There is no doubt that funding for basic science in analytical atomic spectroscopy has waned over the years, and, in reality, barely exists today.

There is no doubt that funding for basic science in analytical atomic spectroscopy has waned over the years, and, in reality, barely exists today.

Great interest has recently aroused in the study of the dysregulation of chemical elements within tissues. Information about the distribution of elements in biological tissues can contribute to a more complete medical diagnosis, and can guide therapeutic procedures for many pathologies.

An ongoing challenge within the forensic science community is the development of consistent report and testimony language that conveys results in a meaningful manner.

“It was a dark and stormy night…” Everyone should begin at least one paper, story, or other publication with that well-worn phrase. This was my chance.

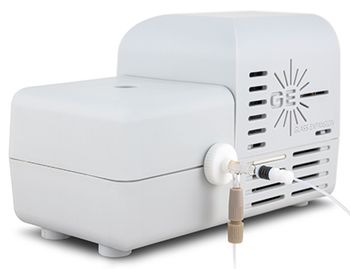

Glass Expansion designed and patented the D-Torch, a revolutionary, demountable torch. The D-Torch uses high-precision engineering to provide the benefits of a demountable torch, such as lower running costs, chemical inertness, and configurable injector geometry, without compromising usability, performance, or durability. In this report, we discuss the effects of harsh matrices on torches, as well as the features, benefits, and improvements in analysis achieved with the D-Torch.

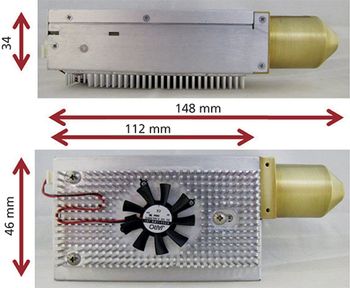

Moxi™ X-ray source is calibrated to within ±250 V over all settings between 5 to 50 kV. This impressive accuracy and precision is achieved spectroscopically, by measuring an X-ray spectrum's bremsstrahlung edge and storing correction high voltage offset information on each source.

The analysis of organic chloride in crude is demonstrated per ASTM D4929 Part C using Monochromatic EDXRF (MEDXRF).

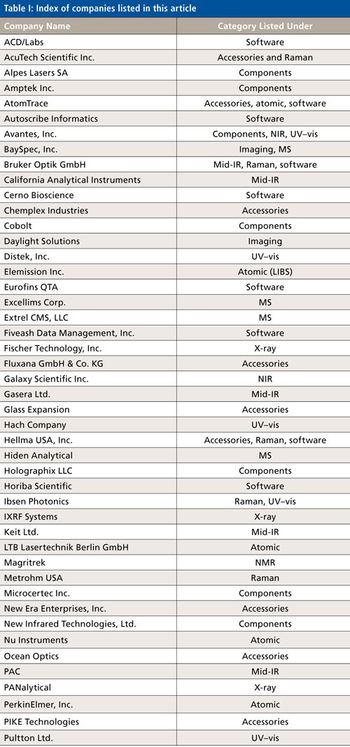

Our annual review of new spectroscopy products introduced at Pittcon, or during the previous year.

Cement is one of the most important materials for construction. ASTM C114-11 covers chemical analysis of hydraulic cement. XRF spectrometry is used for chemical composition analysis of cement due to its simple sample preparation and high precision. This application note demonstrates quantitative analysis for Portland cement by the pressed powder method according to ASTM C114-11 on the Rigaku Supermini200, a benchtop sequential wavelength dispersive XRF spectrometer.

The measurement of zirconium (Zr) conversion coating on aluminum is demonstrated.

Black pepper is often subject to counterfeiting and adulteration. Creating elemental profiles for an individual spice can be used as a tool to identify possible adulteration.

The measurement of gold is demonstrated in used ore material such as that from ore dumps and tailing piles. The recovery of uranium from the used ore material is also presented. The results how the Rigaku NEX DE EDXRF can achieve excellent results for monitoring and measuring the concentration of gold and other valuable elements in the recovery of used ore materials.

Teledyne Leeman Labs QuickTrace® M7600 was used to analyze and determine total elemental mercury (Hg0) concentration in Tuna (CRM 463) following the guidance in USDA Method CLG-MERC1.01 and the operating conditions.

A PFA cyclonic spray chamber was used with an HR-ICP-MS for the measurement of trace element/calcium ratios in foraminiferal calcite. The signal stability and washout were studied.

The measurement of chromium (Cr) conversion coating on aluminum is demonstrated.

The measurement of Cr, Hg, Pb, Br and Cd in polyethylene (PE) is demonstrated for RoHS rapid screening by XRF. Energy Dispersive X-ray Fluorescence (EDXRF) is employed for rapid screening and quantification according to RoHS norms.

Guide to Speciation: What is Speciation? Who Should be Concerned with Speciation Testing? What are the Obstacles to Adapting to Speciation Testing?

Quality control and quality assurance during the lube oil blending and manufacturing process is essential. Basic lube oil formulations containing only P, S, Ca and Zn are often augmented with additional elements and additives to create lubricating oils for specific needs.. This report demonstrates the measurement of Mg, Si, P, S, Cl, Ca, Zn, Ba and Mo in new lube oils is using the empirical approach.

Preparing soil samples for pesticide analysis is a crucial step in ensuring the safety of all consumers. Typical soil samples for analysis are often a heterogeneous mix that are unable to be directly analyzed; thus, the handling and homogenizing of the sample must conducted with the proper tools and techniques in order to obtain a reproducible and meaningful result.

Semi-quantitative analysis in modern XRF instruments is a unique method which is performed without reference materials for the unknown samples. This report demonstrates determination of chemical composition in geological samples using semi-quantitative analysis by the pressed powder method on a WDXRF spectrometer.