- Special Issues-12-01-2014

- Volume 29

- Issue 12

Closed Vessel Digestion of Frosting or Icing Using SRC Technology

Milestone's UltraWAVE microwave digestion system with its groundbreaking single reaction chamber (SRC) technology enables the simultaneous digestion of up of to 22 different food sample types with different chemistries at temperatures and pressures as high as 300 °C and 200 bar, greatly increasing efficiency and simplifying product development.

Elemental impurities are monitored in foods to ensure safe levels and compliance with regulation. One particular class of these elemental impurities, the "Big 4" (arsenic, mercury, lead and cadmium), are of special concern because ingestion of quantity relatively low in food product can cause serious health issues, including - but not limited to - reproductive troubles, developmental disorder, brain damage, kidney and liver damage, and cancer. Given the serious health risks, a more stringent regulation is calling for the use of closed vessels digestion for sample preparation and inductively coupled plasma (ICP) for elemental impurities analysis as a replacement of obsolete and subjective methods of analysis based on colorimetric tests.

Summary

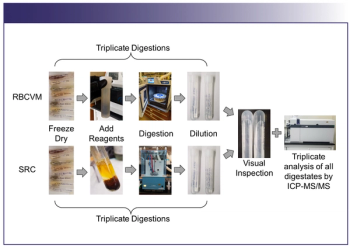

In this application note, two frosting samples are digested simultaneously on a 15-position rack with a single temperature profile. In addition, setting the instrument is straightforward: a ramp time to target temperature and a hold time at target temperature.

Frosting or icing products are delicate matrices to digest because they are made of significant amounts of carbohydrate and lipids, and thus are very exothermic during degradation. Digestion of the two varieties of frosting using a traditional microwave system would require two different runs and could possibly require two different rotors. Because of the exothermic nature of the sample, on a traditional microwave there is a limitation of the size of the sample that could be digested, since a relatively large sample size (>0.500 g) will generate a level of pressure that will cause the system to vent with loss of volatile elements.

Table I: Sample and chemistry

Method Details

Samples were placed in a 15-position rack and lowered into the single reaction chamber. The chamber was pre-pressurized with nitrogen at 40 bar to raise the acids boiling point and thus prevent any cross-contamination and loss of volatiles due to boiling and spitting as the temperature increases inside the chamber.

Conclusion

The two samples were fully digested as evidenced by the clear solutions obtained. The digestion lasted for less than 1 h including cooling time. The higher performance and greater ease of use make the UltraWAVE a good fit for a food company where samples of different types are common. Additionally, by using five position vials, samples as large as 2 g can be digested. Such capability not only addresses the common sample homogeneity concern of the food industry, but also gives the possibility to dilute samples with as much flexibility for ICP-OES as for ICP-MS.

Milestone, Inc.

25 Controls Drive, Shelton, CT 06484

tel. (866) 995-5100, fax (203) 925-4241

Website:

Articles in this issue

about 11 years ago

Computer Validation: Do All Roads Lead to Annex 11?about 11 years ago

Three-Dimensional Raman Imaging of Ion-Exchanged Waveguidesabout 11 years ago

Initial Quantitative Measurements with Handheld LIBSabout 11 years ago

Characterization of Diesel Fuel Using a Modular Raman Systemabout 11 years ago

Distinguishing Release Agents on Molded Rubber Using ATR Spectroscopyabout 11 years ago

The Moxtek ICE Cube Polarizing Beamsplitterabout 11 years ago

EDAX Inc.about 11 years ago

Raman Spectroscopy for Pigment Identificationabout 11 years ago

Avantes, Inc.Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.