability within the same material because of batch differences. The 63 spectra of the Avicel samples were input into a SIMCA method to try to separate out the different grades of materials, and the resulting score plot is shown in Figure 4.

Figure 4: Principal component scores plot showing separation of Avicel grades.

Each of the spheres in the plot represents the data from each of the Avicel grades; the further apart the spheres (larger intermaterial distance), the better the chance of discrimination. A Coomans plot, as shown in Figure 5, shows the model distances between two classes of material-in this case, Avicel PH101 and PH102 exhibit clear separation. In this model, there are no overlaps between the grades, inferring that there is less chance of misclassification.

Figure 5: Coomans plot showing separation of classes of materials.

This experiment demonstrates the power of the SIMCA algorithm, which is capable of distinguishing between chemically identical substances having different physical properties. In this example, SIMCA successfully separated seven different grades of Avicel in which the grades differed only in particle size and moisture content. The COMPARE algorithm was capable of correctly identifying the samples as Avicel, but was unsuccessful at distinguishing between the different grades.

Experiment 3: Identification of an Unexpected Failure Material

Occasionally, an NIR raw material analysis can result in a failure requiring further investigation. This can occur, for example, when a new supplier is selected for a particular raw material or, in extreme cases, where the wrong material has been supplied. Fortunately, this is a rare occurrence, but it requires further investigation and correct identification of the suspect material. Commercially available pharmaceutical NIR spectral libraries are available containing more than 1300 spectra of excipients, drugs and active substances, and other supporting chemicals used in the industry. Using these spectral libraries, together with an optimized search algorithm, allows for the seamless identification of unknown materials.

An unlabeled powder material was tested in a glass vial using the NIR Reflectance Module. The NIR spectrum collected was tested using the COMPARE set of 34 reference standards described previously. The sample failed the COMPARE analysis with the best hit being dextrose with a score of approximately 0.48, well below the acceptance threshold of 0.98. This is exemplified in Figure 6, which shows the unlabeled powder spectrum (black), compared to the best hits dextrose (red) and Avicel (green).

Figure 6: COMPARE algorithm results for the suspect sample (black), compared with the best hits dextrose (red) and Avicel (green).

The same spectrum was then analyzed using the Search algorithm comparing the unknown against the NIR pharma spectral database from ST Japan (3), containing 1340 spectra. Using the Search algorithm, the material was correctly identified as D-mannitol with a Search score of 0.99. This is exemplified in Figure 7, which shows the spectrum for the unknown sample (black) and the D-mannitol (red).

Figure 7: Search result identifying the suspect material (black) as D-mannitol (red).

Conclusion

NIR spectroscopy has proven to be a fast and easy technique in the pharmaceutical industry for raw material identification. Materials can be measured within seconds using sampling techniques, such as NIR reflectance in glass vials, which require no sample preparation. NIR spectra are specific to the material being analyzed, allowing samples to be tested against databases of standard reference spectra. A choice of algorithms is available for routine identification of chemically different materials, advanced analysis of very similar materials, and identification of unknown materials. All of these approaches can be integrated into a workflow approach to both increase productivity of analysis and reproducibility of results.

References

(1) National Cancer Institute, Division of Cancer Treatment and Diagnostics, COMPARE Analysis:

(2) S. Wold and M. Sjostrom, in Chemometrics Theory and Application, B.R. Kowalski, Ed. (ACS Symposium Series 52, Washington, D.C., American Chemical Society, 1977), pp. 243–282.

(3) S.T. Japan Spectral Libraries,

Ian Robertson and Jerry Sellors are with PerkinElmer Inc., in Seer Green, UK. Direct correspondence to:

Articles in this issue

almost 8 years ago

Use of 2D COS to Tease Out Structural Information on Polymersalmost 8 years ago

Outliers, Part II: Pitfalls in Detecting Outliersalmost 8 years ago

Market Profile: Elemental Analyzersalmost 8 years ago

Vol 33 No 2 Spectroscopy February 2018 Regular Issue PDFNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.

![Figure 3: Plots of lg[(F0-F)/F] vs. lg[Q] of ZNF191(243-368) by DNA.](https://cdn.sanity.io/images/0vv8moc6/spectroscopy/a1aa032a5c8b165ac1a84e997ece7c4311d5322d-620x432.png?w=350&fit=crop&auto=format)