Why do industry leaders attend the Gulf Coast Conference (GCC)? Jean-François Borny, Global Analytical Services Senior Manager at Lummus Technology and Technical Chair of GCC, shares his perspective.

Why do industry leaders attend the Gulf Coast Conference (GCC)? Jean-François Borny, Global Analytical Services Senior Manager at Lummus Technology and Technical Chair of GCC, shares his perspective.

In this episode, a global panel of experts examines how trace elements and material impurities affect lithium-ion battery performance, longevity, and safety, and explores how ICP-OES and ICP-MS applied across the entire value chain—from raw material sourcing to recycling—can optimize first-pass yield, ensure quality control, and support more sustainable manufacturing practices.

Experts explore the evolving role of CDMOs in semiconductor fabrication and why strategic partnerships are increasingly critical for process innovation and cost control.

Looking ahead, panelists discuss emerging technologies, new analytical frontiers, and future regulatory pressures shaping semiconductor manufacturing over the next decade.

The panel takes a deep dive into total chemical and gas management (TCGM) strategies, and the growing need for online, real-time monitoring to protect yield and safety.

Panelists discuss cutting-edge advances in monitoring ultra-pure water (UPW) purity, from ICP-MS to online pre-concentration, and the growing push for sub-ppt-level contaminant detection.

The panelists discuss the vital role of ultra-pure water (UPW) and recycled water strategies to support yield, safety, and environmental compliance.

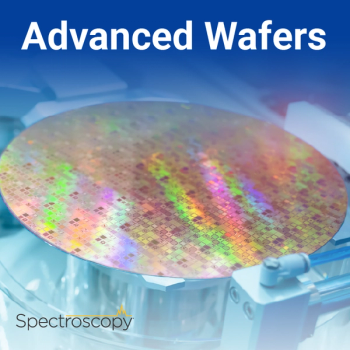

The panel discusses how silicon (Si), silicon carbide (SiC), and gallium nitride (GaN) materials influence semiconductor design choices, yield challenges, and supply chain risks.

This episode takes a look at the evolving regulatory environment in semiconductor manufacturing, including stricter contamination standards and the challenges of global compliance.

The panelists consider non-destructive wafer analysis using TXRF and complementary methods, and how combining techniques enables advanced defect and contamination mapping.

In this episode, the panel focuses on automation in semiconductor analysis, including sample prep innovations and the unique capabilities of next-generation ICP-MS systems.

The panel compares traditional ATD-GC-MS methods to emerging TOF-MS approaches for impurity and defect analysis, emphasizing speed and sensitivity advancements.

The panelists discuss the different techniques used for testing semiconductor materials—such as ICP-MS, VPD, GDI, and GED-ICP-MS—including which approaches the industry will adopt more moving forward.

Ruth Merrifield, PhD, discusses how continuous manufacturing can help control contamination as humans don’t have to touch the materials as often, or even at all. Katsu Kawabata also mentions how automation that supports continuous manufacturing can help reduce human exposure to chemicals that would otherwise be manually handled.

Panelists discuss primary bottlenecks in semiconductor manufacturing, from geopolitical supply chain issues to purity and talent gaps, and explore strategies to maintain innovation under pressure.

Experts from across the industry prepare to explore the critical efficiency hurdles semiconductor fabricators are facing today, introducing themselves and their backgrounds.

Dr Adam J. Hopkins, Metrohm, highlights the capabilities of the OMNIS near-infrared technology platform for more efficient and advanced sampling of liquids and solids.

Learn about PerkinElmer’s key innovations for trace elemental analysis.

Witness multiple scenarios in elemental analysis laboratories that provide quantitative evidence on how decisions related to sample preparation workflows can affect a lab’s performance.

Discover practical ways to prevent contamination during sample preparation for trace elemental analysis, including sampling practices, in-house acid purification, and automated reagent addition. Benefits include lower detection limits, reduced reagent costs, and a safer working environment.

Using acid baths and microwave systems for cleaning labware can have a substantial impact on an elemental analysis lab’s throughput, workflow, and efficiency. Learn how automating this step using acid-steam cleaning keeps your microwave system focused on digesting samples and removes the tedium and hazards of hand-cleaning labware.

Using acid baths and microwave systems for cleaning labware can have a substantial impact on an elemental analysis lab’s throughput, workflow, and efficiency. Learn how automating this step using acid-steam cleaning keeps your microwave system focused on digesting samples and removes the tedium and hazards of hand-cleaning labware.

In this video interview, Erica Cahoon, PerkinElmer’s Atomic Spectroscopy Portfolio Director, provides an introduction to the new NexION® 1100 ICP-MS, specifically designed for laboratories looking for a reliable, yet easy-to-use solution for everyday trace-elemental analyses applications.

AgSource analyzes from 2,000 to 6,000 samples in a day, depending on the time of the year. Accuracy is critical for AgSource. Time and time again, they want to be as accurate as possible and be able to reproduce that accuracy with those same samples that come in over time.

Product origin and production claims, like sustainable and ethical sourcing, are vital information for consumers. It’s not just the product that matters anymore but also the promise. These promises are becoming as important, in some situations, more important than price and other product features.

Dr. David Creasey (CEO, Wasatch Photonics) introduces their X series spectrometers for Raman spectroscopy, highlighting best use and applications.

Shimadzu’s AIRsight infrared Raman microscope delivers more accurate results and improves operational efficiency by enabling both infrared and Raman measurements from the same position without moving the sample. This combined system saves valuable bench space while providing for easier operation with software that easily switches between infrared and Raman measurements via the same window.