Article

Spectroscopy

Spectroscopy

Ultrafast Lasers in Spectroscopy—Moving into the Mainstream

Author(s):

A look at how high-powered ultrafast lasers are moving toward widespread use in spectroscopy and in industrial settings and the developments that are driving these changes

A decade ago few people would have had the fortitude to suggest that high-powered ultrafast lasers were "turnkey." Now they are moving toward widespread use in spectroscopy and in industrial settings. This is a brief look at what has changed in the past decade, what is driving the change, and some of the emerging applications that are enabled by the increasing stability and robustness of ultrafast laser sources.

For years, since its invention in 1982 by Peter Moulton at MIT Lincoln Laboratory, the workhorse of the ultrafast-laser scientific community has been the Ti:sapphire laser. Able to generate tunable light between 600–1100 nm, the Ti:sapphire laser has been used in fundamental laboratory studies involving frequency-comb spectroscopy, the generation of coherent extreme ultraviolet light, filamentation, and ultrafast laser–material interaction-to name just a few areas of potential interest to readers of this magazine. Initial work on the optical frequency comb technique, for which John Hall and Theodor Hänsch shared one half of the 2005 Nobel Prize in Physics, depended heavily on Ti:sapphire lasers for the generation of the comb.

The usefulness of the Ti:sapphire laser extends into present work on attosecond (1/1000 of a femtosecond) lasers, in which the Ti:sapphire is used as a pump for molecular interactions generating the final pulse. However, for all its utility and history, the Ti:sapphire laser is generally confined to the laboratory. These systems are still large, complex, and relatively expensive. Although newer models require less care and feeding, Ti:sapphire lasers have always been somewhat difficult to keep stable under changing conditions, requiring a trained operator for stable operation over relatively long periods of time. They are sensitive to temperature and vibration, and therefore are not useful for industrial or mobile applications.

Development of Ultrafast Fiber Lasers

The telecommunications revolution in the late 1990s and early 2000s led to substantial advances in fiber lasers, in which the gain medium (typically ytterbium, erbium, or thulium) is doped into the fiber. These lasers operate around 1-, 1.5-, and 2-µm wavelengths, respectively. Because all of the gain is in the fiber, and various parts of the laser are coupled with small optical components, the entire system can be made compact and light, with the fiber coil typically defining the limiting dimensions. With the absence of bulk optical elements, ultrafast fiber lasers are much more tolerant of harsh environments. They can be pumped by compact, low-power, and relatively inexpensive and stable laser diodes that are themselves rugged. No beam alignment (or misalignment) occurs, and in general they open up a variety of new operating environments for ultrafast lasers.

These considerations have driven down the cost and widened the scope of ultrafast lasers. However, considerable development has occurred in the last decade to bring fiber lasers to the current state of the art. In particular, work on maintenance of the polarization and dispersion of the light as it circulates in the fiber cavity has been extensive. The typical dispersion in fiber delays short wavelength light more than longer wavelength light, causing stretching of the frequency components of the pulse as it runs through the fiber. The primary methods to control dispersion use fiber with a configured anomalous dispersion profile, in which slowing of light near absorption bands in the glass reverse this phenomena, delaying the longer wavelength light and recompressing the frequencies in a pulse.

Still other improvements have improved the performance of ultrafast fiber lasers for particular applications. Laser pulse width can be flexibly controlled by, for example, intracavity fiber Bragg gratings or similar filters. Programmable spatial light modulators are able to cast various shapes, such as multiple spots, lines, and characters onto surfaces, allowing tailored ablation or laser-matter interactions. Improved fibers and pulse control have resulted in increasingly impressive beam qualities, with M2 values as good as 1.3. This indication of the effective divergence of the beam after it exits the fiber means that these ultrafast pulses can propagate in free space for a substantial distance, and focusing qualities will be quite good.

For purposes of comparison, Table I illustrates typical specifications for laboratory Ti:sapphire lasers and ultrafast fiber lasers.

Table I: Typical parameters for Ti:sapphire and ultrafast fiber lasers

What Applications Are Enabled by Ultrafast Lasers?

Ultrafast lasers have a wide array of applications, and as the technology and features improve, the list keeps increasing. Here, we cover a few of the more interesting applications, and some of the higher-volume applications in particular. Each of these topics likely deserves a column of its own, but the treatment here is necessarily abbreviated.

Laser Micromachining

Laser micromachining and material processing is certainly one of the highest-volume uses of lasers. The benefit of using an ultrafast laser for micromachining is that femtosecond pulses interact in a fundamentally different way with material than do their slower nanosecond, and to a great extent, picosecond cousins. The two physical effects of greatest importance are interrelated (1).

The first key difference between material interaction with ultrafast and slower lasers is that femtosecond pulses are much faster than the lattice vibration time (1012–1013 Hz) in solids. Because the entire laser pulse occurs much faster than the molecular motion in the structure, no phonons are excited by the laser pulse directly. As a consequence, there is little or no heating of the sample during the laser pulse. Electrons in the material are the only things moving at the timescale of the laser pulse, and the high intensity of the femtosecond pulses causes multiphoton ionization and a cascade of events leading to rapid material removal without substantial heating. In contrast, during ablation with nanosecond pulses, there is substantial material heating. Melting and other physical processes associated with nanosecond pulses yield craters that are much less controlled, and much larger in damage area for the same spot size, compared with ultrafast-laser craters, which typically look as if the material was cleanly removed by a punch, with smooth sides.

Second, the extremely high fluence of the femtosecond laser pulse allows processing of essentially any material type, including transparent materials. With slower pulses, the photon absorption into a transparent material is typically inversely proportional to the wavelength of light. This advantage led to the early adoption of excimer lasers, with nanosecond pulses and wavelengths at 193 nm and 248 nm, for ablation of materials such as optical glass. These applications persist, but increasingly femtosecond lasers are supplanting excimers as the former become more and more reliable. Because of the mechanism of multiphoton ionization as the initiation to the ablation event, ultrafast lasers in the 1- and 1.5-µm wavelength ranges are absorbed well, even by transparent materials such as glasses.

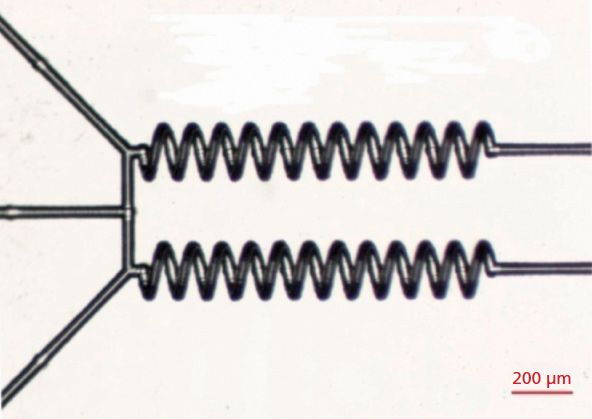

As an example, Figure 1 illustrates a multichannel helical mixer with three inlets and two outlets from reference 2. This mixer was made in fused silica using an 800-nm laser with a 50-fs pulse. Fused silica is one of the more difficult ablation targets for nanosecond-class lasers. A programmable three-axis stage was used to guide the laser focus through the fused silica. The helical microchannel has 12 turns in a length of 1200 µm, with a diameter of 150 µm. The cross-section of the flow is 35 ± 1 µm; the authors say that the error in the dimensions of any of the structures can be controlled to 1–2 µm. Following laser ablation, a multistage etch in hydrofluoric acid produces the structure, which is encapsulated in a polydimethylsiloxane film so that it can be connected to the rest of the process.

Figure 1: A multichannel mixer produced by femtosecond laser ablation in fused silica, observed under an optical microscope. Adapted from reference 2. Reprinted under Creative Commons 4.0 Open Access license.

Terahertz Imaging and Spectroscopy

Terahertz radiation (also known as submillimeter radiation) is able to pass through a number of opaque materials, particularly nonpolar, nonconductive materials such as textiles, paper, and many plastics. In addition, terahertz radiation, defined as 0.3 to 3 THz, or sometimes more broadly as 0.1 to 10 THz, is non-ionizing, so it is generally safe for humans. Terahertz radiation corresponds to the energy of low-lying ro-vibrational transitions and molecular deformations. Terahertz spectroscopy has uses in security (detection of explosives), medical imaging (3), and numerous other applications. Also, terahertz radiation is highly absorbed by water, making the method sensitive to the density of living tissue. The molecule-specific fingerprint of many complex molecules is unique, and thus there is a high potential for terahertz spectroscopy to find differentiated applications. Compared to microwaves, terahertz waves are much shorter, providing better spatial resolution given the diffraction limit. Unfortunately, terahertz radiation is not as easy to generate as microwaves are.

One of the issues for terahertz spectroscopy is that there are few sources that generate light in this range, particularly coherent light. Commercial quantum cascade lasers can provide continuous tunable power at the 1–10 mW level, which is useful for absorption spectroscopy. Higher powers, in the 250-mW range, have been achieved in several laboratories. These devices operate at cryogenic temperatures and are somewhat complex and may be difficult to field. Tuning may also be obtained by mixing two near-infrared (NIR) diode lasers that are close in frequency on a semiconductor. This can be used for high-resolution spectroscopy, but the low power output means that scanning through a large spectral range may take minutes or more.

Ultrafast lasers provide a convenient pulsed source for coherent terahertz radiation. There are multiple methods for producing terahertz radiation, essentially all of them using the ultrafast pulse (~10–250 fs) to generate a similar duration effect in a solid-state semiconductor or crystal. For example, in a photoconductive emitter, ultrafast light interacts with a biased semiconductor material, causing current to flow briefly (picoseconds) in the semiconductor. The semiconductor emits a pulse of terahertz radiation (the fast Fourier transform [FFT] of a picosecond pulse corresponds to terahertz frequencies). This radiation, typically pulsed at high frequency, can be used for illumination of a sample of interest. Terahertz time-domain spectroscopy uses two lasers (or a single laser with a beamsplitter), mixing the return signal to get amplitude and phase information.

As an example, Figure 2 illustrates the use of terahertz time-domain spectroscopy in the detection of common explosives, with data from reference 4. Explosives RDX (as a pellet), a plastic mixture of RDX, PETN, and polyethylene (which is similar to Semtex H), and a plastic mixture of RDX and polyethylene (which is similar to C4) were each covered with a thin polyethylene sheet and a piece of paper. Additionally, a sample of RDX powder was covered with the polyethylene sheet. Terahertz reflectance spectra were collected and processed using the method detailed in the paper. Obviously strong signals are collected from each of the explosives, and all of the explosives could be differentiated from each other.

Figure 2: Reflected terahertz signal from common explosives covered with a polyethylene sheet or a piece of paper. Adapted from reference 4. Reprinted under Creative Commons 4.0 Open Access license.

Laser Eye Surgery

In the decades since laser-assisted in situ keratomileusis (LASIK) surgery was popularized to reshape the cornea and correct vision, excimer lasers have been the mainstay of the practice. One of the larger concerns that patients have with this procedure has typically been the use of a microblade called a microkeratome to cut the covering of the cornea, exposing the corneal tissue for resurfacing using the excimer laser. Recently, femtosecond lasers have been used to precisely create the cut and avoid use of the microkeratome in the procedure. This so-called "bladeless" LASIK has been in common practice for more than a decade (5).

Following this success, femtosecond lasers are now routinely used in cataract surgery. In such surgery, a similar incision is made in the eye tissue with the femtosecond laser, and then the laser is used to fragment the clouded cornea, which is removed and replaced with a corneal replacement lens. The laser fragmentation is an improvement compared to the older method of ultrasonic fragmentation, which can lead to energy buildup and heating. The laser method both reduces heating of the eye and softens the lens, making it easier to ultimately remove (6).

Summary

Ultrafast lasers have matured in the past decade, to the point where thousands are in the field performing laser micromachining, security scans, and eye surgeries, among many prominent applications. The development of the ultrafast fiber laser has brought robustness, and years of refinement have brought features such as controllable power, beam shape, and focus. All of these have allowed femtosecond lasers to move out of the laboratory and into the world of applications.

Acknowledgment

The author would like to thank Neal Montgomery from Amplitude Systemes for his helpful discussions.

References

(1) K.C. Phillips et al., Adv. Opt. Photonics 7(4), 684–712 (2015). http://dx.doi.org/10.1364/AOP.7.000684.

(2) C. Shan et al., Micromachines 9(1), 29–36 (2018).

(3) X. Yang et al., Trends Biotechnol. 34(10), 810–824 (2016). https://doi.org/10.1016/j.tibtech.2016.04.008.

(4) N. Palka, Opt. Eng. 53(3), (2013). http://doi:10.1117/1.OE.53.3.031202.

(5) I. Ratkay-Traub et al., Ophthalmology Clinics of North America 14(2), 347–355 (2001).

(6) K.E. Donaldson et al., J. Cataract Refractive Surg. 39(11), 1753–1763 (2013).

JSteven G. Buckley, PhD

Steven G. Buckley, PhD, is the CEO of Flash Photonics, an Affiliate Associate Professor at the University of Washington, and a consultant to the spectroscopy industry. Direct correspondence about this column to: SpectroscopyEdit@ubm.com.

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.