- The Application Notebook 09-01-2021

- Volume 36

- Issue S9

Cartesian Geometry EDXRF for Trace Analysis and Measurement of Complex Elemental Composition

Measuring trace element concentrations and complex elemental composition are essential in environmental, recycling, and industrial process control applications. For instance, compliance with regulatory norms is needed to confirm that heavy metals are below acceptable levels, reclaim valuable precious metals catalysts, and ensure the highest quality control in manufacturing. Energy dispersive X-ray fluorescence (EDXRF) is a simple and powerful technique for the analysis of elemental composition. A tip to meet the challenges of trace analyses and measurement of complex elemental composition is the use of Cartesian Geometry EDXRF. Rigaku NEX CG II EDXRF benchtop analyzer brings the latest innovations with Cartesian Geometry indirect excitation.

What is Cartesian Geometry EDXRF?

Cartesian Geometry is indirect excitation where the X-ray tube, secondary targets, sample, and detector are positioned at 90° angles. Secondary targets are used in the excitation beam path instead of traditional tube filters used in direct excitation XRF. The X-ray tube does not irradiate the sample directly but first beams off a secondary target, which is a metal or a carbon crystal. This allows for several advantages. When the source X-rays from the tube first irradiate a secondary target, the Bremsstrahlung background X-rays are essentially eliminated and replaced by the fluorescence of the target, creating monochromatic excitation with little or no background X-rays scattering to the detector. In the case of a carbon crystal as the secondary target, polarization is achieved when in the 90° angle, further reducing background for measuring the low energy light elements sodium through chlorine.

Innovation in EDXRF combines the Cartesian Geometry indirect excitation with updated electronics and a wide area high-performance silicon drift detector (SDD). The SDD EDXRF detector collects X-rays simultaneously and gives high count rate throughput with sharp resolution, or peak width, thus minimizing the need for element peak overlap corrections. Combined, the optics of Cartesian Geometry yield very low or no background and high X-ray intensity collection of net characteristic X-rays from each element without the detector throughput being filled with background X-rays. This allows for very low detection limits and the measurement of samples containing many elements.

Applications

Cartesian Geometry EDXRF is advantageous for analyzing many types of trace and complex applications. A shortlist follows here:

- Consumer goods, plastics and polymers, RoHS compliance, and manufacturing quality control of additives in polymers

- Agricultural soils and plant materials

- Measuring ultra-low sulfur and metals in petroleum fuels such as diesel and gasoline for ASTM, U.S. EPA compliance, and other international testing norms

- Trace particulate matter in air filters for air quality monitoring

- Reclaim precious catalysts, including refining catalysts in the petrochemical industry and automotive catalysts in used catalytic converters

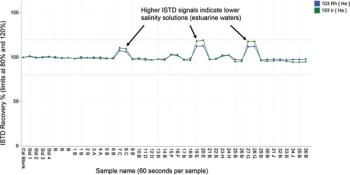

Figure 1 shows the measurement of low or trace platinum (Pt) in recycled automotive catalysts. Cartesian Geometry provides flat background and well-resolved peaks for the measurement of Pt in the presence of the other matrix elements from the converter honeycomb core, which include Al, Si, Ti, Fe, Ni, Cu, Zn, Pb, Rb, Sr, Y, Zr, Ba, La, Ce, Pr, and the other catalysts Pd and Rh.

Conclusion

Cartesian Geometry EDXRF is ideal for measuring ultra-low and trace element concentrations. It excels in complex applications with trace elements and variable base matrices, such as testing agricultural soils and plant materials, analyzing finished animal feeds, measuring waste oils, environmental monitoring, and many others.

Articles in this issue

over 4 years ago

Cryogenic Raman Imaging of a Tungsten Diselenide Flakeover 4 years ago

Optimizing Spectral Data Using a Variable Angle ATRover 4 years ago

Application Note: Raman Spectroscopy for Reaction Monitoringover 4 years ago

Laser Frequency Offset Lockingover 6 years ago

A Diamond ATR Study of Worn Surfaces on MetalNewsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.