- March 2021

- Volume 36

- Issue 3

Heavy Metals in Pet Food: Changes in Heavy Metal Contamination in Pet Food Over the Past Decade

Analysis of heavy metals in pet food using ICP–OES was conducted to determine if there were potentially toxic elements present. Many of the samples showed significant concentrations of various toxic metals.

Pet food is a multibillion dollar per year business that affects businesses and pet owners on a daily basis. Along with increased growth, there has been increased controversy. The melamine pet food scare of 2007 affected millions of people and their pets, along with the pet food industry. The pet food scare highlighted the potential for contaminants and controversial ingredients that could be contained in pet food. In addition to organic chemical contaminants and additives, there is also the possibility of toxic elemental contamination from protein sources, fillers, and manufacturing processes. Therefore, the search for “healthy” pet food goes beyond the choice of a name brand food or nutritious ingredients on a label.

Ten years ago, SPEX CertiPrep, first introduced its popular study on “Heavy Metals in Pet Food,” which was featured in Spectroscopy (1,2). The purpose of this 2009 study was to examine pet foods from a variety of sources to determine if there were potentially toxic elements present in the foods. Many of the pet foods sampled showed significant concentrations of various toxic metals. In many cases, the concentrations exceeded the extrapolated human limit values calculated to pet-size dosages.

In the intervening 10 years, the Food Safety Modernization Act (FSMA) was enacted, and pet food became one of the targets of scrutiny. This new 2019 study was produced as a joint effort between SPEX companies and CEM Corporation, and revisits pet food brands first analyzed in 2009, while looking at new brands that have emerged after the 2007 pet food crisis and later enactment of the FSMA, to determine whether heavy metal contamination has significantly changed in the decade following the first study. Using updated cryogenic and microwave technologies, samples were tested by inductively coupled plasma (ICP) and inductively coupled plasma–mass spectrometry (ICP–MS) to determine heavy metal content, and these results were compared to our previous 2009 study.

Recently, I presented a summary of our findings in an interview for Spectroscopy (3). The purpose of this article is to expand on those findings.

History

Some of the first commercial dog food has been credited to a businessman in the 1860s who developed a dog biscuit after he witnessed dogs being fed leftover hardtack biscuits in the ports of England. His idea later came to the United States in the late 1890s, but the canned pet food we know today did not exist extensively until after World War I (WWI). Ken-L-Ration brand (1922) was the first commercial pet food sold because of an excess of horse meat after WWI. In the early part of the 20th century, the U.S. Food and Drug Administration (FDA) did not exist, and only human food and medicine was under consideration of the 1906 Pure Food and Drug Act.

The first controls of pet food came under the 1938 Federal Food, Drug, and Cosmetic Act, which only required that pet food be safe to eat, produced under sanitary conditions, free from harmful substances, and labelled truthfully as to its quantity, identity, manufacturing process, ingredients (listed by weight), and nutritional information. The next significant advance of pet food also came after a major war when the consumer canned and packaged food companies that grew out of war rations, then transitioned to a post war economy. These companies capitalized on the ability to use human food by-products to create pet food.

Extruded dry kibble began to appear in the mid-1950s, and the pet food industry flourished and became mainstream, ultimately growing into a multibillion dollar a year global industry. The 1960s saw increases in specialized pet foods and an increase in brands and product lines for established companies. The first big public scare in the pet food industry started with the 2007 discovery of melamine and cyanuric acid in a wide range of pet food varieties and brands. Early in 2007, there were hundreds of pet deaths and illnesses because of kidney failure around the world, which was later traced back to illegal protein adulteration. Chinese raw material manufacturers had added the melamine to the pet food to artificially increase the protein content. Over 5000 product recalls were announced across multiple brands, manufacturers, and suppliers, linked to almost 10,000 pet deaths and illnesses.

2009 Heavy Metals Study

For years after the melamine pet food disaster, pet owners continued to be concerned about their pet’s food. The initial disaster happened because of terrible oversight of supply chains and lack of testing for harmful ingredients. The pet food industry claimed that, as a result of the melamine scare, there was more active policing in their industry and products, but questions still remained whether pet food was safe or not. In 2009, SPEX CertiPrep made a decision to look at the elemental content of pet food. SPEX CertiPrep was a close-knit family company whose employees and owners were dedicated pet owners. The study solicited pet food from all the employees, and purchased food from local pet stores, groceries, dollar stores, and supercenters. We decided to investigate all price ranges, from the cheapest dollar store food to the boutique gourmet brands sold in specialty markets. The original study was conducted in the winter of 2009–2010, covering almost sixty samples. The samples included approximately equal amounts of cat and dog foods, as well as equal amounts of wet canned food and dry kibble.

Once the foods had been grounded, digested, and tested, it was found that there were substantially high amounts (up to ppm levels) of heavy metals and wear metals (from the processing equipment) in pet food, especially in dry kibbles. The amount of food that owners fed their pets increased the exposure of pets to higher levels of potentially toxic metals. Despite the fact that pet food had been under the control of the FDA since 1938, there was no guidance in 2009 regarding the limits for the most toxic elements to dogs and cats. Instead, the SPEX CertiPrep study used human exposure guidelines issued by the EPA and scaled them to a standardized size (50 lbs for a dog and 10 lbs for a cat).

In the decade since the first heavy metals study, the FSMA was created. Pet food fell under the direction of the FDA within the FSMA, and it was our hope that public awareness of the previous pet food regulatory shortfalls would be corrected and lower metal content would now be seen in pet food.

Experimental

The basic techniques, materials, and methods for both the 2009 and 2019 studies were similar. Differences in the studies included the use of updated equipment and instrumentation, which will be discussed within the “Methods” section. For details on the previous 2009 experimental conditions, please refer to the originally published articles published in Spectroscopy in 2011 (1,2).

Reagents and Standards

In both the 2009 and 2019 studies, concentrated optima-grade nitric acid was obtained from Fisher Scientific. Deionized water was obtained from an in-house laboratory water filtration and processing system, which produces deionized water (ASTM I grade).

The SPEX CertiPrep standards (SPEX CertiPrep Group) used in both studies included:

- CLMS-2N: Claritas Multielement Solution Standard

- (10 mg/L: Ag, Al, As, Ba, Be, Bi, Ca, Cd, Co, Cr, Cs, Cu, Fe, Ga, In, K, Li, Mg, Mn, Na, Ni, Pb, Rb, Se, Sr, Tl, U, V, and Zn)

- CL-ICV-1: Claritas Initial Calibration Verification 1

- (1000 mg/L: Fe, K, Ca, Na, Mg, Sr; 10 mg/L: Ag, Al, As, Ba, Be, Cd, Co, Cr, Cu, Mn, Mo, Ni, Pb, Sb, Se, Tl, V, Zn, Th, and U)

- CLU2-2Y: Claritas Uranium Single Ele- ment Standard (1000 mg/L)

- CLHG2-1AY: Claritas Mercury Single Element Standard (10 mg/L)

Standards were diluted to μg/kg concentrations appropriate for ICP– MS analysis in 5% nitric acid in deionized water solution to match the acid matrix of samples. Standards of 0.1, 0.4, 1.0, 4.0, and 10 μg/kg, were made up in 5% HNO3, and matrix matched for ICP–MS calibration.

Blank Preparations

Optima-grade nitric acid used in digestion was added to the deionized water blanks prior to analysis in a comparable concentration as to the acid concentration found in the pet food samples. In addition to water blanks, optima-grade nitric acid was processed as a sample in the microwave vessel to determine contamination from the polytetrafluoroethylene (PFTE) vessels or any memory effects of the previous samples. After each pet food sample digestion run, 10 mL of nitric acid were digested discarded from the microwave vessels to clean vessels. A second 10 mL digestion of nitric acid was then repeated, and the digest was diluted in the same method as the pet food samples and treated as a vessel blank.

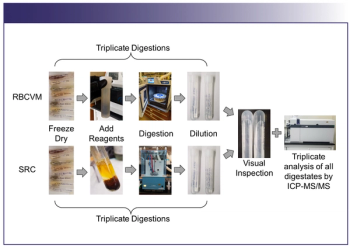

Sample Collection, Preparation, and Digestion

For this investigation, a total of 61 different cat and dog foods were bought from local stores or donated by employees of the SPEX companies and CEM Corporation. The samples consisted of dry food varieties. Of the 60 dry foods, 37 of them were dog food, and 23 of them were cat food samples. The range of quality of the pet foods was from “discount” to “gourmet brands.” Pet food prices ranged from the “bargain” store foods priced at 0.02¢ per ounce to gourmet or specialty foods purchased from pet suppliers priced above 0.42¢ per ounce. There are 11 samples that were similar or identical to brands or varieties studied in the original 2009 study.

Dry cat and dog food samples (10–15 g) were ground to a uniform powder in a cryogenic mill (SPEX SamplePrep 6875D Large Dual Freezer/Mill with 6885 mid-size Poly-Vial). Operating conditions are shown in Table I.

One half gram of the powdered or blended sample was digested with 10 ml of nitric acid in a CEM Mars-6 microwave oven (CEM Corporation) using a preprogrammed pet food method. After digestion, samples were diluted to 50 mL volume with deionized water. Prior to analysis, samples were diluted to a final concentration of 1000x using deionized water.

Instrument Conditions

Primary sample analysis was conducted using a PerkinElmer inductively coupled plasma–optical emission spectrometer (ICP–OES) (PerkinElmer Inc.). The ICP–OES was used to determine the macro-elemental composition of the foods to select standards which would allow for correct matrix interferences. Elements measured by ICP–OES included aluminum, calcium, copper, iron, magnesium, manganese, phosphorus, potassium, selenium, silicon, sodium, sulfur, and zinc.

All trace element determinations were carried out using the Agilent 7900 ICP–MS (Agilent Technologies). It can be seen that multiple isotopes were used for many of the elements to evaluate the spectral complexity of the samples and also for mathematical equation correction purposes. Wherever possible, the most sensitive isotope free of spectral interferences was chosen for the quantitation.

Results and Discussion

Heavy Metal Concentrations 2009 and 2019

In 2009, there were significant amounts of metals found in the pet food, with 215 ppm aluminum and over 1 ppm of several potentially toxic metals, including chromium (2.5 ppm), nickel (3.2 ppm), lead (6 ppm), and tin (9.4 ppm). There was 0.5 to 1 ppm of antimony and cobalt. Some foods had correlations of ppm levels of nickel and tin showing large amounts of potential wear metal contamination from the manufacturing equipment. There was even uranium detected in several samples up to 1 ppm.

The samples from 2019 still showed heavy metal contamination, including twice the amount of uranium (1.7 ppm), and three times the amount of arsenic (0.7 ppm). Lead levels were significantly lower overall in the 2019 samples with a maximum of 0.5 ppm, as shown in Table II.

In 2009, one of the surprises resulting from the analysis was the discovery of up to 1 ppm of uranium in the pet food samples. Later, it was discovered there was a correlation of samples containing uranium also having significant levels of beryllium and thorium, as shown in Figure 1.

In the 2019 study, the levels of uranium, beryllium, and thorium were again examined, and it was found that the 2019 samples had a greater number of samples that contained significant uranium levels than in 2009. The samples set for 2019 contained fourteen samples over 250 ppb compared to only six samples in 2009. Most of the 2019 samples were dry dog foods, which was also consistent with the 2009 study, but in the updated samples, there were two dry cat foods which also measured over 250 ppb, whereas in 2009 there were only dry dog food samples. Nine 2019 samples contained over 500 ppb and four had over 1 ppm, with the highest sample at 1.7 ppm of uranium.

Exposure and Daily Limits

In 2009, as was stated earlier, there were no limits or guidelines for heavy metals in pet food, so limits were used for human exposure from the U.S. Environmental Protection Agency (EPA) and World Health Organization (WHO). Average pet size was standardized to 50 lbs for a dog and 10 lbs for a cat. At the time of the 2009 study, a survey of feeding habits was conducted amongst the owners of the donated pet food. Most owners in general fed their pet approximately one cup of food per 10 lbs of body weight per day. After the publication of the study, some parties (pet food companies) expressed concern and criticism for the amount of food being fed and therefore the potential elemental exposure. In light of these comments, in the 2019 study, veterinary guidelines for the feeding of pets limited the food consumption to approximately three cups of dry dog food and one-half cup of dry cat food daily.

During the interim between studies, the 2011 FSMA was implemented. In the act, there was further guidance on the safety of pet food, but, again, no limits were expressed for heavy metals or toxic elements in pet food so updated human limits from the WHO and the EPA were used as guidelines. Reference daily dosages (RfD) and tolerable daily intake (TDI) for the pets were calculated (Tables III and IV) to estimate exposure from the various foods tested.

Dog Food Exposure Results

The 2019 samples results were calculated for a serving of three cups of dry dog food intended for a 50-lb dog (Table V) and compared to calculated limits (Table III). Mercury results were not included in 2019 data because of technical issues.

The exposure for many of the elements increased from 2009 to 2019 as well as the proportion of samples with high levels of metals. In 2009, arsenic was high for 44% of dog food samples, but in 2019, 70% of samples exceeded the highest WHO daily limit for 50 lbs of body weight. Nickel exposure overages also increased from 22%, exceeding limits in 2009 to almost 46% over in 2019. Some exposures for lead and cadmium dropped from 2009 to 2019. Lead dropped from 22% over limit in 2009 to 11% over in 2019. Cadmium dropped from 28 to 19% over RfD.

The concentration of heavy or toxic metals in the food increased for most elements, with higher mean and maximum results in 2019 compared to the results from 2009 (Table V). In both studies, the maximum measured elemental content approached or exceeded allowable daily limits of exposure. In 2009, arsenic concentration was 84 (mean) to 152% of the limit, but in 2019, arsenic ranged from 153 (mean) to 420% (maximum) of the highest WHO limit, as seen in Table VI.

Cat Food Exposure Results

Cat food, similar to dog food, found increases in concentrations of trace elements from 2009 to 2019. The total number of samples with levels that exceeded limits increased as did the overall concentrations of elements, such as arsenic, nickel, and uranium. The majority of cat food samples had arsenic levels above the WHO TDI. The highest samples contained over 400% the limit. As was found in the dog food, lead levels were slightly lower in the 2019 samples compared to the 2009 data, as seen in Tables VII.

Conclusions

The quality control procedures used in the past to produce cat and dog food were not equal to foods for human consumption as was shown in the 2009 study. This fact was particularly apparent in dry cat and dog food formulas, which might contain up to a dozen different ingredients, such as animal parts, meat byproducts, cereals, fillers, nutrients, and essential minerals.

The enactment of the FSMA did include pet food in the scope of food safety, but still there are no definitive limits for heavy and toxic metals for pet food which can either be derived from raw materials (such as fillers, grains, cereals, or meals) or processing equipment. Essential minerals like calcium and phosphorus are manufactured from industrial chemicals, which could possibly contain other trace metal impurities. The purpose of the original study and the updated 2019 study was not to track down the source of the elements and contamination found in pet food, but an attempt to evaluate significant levels of metals in the food.

The interest in this study and its predecessor becomes relevant when the data is compared to the EPA RfD and WHO TDI values. These are guidelines that are set down by experts in the scientific, medical, and health care communities, based on decades of research into toxicity. In lieu of validated limits for dogs and cats, we choose to be cautious and use the human limits to compare exposure levels potentially found in an animal’s daily consumption of dry pet food.

The metal content of many of the different pet foods is significantly higher than EPA and WHO values, when adjusted for the average weight of a dog and cat. We do not know the chemical composition or speciation of the heavy metals found in these foods, and therefore, we do not know their uptake or bioavailability, and we also do not know if the EPA RfD and WHO TDI values apply the same to animal physiology.

The 10 years between the two pet food studies did not show any major drops in heavy metal contamination despite the enactment of the FSMA. Some of the lead levels have dropped but other potentially toxic metals have increased, including arsenic, nickel, and uranium. The 2019 samples showed uranium in cat food unlike the 2009 study which only found uranium in the dog foods. There are many studies regarding heavy metals and toxic metals in human foods which go undetected, so it is not surprising that pet food is still not comprehensively tested for metals contamination.

Acknowledgments

The updated 2019 study is a joint effort between the scientific teams and employees of SPEX CertiPrep, SPEX SamplePrep, and CEM Corporation. Special acknowledgement for the sample grinding conducted by Eric Smith of SPEX SamplePrep and sample preparation and digestion by the team at CEM, including Tina Restivo, Bob Lockerman, and Macy Harris. I would also like to acknowledge the SPEX CertiPrep inorganic analytical team, including William Green, Katherine Cullen, and Alan H. Katz, as well as many other assistants, chemists, and technicians in the SPEX Inorganics department, without whom the data would never have been processed.

References

(1) P. Atkins, L. Ernyei, W. Driscoll, R. Obenauf, and R. Thomas, Spectroscopy 26(1), 46–56 (2011).

(2) P. Atkins, L. Ernyei, W. Driscoll, R. Obenauf, and R. Thomas, Spectroscopy 26(2), 42–59 (2011).

(3) L. Bush, Spectroscopy 35(12), 22 (2020).

ABOUT THE AUTHORS

Patti Atkins is a Senior Applications Scientist at SPEX CertPrep and a member many scientific committees, including NACRW, AOAC and ASTM. Tina Restivo is a Senior Scientist at CEM Corp. Bob Lockerman is the Global Analytical Product Manager for the MARS 6 microwave digestion system at CEM Corp. Direct correspondence to:

ABOUT THE COLUMN EDITOR

Robert Thomas is the principal of Scientific Solutions, an educational consulting company that serves the training and writing needs of the trace element user community. He has worked in the field of atomic and mass spectroscopy for more than 45 years. ●

Articles in this issue

almost 5 years ago

Library Searchingalmost 5 years ago

Combined Raman and Photoluminescence Imaging of Two-Dimensional WS2Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.