Determination of Elemental Impurities in a Nasal Spray Using ICP-MS

A tutorial and spreadsheet for the validation and bottom-up uncertainty evaluation of quantifications performed by instrumental methods of analysis based on linear weighted calibrations were presented by Ricardo J.N. Bettencourt da Silva of the University of Lisbon in Lisbon, Portugal, and colleagues. This software tool was successfully applied to the determination of the mass concentration of Cd, Pb, As, Hg, Co, V, and Ni in a nasal spray by ICP-MS after samples dilution and acidification. Bettencourt da Silva spoke to Spectroscopy about applying this software tool and the implications for a better understanding of quantitative analytical results.

A tutorial and spreadsheet for the validation and bottom-up uncertainty evaluation of quantifications performed by instrumental methods of analysis based on linear weighted calibrations were presented by Ricardo J.N. Bettencourt da Silva of the University of Lisbon in Lisbon, Portugal, and colleagues. This software tool was successfully applied to the determination of the mass concentration of Cd, Pb, As, Hg, Co, V, and Ni in a nasal spray by ICP-MS after samples dilution and acidification. Bettencourt da Silva spoke to Spectroscopy about applying this software tool and the implications for a better understanding of quantitative analytical results.

Instrumental methods of analysis are frequently used to determine the level of a compound, class of compounds, or other chemical property on the studied item. The ability to adequately quantify measurement result uncertainty is crucial for the objective that triggered the chemical analysis. A tutorial and spreadsheet for the validation and bottom-up uncertainty evaluation of quantifications performed by instrumental methods of analysis based on linear weighted calibrations were presented by Ricardo J.N. Bettencourt da Silva of the University of Lisbon in Lisbon, Portugal, and colleagues. This software tool was successfully applied to the determination of the mass concentration of Cd, Pb, As, Hg, Co, V, and Ni in a nasal spray by ICP-MS after samples dilution and acidification. Bettencourt da Silva spoke to Spectroscopy about applying this software tool and the implications for a better understanding of quantitative analytical results.

Your recent paper (1) describes a tutorial and spreadsheet for the validation and bottom-up uncertainty evaluation for quantitative instrumental methods based on a linear weighted regression model. Why do you believe that there is a need for such a tool? What sort of information or insight does it provide that currently available methods or tools do not?

The developed tool has two merits: the ability to make accessible complex uncertainty evaluations, and the novelty of allowing evaluating the uncertainty from weighted calibrations without the need to collect many replicate signals of calibrators. The paper includes a user-friendly MS-Excel file that can be used to assess the assumptions and evaluate the uncertainty from linear weighted calibrations of instrumental methods of analysis. It is provided with metrological and statistical tools to test the calibrator’s quality and instrumental response linearity where different weighting factors can be selected according to how precision varies in the calibration interval. The disadvantage of weighted regression models of requiring the reliable determination of signal precision in each calibration to better set the weighting factors is overcome by defining precision models that can be updated with the residual standard deviation estimated from daily calibrations based on a few replicate signals.

This tool is particularly useful because most instrumental methods of analysis are calibrated in intervals where the signal varies linearly with the studied quantity, typically the concentration of an analyte, and the signal’s precision varies in that interval. Before the publication of this paper, such a tool was not available that can be easily integrated into the daily activities of test laboratories.

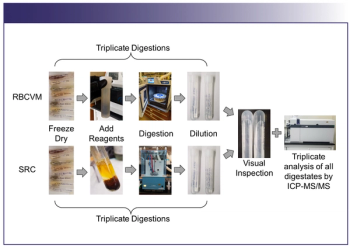

Your spreadsheet tool was successfully applied to the quantitative determination of the mass concentration of Cd, Pb, As, Hg, Co, V, and Ni in a nasal spray by ICP-MS after sample dilution and acidification. What made you decide to choose this particular application to test your tool? What benefits did the utilization of this spreadsheet bring to the analysis?

This application was selected due to the relevance of the quality control of medicines and because these analyses do not include a complex sample preparation that constitutes an additional relevant uncertainty component. In these analyses performed by experts from the Palacky University in Olomouc (Czechia) in their GMP certified laboratory

Briefly discuss your findings and their implications for a better understanding of quantitative analytical results.

The paper presents experimental evidence of the adequacy of the developed measurement uncertainty models and constitutes a relevant contribution to the democratization (making the tool accessible to everyone). of complex measurement uncertainty evaluations. The quantification of measurement uncertainty is crucial to guarantee that performed analyses are fit for purpose and have known quality. Measurement results are only valid for a specific purpose if their uncertainty is adequately low. The measurement uncertainty is also crucial for the sound and objective interpretation of the analytical information.

What are the biggest challenges that you have encountered in developing this tool? What options or alternative developments are available to overcome these challenges or to improve this spreadsheet approach?

The biggest challenges we have faced in developing this tool were making it user-friendly and avoiding the need to collect many replicate signals for the daily calibration of an instrumental method of analysis based on the linear weighted regression model. Some authors have developed software for evaluating the uncertainty of instrumental quantifications that require demanding and not supervised collections of input data. A spreadsheet for the Monte Carlo simulation of instrumental quantification uncertainty was also developed but requires some computational resources for the simulation.

What sort of feedback did you receive from this paper and the study results?

We have received very positive feedback from the pharmaceutical industry that is becoming more interested in measurement uncertainty evaluations to guarantee conformity assessment reliability. However, the developed tool can be applied to any instrumental method of analysis.

What are your next steps regarding this research? Are there any additional analytical approaches or methods where this tool might be beneficial?

We are developing equivalent tools for non-linear regressions and integrating complex sample preparation in analytical methods based on instrumental quantification. These research efforts will involve the development of new metrological tools and their democratization through tutorials and user-friendly software.

Reference

(1) T. Pluháček, D. Milde, J. Součková, and R.J.N. Bettencourt da Silva, Talanta 225,122044 (2021).

Ricardo Bettencourt da Silva, after working in accredited laboratories as an analyst and consultant for 15 years, started a research and teaching career at the University of Lisbon. Since 2002, collaborates with the Portuguese Accreditation Body, as technical assessor, and trains the staff of laboratories. Ricardo is currently the secretary of CITAC, a member of the executive board, chair of the working group on Qualitative Analysis, and a member of the working group on Measurement Uncertainty and Traceability of Eurachem. He is co-editor of the Eurachem/CITAC guide for Setting the Target Measurement Uncertainty. His research interests are Metrology and Examinology in chemistry, the sciences of measurements, and qualitative analysis in chemistry, respectively.

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.