News

Article

Application Notebook

Automated Macro-Mapping a Coating via Reflection Sampling

Author(s):

Using an automated FT-IR reflection sampling accessory, the surface of a polymer-coated aluminum film was analyzed. Spectral results were used to investigate chemical uniformity across the sample area.

Using an automated FT-IR reflection sampling accessory, the surface of a polymer-coated aluminum film was analyzed. Spectral results were used to investigate chemical uniformity across the sample area.

Having the capability to map several spots of a solid sample via FT-IR analysis is useful to investigate uniformity of new chemical formulations and effects of processing parameters. By incorporating automated sampling, more consistent and reliable results may be obtained because the sample is not removed from the accessory between measurements for area analysis. Additionally, automation improves productivity by freeing time to accomplish other tasks and reducing the possibility of user error.

Materials and Methods

PIKE Technologies’ XY Autosampler diffuse/specular reflection accessory was used to automate mid infrared spectral mapping of a polymer-coated aluminum foil surface.

The XY Autosampler fits into the sample compartment of most commercial FT-IR instruments. Its precision XY stage accepts a sample plate with a microtiter plate footprint (85 × 128 mm). Sixteen scans were co-added using a resolution of 4 cm-1. Scanning range was from 7000 to 400 cm-1.

For this investigation, a custom clamshell sampling plate ensured foil flatness during the measurements. Eighteen points were analyzed on the sample, which was 65 x 128 mm. Data presented were baseline corrected.

Results

The optical layout of the XY Autosampler is based upon a precision ellipsoidal collection mirror that condenses the beam onto the sample with a power of approximately 3x. A typical 9-mm beam size results in roughly a 3-mm spot on the sample. The beam strikes the sample at a 30° angle of incidence.

Specular reflection sampling in the mid infrared is a useful technique for measuring thin coatings on reflective substrates and analyzing of bulk materials. In the case of a relatively thin film on a reflective substrate, like the polymer-coated foil sample measured here, the specular reflection experiment may be thought of as a “double-pass transmission” measurement because the beam passes through the coating, reflects off the substrate, and once again passes through the coating.

For samples with coating thickness in micrometers, results are very sensitive when using specular reflection accessories with angles of incidence at near normal (10o) and greater.

Typically, the resulting IR spectrum of a coating on a reflective substrate collected via specular reflection sampling is easily searchable in a spectral database library because it appears similar to a transmission spectrum. For the spectra collected here, a high-quality database match was found against a styrene-acrylic polymer coating. This match quality was consistent across the macro-mapping area.

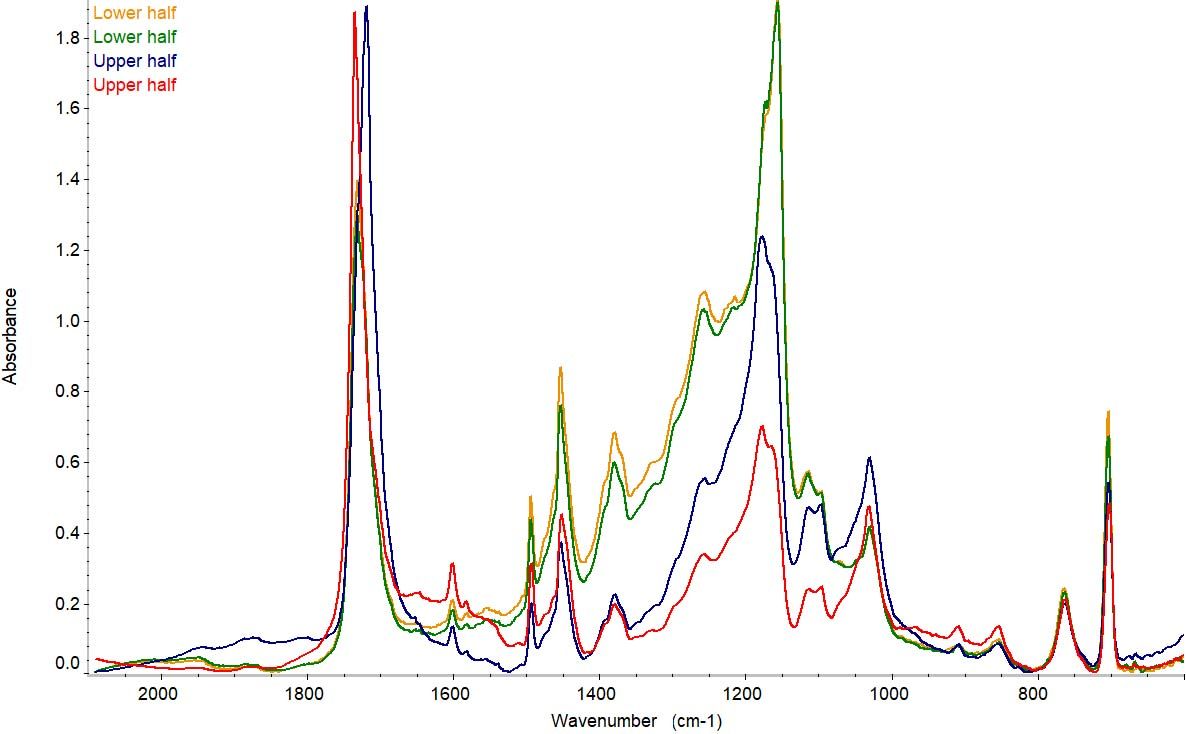

A subset of the data is presented here for presentation clarity (Figure 1). Upon a closer inspection of the fingerprint region, there are some small differences as a function of position (upper versus lower area of the sample foil) in the spectral band shapes and band ratios at 1180, 1160, 1120, and 1100 cm-1. This would suggest that either the chemical composition of the coating was slightly different in these areas or that processing conditions could be responsible.

Figure 1: Select spectra of the coating on a foil; two from the upper and two from the lower area of the sample.

Conclusion

In addition to measuring individual samples by diffuse reflection, the XY Autosampler also offers a versatile platform for mapping the surface of a one-piece solid by specular/diffuse reflection to evaluate chemical uniformity across a sample.

PIKE Technologies, Inc.

6125 Cottonwood Drive, Madison, WI 53719

Tel. (608) 274-2721, Fax (608) 274-0103

www.piketech.com

Newsletter

Get essential updates on the latest spectroscopy technologies, regulatory standards, and best practices—subscribe today to Spectroscopy.